Fabric Formwork Bag

1.Strong Terrain Adaptability:

Can be constructed on 1:1.5 steep slopes, underwater, and irregular base surfaces, with fast laying speed.

2.High erosion resistance

Withstands flow velocities ≥3 m/s and wave action (≥5 m wave height)

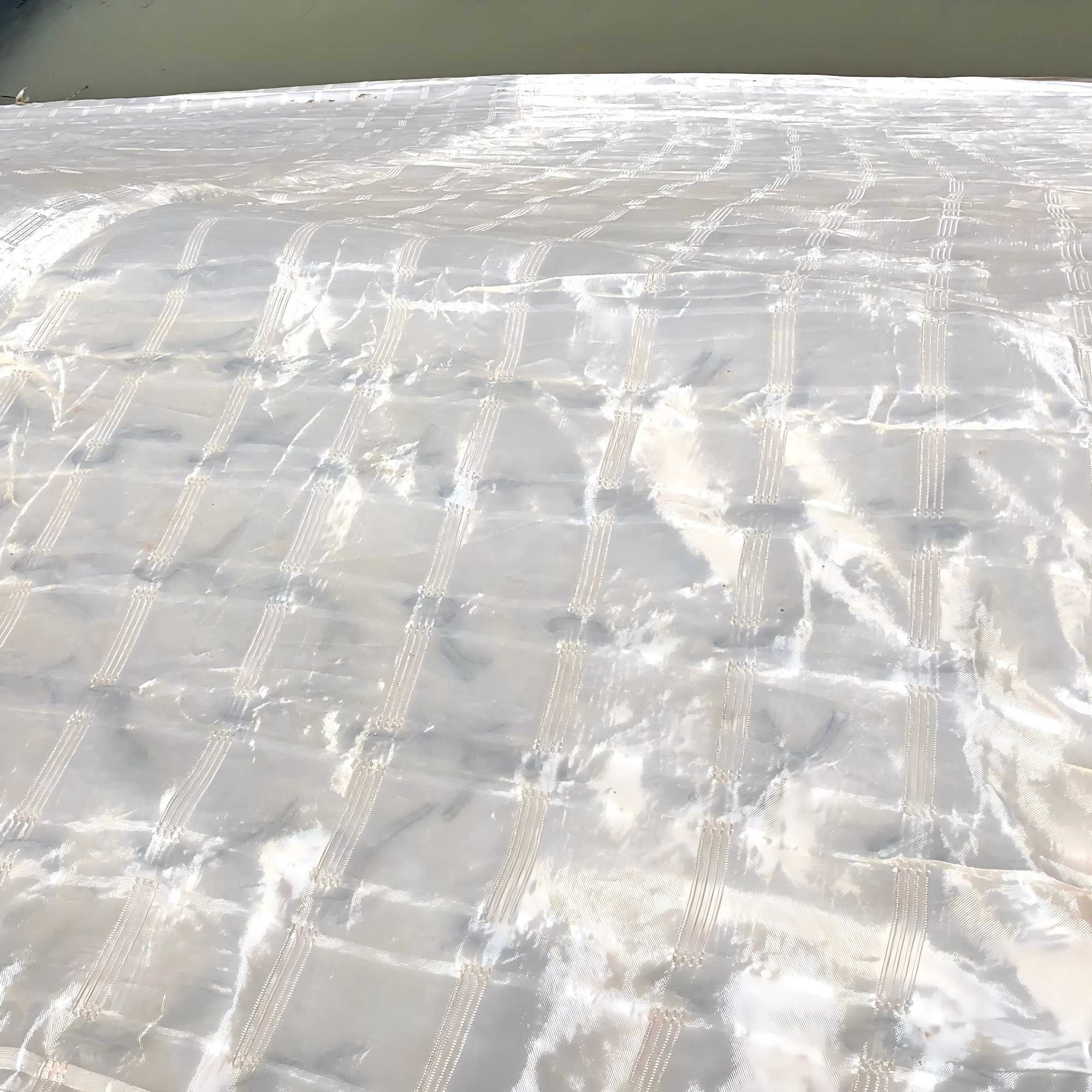

3.Flexible-to-rigid transition

Conforms to ground irregularities before hardening into a structural slab (15–30 MPa strength)

4.Long-term durability

UV-resistant, chemical-tolerant (pH 2–12), service life >30 years

Product Introduction:

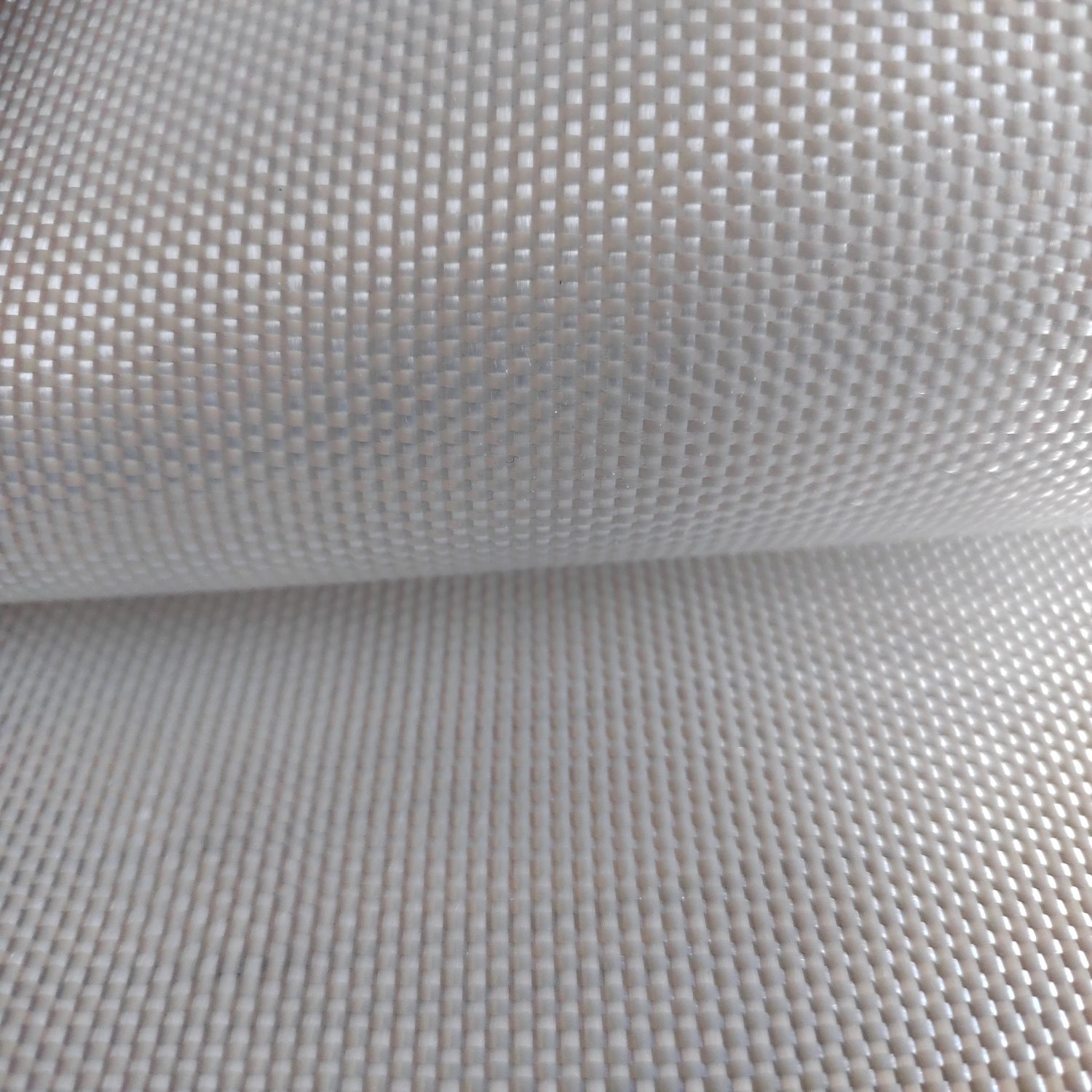

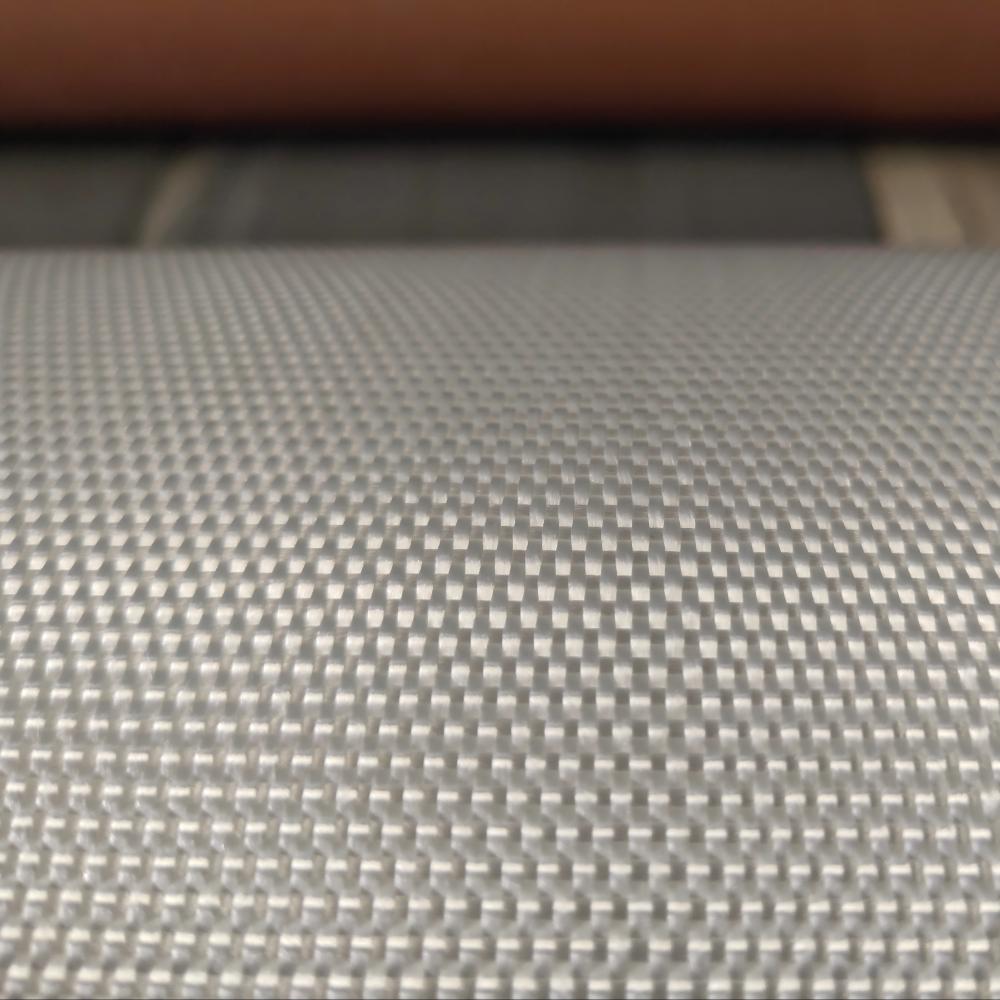

Fabric Formwork Bag is an advanced composite material system consisting of high-strength synthetic fibers (polyester/polypropylene) woven into a double-layered flexible container through specialized textile engineering. When filled with concrete or mortar, it forms a rigid protective structure for erosion control and slope stabilization.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

1.Water Conservancy Projects:

Riverbank slope protection;Levee reinforcement;Reservoir drawdown zone stabilization

2. Coastal & Harbor Engineering:

Breakwater armor layer;Artificial island cofferdams;Wharf bulkhead protection

3. Transportation Infrastructure

Railway/highway embankment slopes;Tunnel portal protection;Bridge pier encasement

4. Mining & Environmental Remediation

Tailings dam slope stabilization;Mining pit rehabilitation;Contaminated site capping

5. Emergency Response

Breach closure;Landslide emergency stabilization;Freeze-thaw damage prevention

6. Ecological Engineering

Eco-revetments;Wetland construction;Coral reef substrate foundation