Geobag

1.Good Integrity:

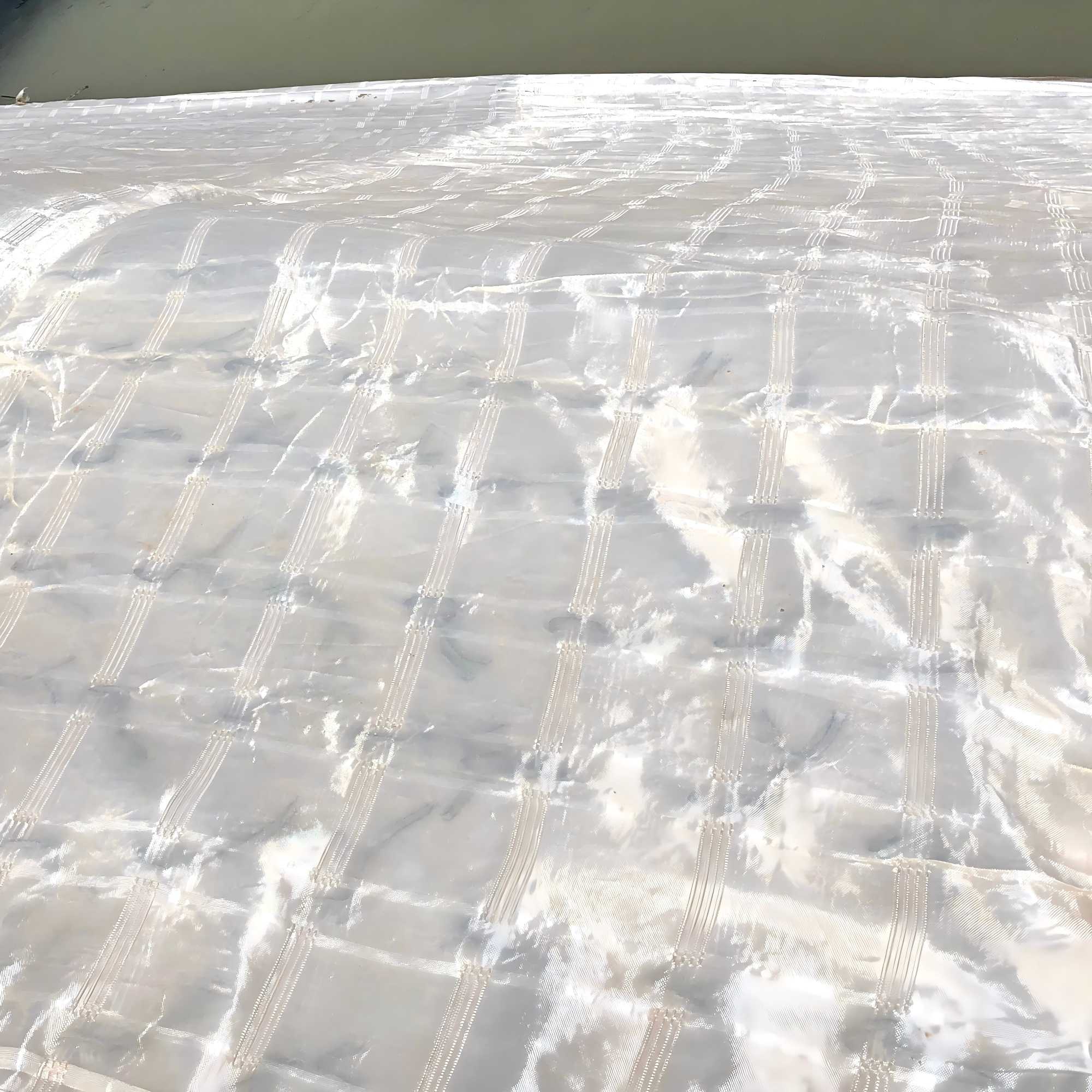

After the concrete or cement mortar in the geotextile bag solidifies, it forms an integral plate-like structure with high strength and stability, preventing slope collapse and soil erosion.

2.Good Permeability:

Excess water can seep out through the fabric pores after concrete or cement mortar is poured, accelerating the solidification speed of concrete and increasing its compressive strength.

3.Strong Corrosion Resistance:

It has excellent resistance to acid, alkali, salt spray, and other corrosive factors, ensuring a long service life.

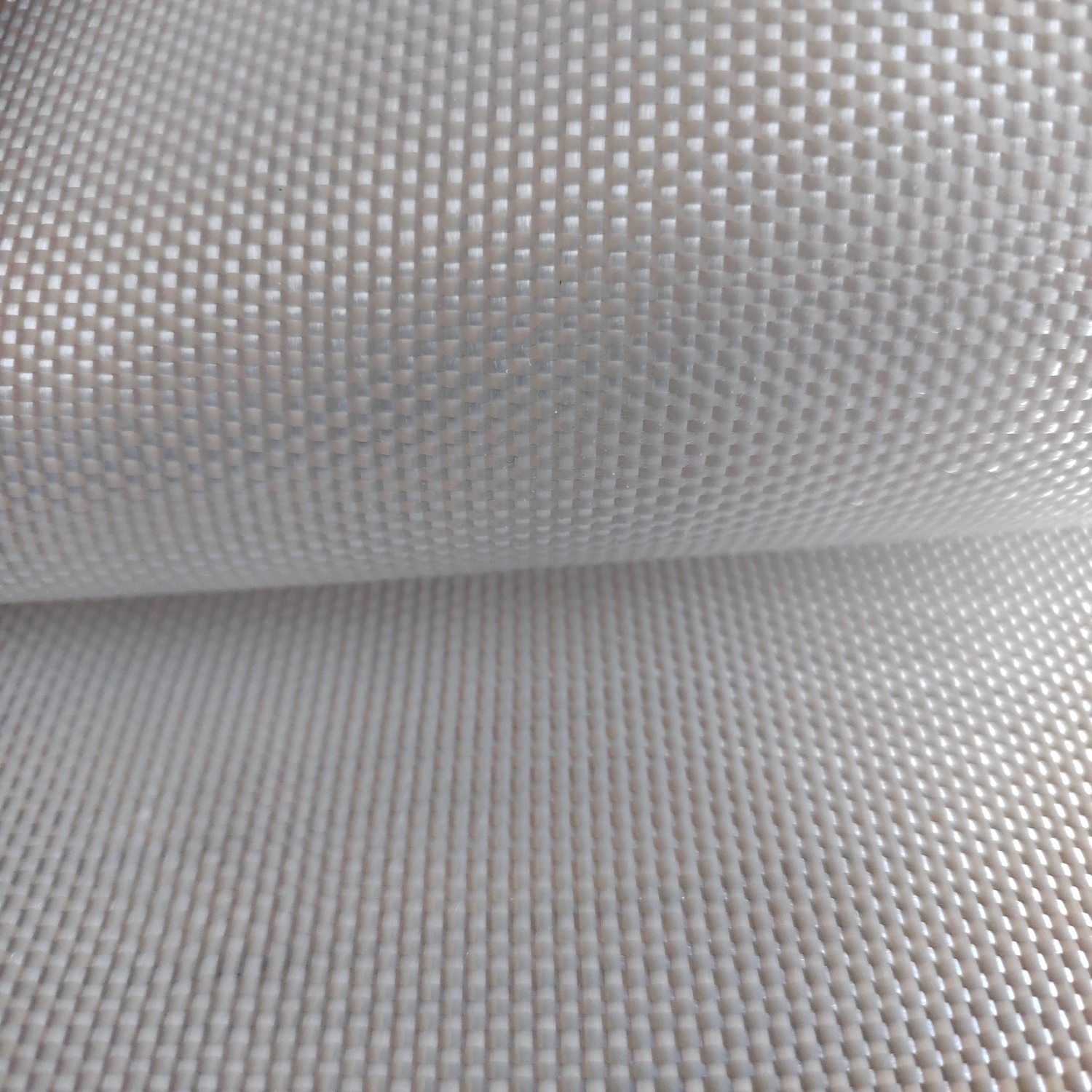

Product Introduction:

Geobag is large-area continuous bag-shaped materials made of upper and lower layers of geotextiles. The bags are filled with concrete or cement mortar, which solidifies to form an integral concrete slab, and can be used for slope protection and other projects.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

1.Hydraulic Engineering: Widely applied in protective projects such as dike slope protection, revetment, ports, and docks for rivers, lakes, and seas. It can effectively prevent the scouring of water flow on embankments and protect the safety of dikes.

2.Transportation Engineering: Used for slope protection of highway and railway subgrades to enhance subgrade stability, prevent slope collapse and soil erosion, and extend the service life of highways and railways.

3.Environmental Protection Engineering: Plays a role in landfill covering, tailings pond slope protection, etc., to prevent landfill leachate and tailings from polluting soil and groundwater.

4.Coastal Protection Engineering: Applied to coastal protection to resist wave erosion, maintain coastline stability, and simultaneously beautify the coastal environment and improve landscape effects.

Geobag, as engineering materials that combine flexible construction with rigid protection, have irreplaceable advantages in fields such as soil and water protection, slope stability, and ecological restoration, and are particularly suitable for complex terrains, underwater environments, and ecological projects. Their durability depends on the anti - aging performance of the materials and the strength of the concrete (with a service life of 20 - 30 years under normal circumstances), and the lifespan can be further extended through anti - UV fabrics and high - performance concrete formulations. In the future, with the growth of the demand for green infrastructure, the applications of geotextile bags in sponge cities and waterfront ecological restoration will become more diversified.