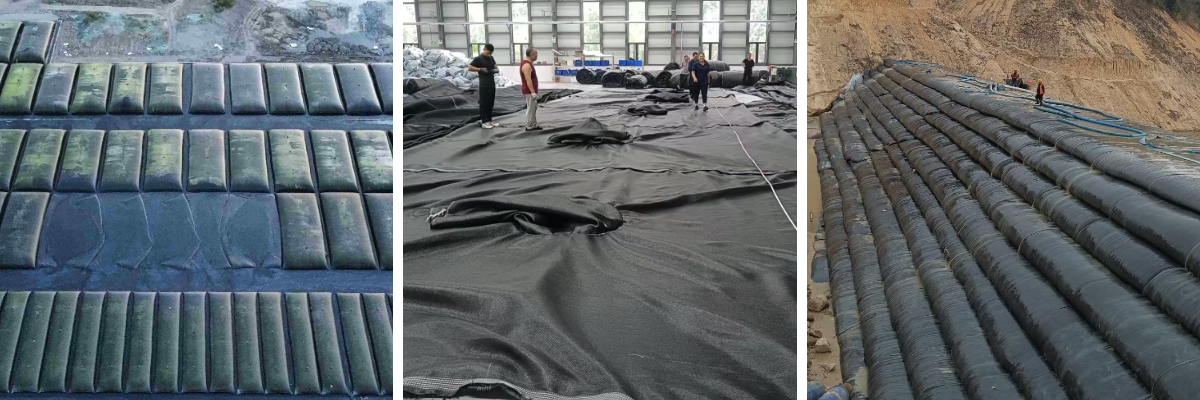

High - Strength Geotextile Tube Bags

High dewatering efficiency: The moisture content of the slurry can be reduced from 90% to less than 50%, and the speed is 3 - 5 times that of the sedimentation tank;

Convenient construction: Prefabricated production, on - site filling is sufficient, the construction period is shortened by more than 50%, and it is suitable for complex terrains (such as tidal flats and swamps).

Low cost: The material and logistics costs are 30%-50% lower than those of the concrete solution, and the maintenance cost is low;

Environmentally friendly: Recyclable materials account for 90%, reducing the ecological damage of quarrying and supporting vegetation/ecological restoration.

Product Introduction:

High - Strength Geotextile Tube Bags demonstrate multi - dimensional advantages in fields such as water conservancy, environmental protection, and civil engineering.It is woven from synthetic fibers such as polypropylene (PP) or polyester (PET). The tensile strength can reach 10 - 300 kN/m. It is resistant to acids and alkalis, and can withstand ultraviolet aging. The service life can be as long as 10 - 20 years (depending on the environment), and it is suitable for harsh working conditions (such as seawater erosion and contact with industrial wastewater).

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1.Industrial and Municipal Sectors

Sewage Treatment Plants: Sludge reduction treatment.

Mine Restoration: Neutralization and solidification of acidic mine pit slurries.

Infrastructure Projects: Resource utilization of shield slurry and pile foundation surplus slurry.

2.Water Conservancy and Environmental Protection Projects

River/Lake Dredging: Sludge dewatering and harmless disposal.

Tailings Pond Treatment: Tailings sand dewatering and solidification to prevent heavy metal leakage.

Shoreline Restoration: Dredged sediment solidification to construct the substrate for artificial wetlands.

3.Agriculture and Ecology

Purification of Farmland Drainage Water: Interception of eutrophic suspended solids.

Saline - Alkali Land Improvement: Reducing soil salinity through mud desalination.

4.Water Conservancy and Environmental Protection Projects

River/Lake Dredging: Sludge dewatering and harmless disposal.

Tailings Pond Treatment: Tailings sand dewatering and solidification to prevent heavy metal leakage.

Shoreline Restoration: Dredged sediment solidification to construct the substrate for artificial wetlands.

5.Agriculture and Ecology

Purification of Farmland Drainage Water: Interception of eutrophic suspended solids.

Saline - Alkali Land Improvement: Reducing soil salinity through mud desalination.

High - Strength Geotextile Tube Bags, as a flexible, cost - effective, and ecological engineering material, have significant advantages in fields such as soil and water conservation, coastal protection, and environmental governance. They are particularly suitable for emergency projects, soft foundation treatment, and waste resource utilization scenarios. Their durability depends on the anti - aging performance of the material and construction quality. Under normal circumstances, their service life is 5 - 15 years, and it can be further extended through material modification (such as anti - UV and acid - alkali - resistant formulations) and protective measures. In the future, with the increasing demand for ecological and environmental protection, the application of geotextile tube bags in green infrastructure construction will become more extensive.