Geotextile Bag

1.Efficient Construction & Cost Savings

Direct pumping of mortar/concrete eliminates formwork, improving efficiency by 3-5x.Deployable in challenging terrains (underwater, steep slopes, etc.).

2.High Erosion Resistance

Woven geotextile with tensile strength ≥50 kN/m, withstands water flow ≥3 m/s.

3.Permeability & Soil Retention

Effective drainage (AOS ≤0.1mm) while preventing filler loss.

4.Durability

UV-resistant, chemical-tolerant (pH 2-12), service life >30 years.

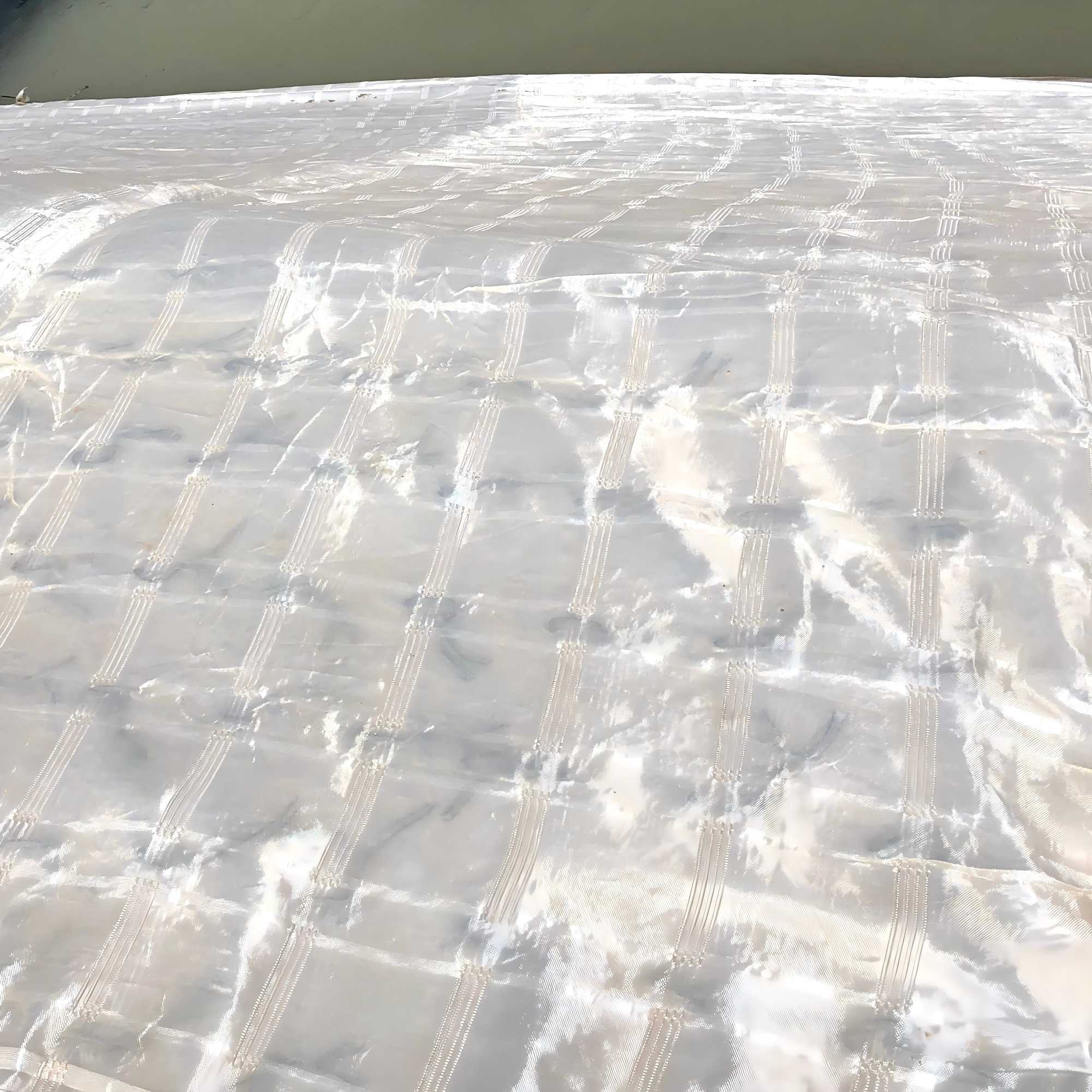

Product Introduction:

Geotextile Bag is double-layer continuous bagged materials woven from industrial filaments such as polyester and polypropylene, and sewn and processed. They are filled with concrete or mortar, which solidifies to form plate-shaped protective blocks. The geotextile formwork bag serves as a flexible formwork, and the surface layer of the formwork fabric protects the concrete or mortar blocks.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

1.River and Coastal Engineering:

Riverbank slope protection, seawall wave prevention, reservoir dam slope

2.Slope Protection:

Railway and highway slope, mine slope management

3.Ecological Restoration Engineering:

Stone desertification control, tidal flat reclamation, constructed wetland

4.Emergency Rescue Engineering:

Embankment pipe burst blocking, flood control and rescue

5.Municipal and Water Conservancy Engineering:

Drainage channel lining, reservoir slope