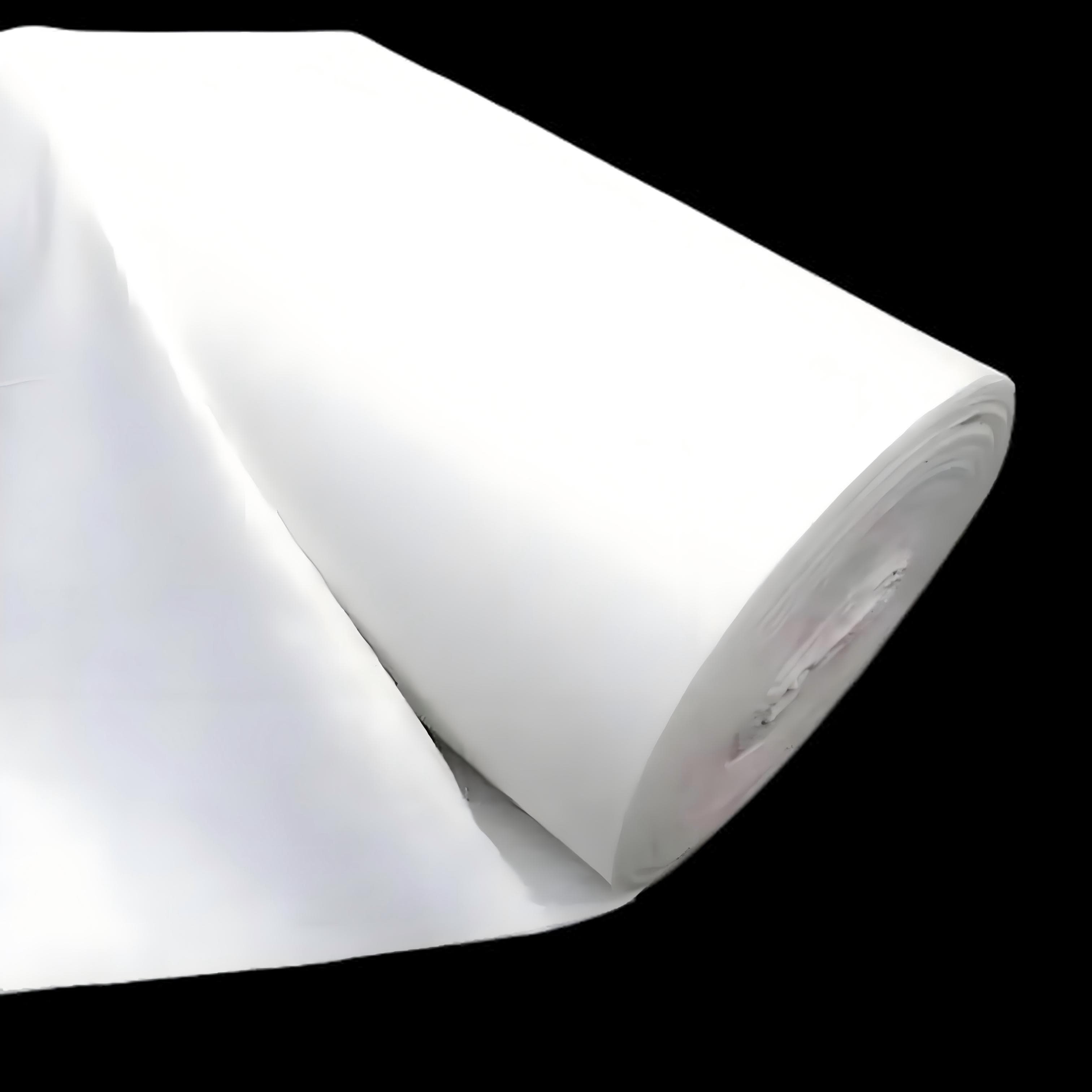

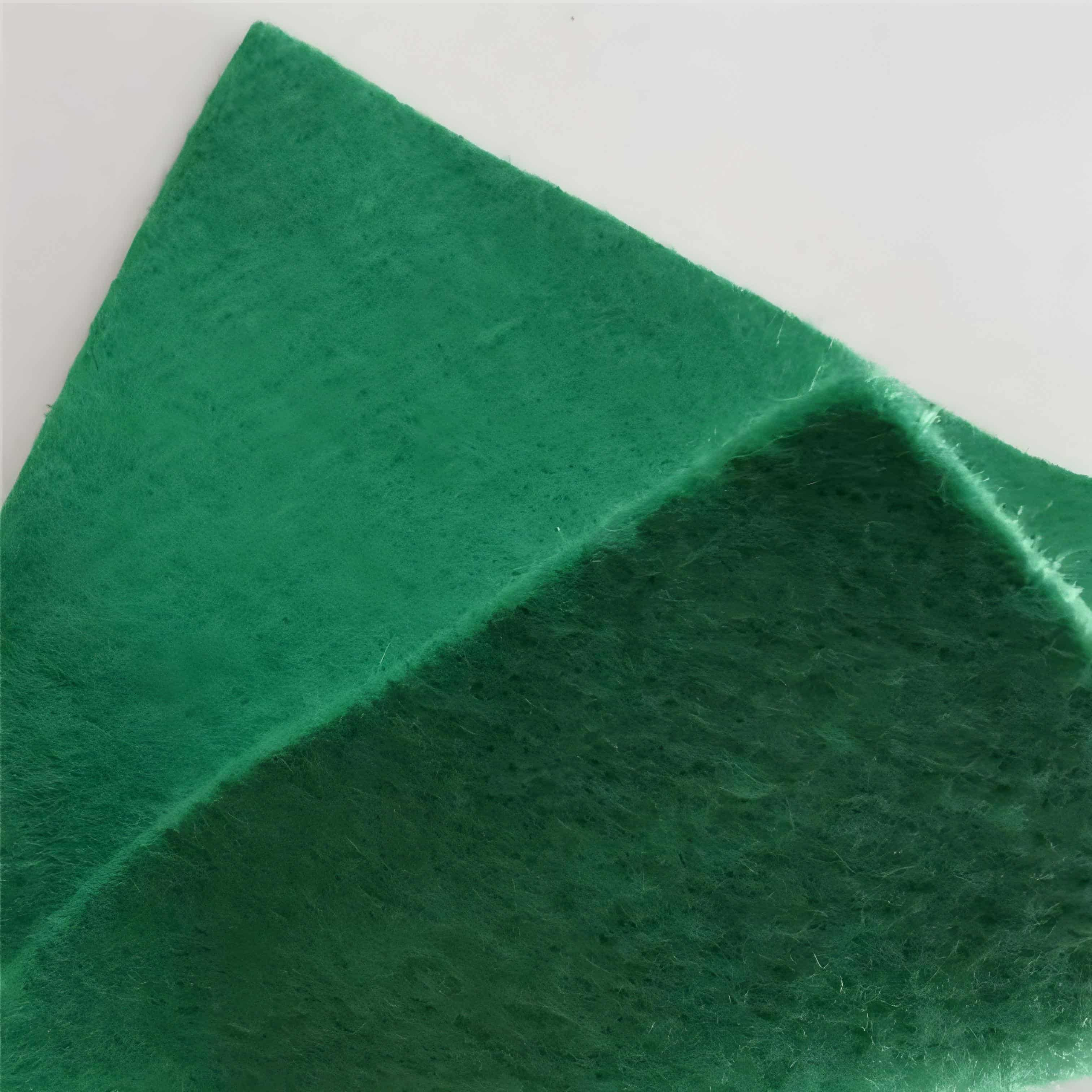

Geotextile Blankets

1. High strength and toughness: Using high-quality materials such as plastic fibers, geotextiles can maintain excellent strength and elongation performance in both dry and humid environments, with high tensile strength, effectively enhancing the tensile strength and deformation resistance of soil, and stabilizing building structures.

2. Corrosion resistance: With excellent chemical stability, it can withstand corrosion for a long time in soil and water environments with different pH values, resist erosion from acidic and alkaline substances, and impurities carried by floods.

3. Excellent permeability: There are gaps between the fibers, and the permeability is good. It can construct drainage channels inside the soil, timely discharge excess liquids and gases, and effectively intercept soil particles, fine sand, etc. to prevent problems such as "pipe surge" and "soil flow", ensuring the stability of water and soil engineering.

4. Easy construction: The material is lightweight, soft, and easy to transport and lay, which can greatly improve construction efficiency, save labor and material costs, and can also be flexibly cut and spliced according to project needs.

Products Introduction:

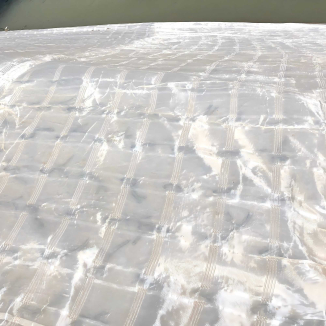

Geotextile Blankets are permeable geosynthetic materials made from high molecular weight polymers such as polypropylene and polyester through processes such as needle punching, weaving, and hot rolling. It is not a traditional "fabric", but a functional material designed specifically for scenarios such as geotechnical engineering and hydraulic engineering. Its core function is to solve problems such as reinforcement, drainage, isolation, and protection in engineering through its own physical properties and structural characteristics. It is one of the indispensable key materials in modern civil engineering.

Product Features:

1. High strength and toughness, stable structure

Made of high-quality polymer fibers, it can maintain stable mechanical properties in different environments such as dry and humid. The tensile strength can reach several times that of ordinary fabrics, and can withstand the tensile force generated by soil settlement, water flow impact, etc., effectively enhancing the deformation resistance of soil, reducing the risk of cracks and collapses, and providing long-term support for engineering structures.

2. Corrosion resistant, long-lasting and durable

The material itself has excellent chemical stability and can withstand erosion from complex environments such as acidic and alkaline soils, industrial wastewater, and groundwater. Even under extreme conditions such as long-term immersion, high temperature, and low temperature, the performance is not easily degraded, and the service life can reach decades, greatly reducing the maintenance cost in the later stage of the project.

3. Permeable and breathable, water and soil complement each other

The porous structure between fibers combines the dual functions of "permeability" and "filtration": on the one hand, it can quickly discharge accumulated water and gas in the soil, avoiding structural damage caused by pressure accumulation; On the other hand, it can intercept soil particles, fine sand, etc., prevent soil erosion, and fundamentally solve engineering hazards such as "pipe surge" and "soil flow".

4. Flexible and convenient, with strong adaptability

The texture is light and soft, usually weighing less than 1 kilogram per square meter, and does not require large equipment for transportation and laying. At the same time, it can be flexibly cut and spliced according to engineering requirements, adapting to irregular terrains such as slopes, roadbeds, and dams, significantly improving construction efficiency.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering: used in projects such as dams, channels, and reservoirs to reinforce dam slopes, filter water impurities, and accelerate drainage to prevent dam collapse due to water infiltration.

2. Road construction: Laying under the roadbed, it can isolate different soil layers (such as sand and clay), avoid road settlement caused by soil mixing, and extend the service life of the road.

3. Environmental protection engineering: used as an auxiliary material for anti-seepage layer in landfills to filter pollutants in leachate; Used in river dredging projects to fix the riverbed and prevent further sedimentation of sediment.

4. Municipal and agricultural: The foundation reinforcement of urban green belts and parking lots, as well as the anti-seepage and drainage of irrigation channels in farmland, can all play a role in stabilizing the structure and saving water.

Geotextile Blankets, with its core advantages of high strength, corrosion resistance, permeability, and convenience, has achieved an upgrade to traditional civil engineering materials through material innovation and functional integration. It can not only solve basic problems such as reinforcement, drainage, and protection, but also adapt to complex environments and diverse scenarios, providing efficient and sustainable technical support for various projects from water conservancy and roads to environmental protection and agriculture. Choosing Geotextile Blankets geotextile is not only a guarantee of engineering quality, but also an optimization of long-term economic benefits. It is an ideal choice for modern engineering construction that combines practicality and reliability.