Geosynthetic Cement Composite Mat

1. Efficient and time-saving: 10 times faster than traditional concrete construction, suitable for emergency projects.

2. Strong adaptability: It can adapt to complex terrains such as slopes and ditches.

3. Low cost: Save labor, equipment, and maintenance costs.

4. Durability: The compressive strength can reach over 20 MPa, and the service life is comparable to traditional concrete.

Product Introduction:

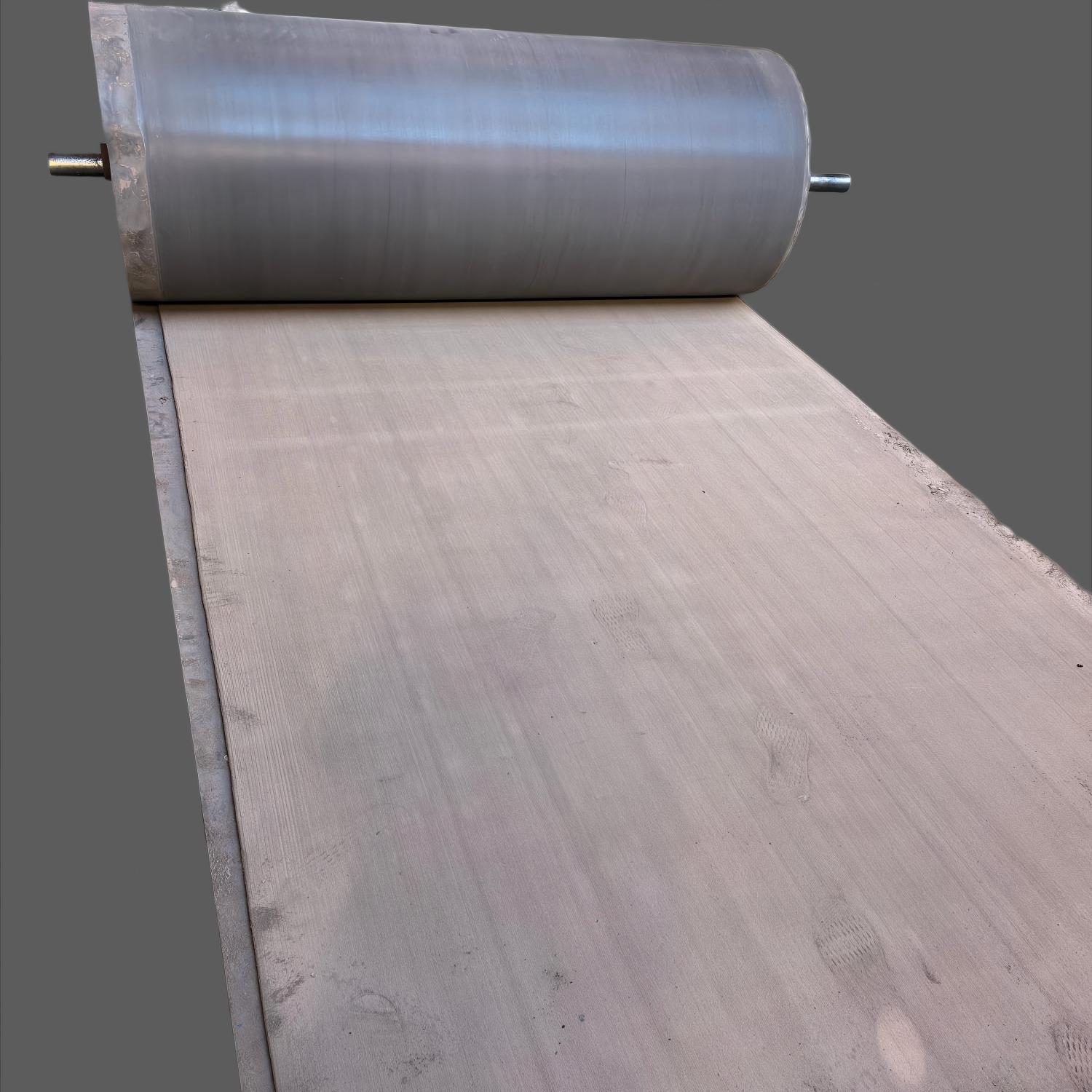

Geosynthetic Cement Composite Mat is a flexible composite material that embeds dry mixed cement powder into a three-dimensional fiber matrix. Its core structure includes:

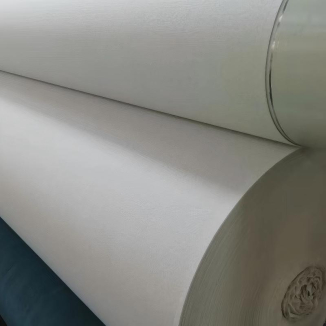

Upper layer: Waterproof polyethylene film to prevent moisture infiltration;

Middle layer: three-dimensional fiber skeleton (such as polyester fiber), providing flexibility and tensile strength;

Lower layer: impermeable layer, enhancing resistance to chemical erosion.

When in use, the cement hydration reaction is activated by watering, and after hardening, a thin layer of concrete structure with a thickness of only 5-10mm is formed, which has the characteristics of waterproofing, fireproofing, durability, etc.

Core Features

1. Flexibility and plasticity

When not hardened, it can be curled and cut like fabric, adapting to complex terrains such as ditches and curved slopes;

After hardening, a high-strength concrete layer is formed, with a compressive strength of 20-40MPa (close to traditional concrete).

2. Rapid curing

After watering, it initially hardens within 1-2 hours and reaches the design strength within 24 hours, shortening the construction period by more than 60% compared to traditional concrete.

3. Multi functional integration

Waterproof: Polyethylene film and anti-seepage layer form a dual protection, with a permeability coefficient of ≤ 1 × 10 ⁻⁸ cm/s;

Fire prevention: extremely low smoke and toxic gas emissions during combustion;

Corrosion resistance: acid and alkali resistant, UV resistant, suitable for chemical polluted environments.

4. Lightweight design

The unit area weight is only 5-15kg/m ² (traditional concrete is about 2400kg/m ³), reducing transportation and construction costs.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

1. Water conservancy engineering: can be used for lining of rivers, reservoirs, canals, etc., such as strengthening existing concrete structures to avoid degradation, prevent soil erosion and water pollution.

2. Transportation Engineering: Suitable for slope protection and roadbed reinforcement of highways and railways, as well as related parts of bridges, subways, and other engineering projects, which can improve the bearing capacity and stability of road surfaces.

3. In the agricultural field, it can be used for waterproofing and anti-seepage in fish ponds, livestock breeding sites, etc., to ensure stable water sources for aquaculture, and can also be used for laying agricultural irrigation channels.

4. Environmental engineering: can be applied to mine greening, landfill, sewage treatment plants, etc., playing a role in preventing soil erosion, anti-seepage, etc.

5. In the military industry, it can be used for tents, flood control and emergency rescue, soft ground foundation, etc. For example, it can be quickly laid for dam reinforcement in flood control and emergency rescue.

Cement blankets have shown significant advantages in scenarios where traditional concrete is difficult to apply by simplifying the construction process, and are known as the "rollable concrete revolution".