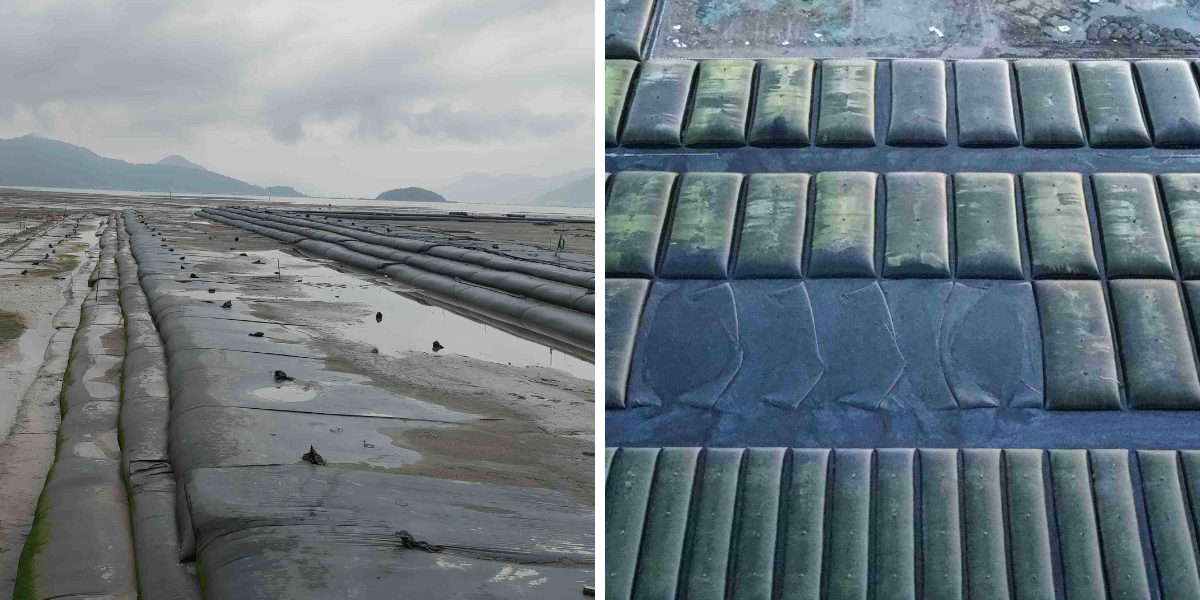

Sediment Control Bags

1. Construction efficiency:Fast filling speed, high degree of mechanization, reducing manual labor requirements

2. Material cost:Geotextile materials have low cost and can be sourced locally, reducing transportation costs

3. Space occupation:High volume compression rate after dehydration, saving storage space

4. Environmental friendliness:The dehydration process is controllable, and the leaked water can be collected and treated for reuse, avoiding soil/water pollution

Product Introduction:

Sediment Control Bags are large tubular bag made of high-strength geotextile (usually polypropylene or polyester material).

The core working principle is:

Fill the bags with mud (such as silt, sludge, tailings, etc.) through pumping equipment. Geotextiles act as' filters', allowing moisture to seep out of the fabric's tiny pores under pressure, while effectively trapping and sealing solid particles inside the bag. By layer by layer filling and drainage consolidation, a sturdy and stable soil structure or dehydrated solid material is ultimately formed.

Simply put, it is like a huge, leaking sandbag specifically designed to handle fluid materials with high moisture content.

Feature

1. Material characteristics:

High tensile strength: able to withstand the enormous pumping pressure of internal mud and the load of external stacking.

Directional filtration: The pore size is carefully designed to ensure that water can be smoothly discharged while the target solid particles are effectively retained.

Anti clogging property: The special weaving process prevents fine particles from clogging the pores of the fabric, maintaining long-term drainage capacity.

2. Structural characteristics:

Flexible structure: It can adapt to uneven settlement of the foundation and is not prone to cracking like rigid structures.

Integrity: Multiple geotextile bags can be stacked and connected to form larger and more complex composite structures, such as breakwaters, cofferdams, etc.

3. Process characteristics:

Staged filling: It is necessary to use a layered filling method. After the lower layer of mud is preliminarily drained and consolidated, the upper layer can be filled to ensure structural stability and dewatering effect.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Water conservancy engineering

River/lake dredging solid waste treatment: Inject the high moisture content mud (moisture content of 90% -95%) generated by dredging into geotextile bags, dehydrate and form dry soil blocks to prevent mud from being discharged indiscriminately and polluting water bodies. Dry soil can be used for embankment thickening or land reclamation.

Flood control embankment/flood emergency rescue: In emergency situations, quickly fill the geotextile bags to form a temporary water retaining embankment. Its flexible structure can adapt to water flow impact and has stronger anti erosion ability than traditional sandbags. Moreover, the construction speed is fast (dozens of cubic meters of filling can be completed in 1 hour).

2. Marine and Coastal Engineering

Artificial island construction and land reclamation: In shallow sea areas, geotextile bags are used to fill sea sand to form embankments, replacing traditional stone throwing embankments, reducing material costs (sea sand can be sourced locally), and minimizing damage to marine ecology; The embankment formed by the consolidation of the pipe bag has strong stability and can resist wind and wave erosion.

Coastal protection and beach maintenance: In eroded coasts, offshore submerged embankments or revetments are constructed using geotextile bags to reduce the impact of waves, while slowly releasing the sediment consolidated in the bags onto the beach to achieve beach maintenance.

3. Environmental Engineering

Harmless disposal of sludge: treating sludge generated from municipal sewage treatment plants and industrial wastewater treatment, dehydrating it through geotextile bags (reducing the moisture content to below 60%), reducing the volume of sludge (reducing the volume to 1/3-1/5 of the original volume), and reducing subsequent landfill or incineration costs; Part of the industrial sludge (such as mining tailings) can be consolidated for resource utilization (such as brick making and roadbed filling).

Landfill anti-seepage and coverage: Fill clay or anti-seepage materials with geotextile bags at the bottom of the landfill to form an auxiliary anti-seepage layer, enhancing the anti-seepage effect of the landfill; After the landfill is completed, cover the garbage with geotextile bags instead of traditional clay covering to reduce rainwater infiltration and landfill gas leakage.

4. Transportation and Municipal Engineering

Soft soil foundation treatment: In highway and railway construction, for soft soil foundation areas, geotextile bags are filled with sand and gravel or solidified soil to form a "pipe bag composite foundation", which improves the bearing capacity of the foundation and reduces roadbed settlement (settlement can be reduced by 30% -50%).

Roadbed and slope protection: In mountainous highway slopes, local soil and rock materials are filled with geotextile bags to construct flexible protective slopes, replacing rigid concrete slope protection. This can prevent slope collapse and integrate with the natural environment (vegetation can be planted on the surface of the bags).

5. Mining Engineering

Tailings pond management and reuse: Inject mine tailings (such as metal ore and coal mine tailings) into geotextile bags, dehydrate and solidify them to form a stable tailings dam, and avoid the risk of tailings dam collapse; The consolidated tailings can be used for mine reclamation or as building aggregates to achieve tailings resource utilization.

Geotube bag is a comprehensive technological innovation that integrates materials science, geotechnical engineering, and environmental engineering. With its outstanding advantages of economy, efficiency, environmental protection, and flexibility, it provides a new way of thinking for solving a large number of problems in sludge and sludge treatment and constructing underwater structures. It is known as the "soft container revolution" and plays an increasingly important role in modern engineering construction.