3D Fibre Matrix Ditch Liner

1.Construction cycle

Reach 80% strength in 24 hours, no curing required

2.Material consumption

Reduced by 95%, lightweight

3.Terrain adaptability

Can bend and fit complex curved surfaces

4.Waterproof property

Comes with a PVC backing, completely waterproof

5.Ecological impact

Low-carbon and low-alkali, can be combined with vegetation growth

6.Emergency response ability

Quick laying, suitable for emergency rescue and disaster relief

Product Introduction:

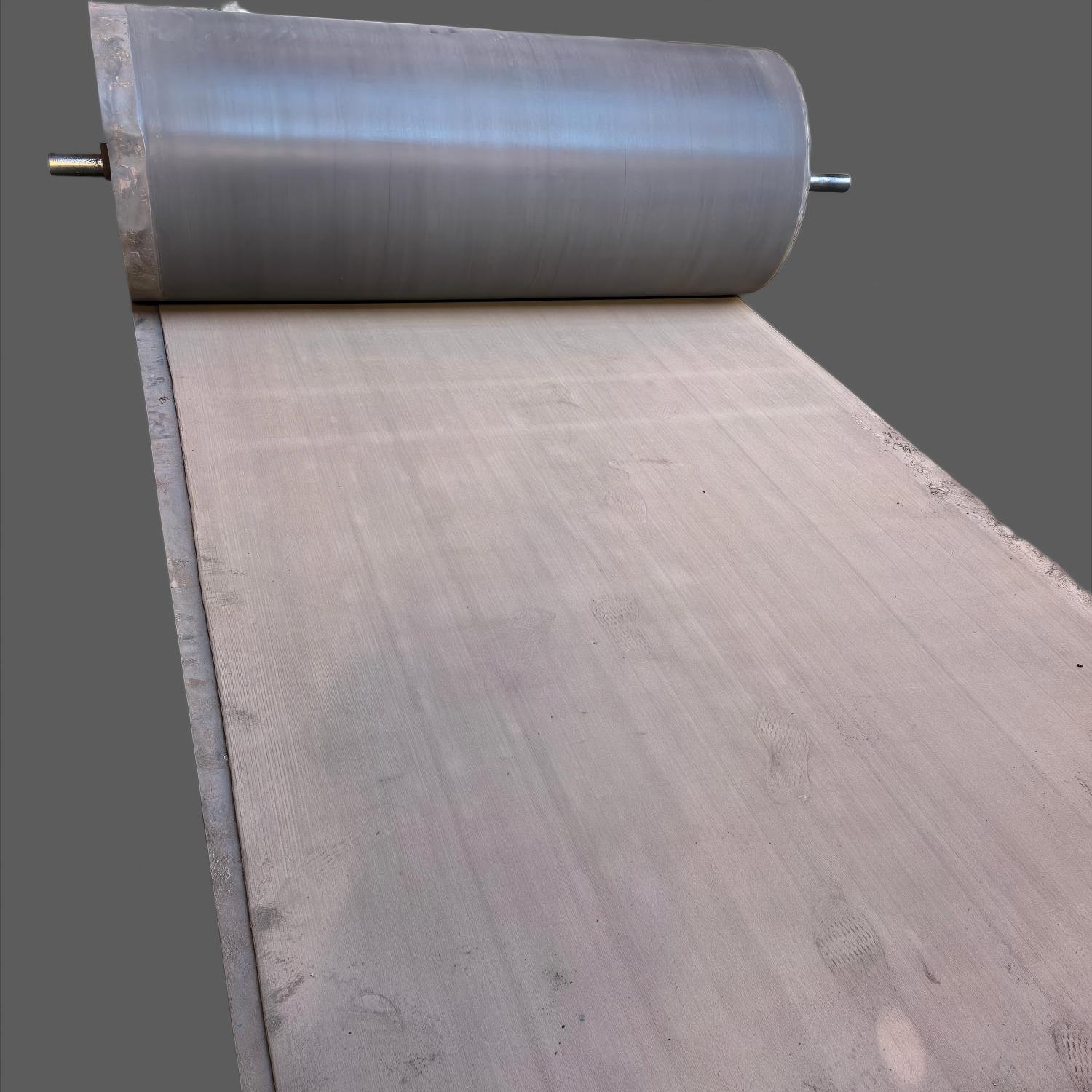

3D Fibre Matrix Ditch Liner (commonly known as Ditch Liner) is a flexible, fabric-like material impregnated with cement.

Component Structure:

It is mainly composed of a three-dimensional fiber composite structure woven from polyethylene and polypropylene filaments, a dry concrete mixture with a special formula, and a polyvinyl chloride (PVC) bottom liner on the bottom surface. The calcium aluminate cement in the dry concrete mixture has chemical components including Al₂O₃, CaO, SiO₂, Fe₂O₃, etc. The PVC bottom liner plays the role of waterproofing and enhancing chemical resistance.

It is widely applied in fields such as railways, highways, water conservancy, and agricultural irrigation, and is used in projects such as slope protection, anti-seepage, and structural protection. For example, it is used in the construction and protection of agricultural irrigation canals, industrial and civil drainage ditches, railway embankment drainage ditches, and highway drainage ditches. It can also be used to build temporary shelters, temporary housing in disaster-stricken areas, etc.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

1.Construction and Infrastructure Field

Temporary Buildings and Emergency Facilities

Rapidly construct the foundation or walls of temporary shelters and disaster relief tents. Utilize its rapid solidification property to provide emergency living space in disaster relief.

Ground hardening and fence construction of temporary storage facilities at construction sites, reducing construction costs and time.

Structural Protection and Reinforcement

Waterproof and moisture-proof layers for building foundations, anti-seepage protection for the side walls of basements; it can also be used for the repair and reinforcement of old concrete structures (such as the surface protection of bridge piers and tunnel linings).

2.Field of Environmental and Ecological Engineering

Ecological Slope Protection and Soil and Water Conservation

In slope greening projects, it can serve as the base layer for vegetation growth. It can not only fix the soil to prevent soil erosion but also provide support for plant roots, achieving the combination of engineering protection and ecological restoration.

Sewage Treatment and Environmental Protection Facilities

Laying the anti-seepage layer of sewage treatment tanks and sedimentation tanks to resist the corrosion of chemical substances in sewage and avoid the spread of pollution; it can also be used for the anti-seepage cover layer of landfills.

3.Field of Traffic Engineering

Railway and Highway Drainage Systems

The construction of railway embankment drainage ditches and highway side drainage ditches can replace traditional concrete pouring, shorten the construction period, and at the same time adapt to complex terrains (such as slopes and curves) to ensure smooth drainage.

Subgrade and Slope Protection

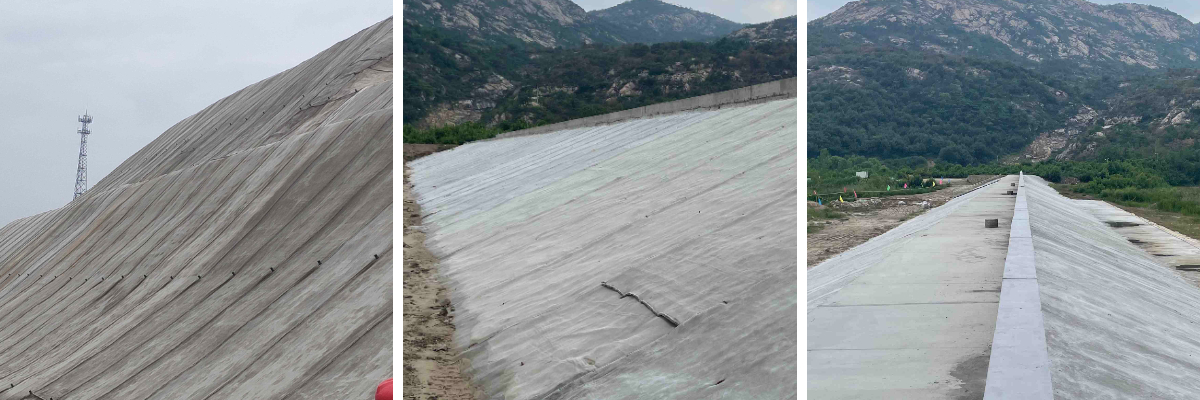

For the protection of highway subgrade slopes and railway cutting slopes, after covering with canvas and solidifying, an overall protective layer is formed to prevent slope collapse and gravel sliding, ensuring traffic safety.

Temporary Roads and Emergency Projects

The rapid paving of temporary construction access roads and emergency rescue and disaster relief roads is especially suitable for remote areas or emergency situations. A load - bearing road surface can be formed without complex construction.

4.Water Conservancy Engineering Field

Construction of Water Channels and Drainage Ditches

For the lining and seepage prevention of agricultural irrigation water channels, it can be quickly laid to form a closed water conveyance channel, reducing water seepage loss and resisting the scouring of water flow at the same time.

For the construction of industrial and civil drainage channels (such as factory wastewater channels, pre-treatment sections of urban sewers), by taking advantage of its waterproof and chemical corrosion-resistant properties, it can prevent sewage from seeping and polluting the soil, and extend the service life of the channels.

River and Dam Protection

For the protection of river slopes and the water-facing side of dams, it can be covered on the slope surface. With the strength after fiber reinforcement and concrete hardening, it can resist the impact of water flow and soil erosion, especially suitable for riverbanks or reservoir dams with serious soil erosion.

For the rapid construction of temporary flood control dams, in flood emergency scenarios, it can be quickly laid and solidified by watering to form a temporary water-blocking structure.

5.Special Engineering and Emergency Scenarios

Military and Defense Engineering

Rapid construction of temporary military fortifications (such as bunkers and trenches), leveraging its portability and rapid solidification characteristics to meet the needs of field combat environments.

Geological Disaster Prevention and Control

Emergency protection in landslide and debris flow areas, forming a temporary blocking structure by covering with canvas to gain time for treatment; protection of mine slopes to reduce the risk of ore sliding.

The core advantages of 3D fiber matrix ditch liner lie in high construction efficiency (no large equipment is required, and it can be operated manually), strong environmental adaptability (weather-resistant, corrosion-resistant, and impact-resistant), and low material consumption (95% less than traditional concrete). It is especially suitable for projects in remote areas, emergency projects, or complex terrains. With the development of technology, its application scenarios are constantly expanding. For example, in the fields of new energy projects (slope protection of photovoltaic power plants) and marine projects (offshore dikes), attempts are gradually being made to use it.