Geotextile Filter Bag

1. Low cost, economically efficient:Utilizing on-site sediment hydraulic filling eliminates the need for purchasing materials such as stone and concrete, as well as transportation costs, resulting in fast construction speed and low overall cost.

2. Energy conservation and environmental protection, turning waste into treasure:It can effectively handle and resource utilize the waste mud generated from dredging and dredging, reduce waste emissions and carbon emissions, and achieve the goal of "treating waste with waste".

3. Flexible construction and strong adaptability:Sizes can be customized according to requirements and can adapt to complex terrains such as soft foundations and underwater environments. Multiple stable structures can be formed through stacking.

4. Quick dehydration, stable and long-lasting:Through the filtering effect of geotextiles, rapid solid-liquid separation is achieved, accelerating the progress of the project. The flexible structure formed has good stability and can adapt to foundation settlement.

Product Introduction:

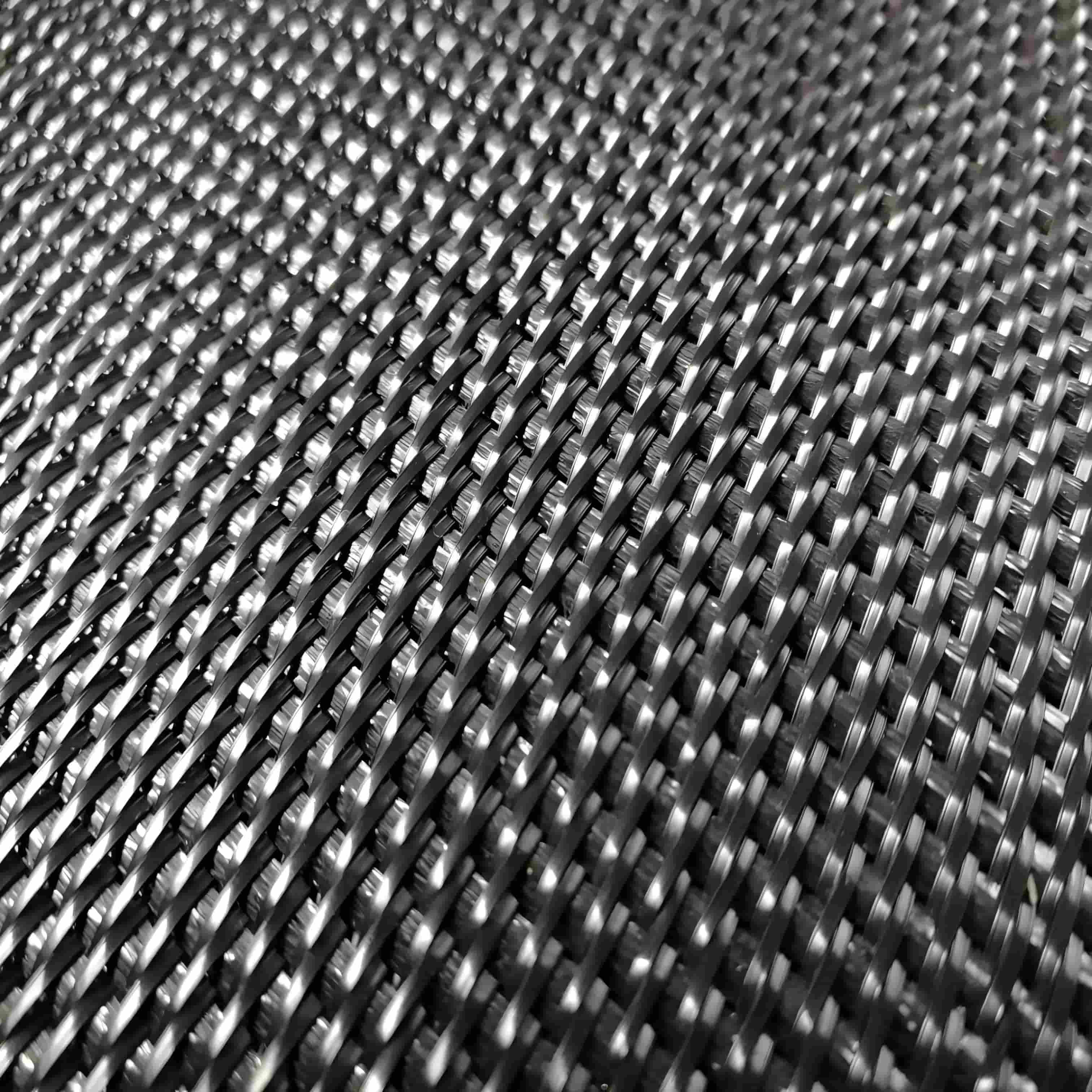

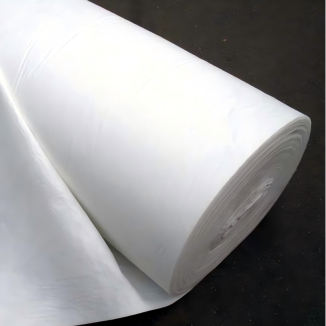

Geotextile Filter Bag is a "flexible geotextile container", and its core function is to utilize the filtration, permeability, and bearing characteristics of geotextile materials to achieve integrated treatment of fluid media through "collection consolidation molding". Unlike traditional rigid structures such as concrete dams and gabion nets, it combines "material flexibility+medium consolidation" to achieve adaptability and stability. It can be customized according to engineering requirements in terms of diameter (usually 0.5-6m), length (usually 10-100m), and bearing strength.

Its working principle is divided into three steps:

Filling stage: Inject the well proportioned mud, sand slurry, sludge and other media into the pipe bag under high pressure through the pipeline. The geotextile allows moisture to seep out while retaining solid particles;

Consolidation stage: As water is continuously discharged, the medium inside the bag gradually dehydrates and solidifies, forming a dense solid core;

Forming stage: The solidified pipe bags can be used independently as a single unit or stacked/spliced in multiple ways to form a structure that meets engineering requirements (such as dams, foundations, landfill cover layers, etc.).

Key Features

The performance of geotextile bags is determined by both the "characteristics of the geotextile material" and the "characteristics of the core after consolidation", and the core characteristics can be summarized into the following four points:

1. The material has strong weather resistance

The geotextile used for making pipe bags is treated with UV resistance, acid and alkali resistance, and biological corrosion resistance. It can be used for a long time in harsh environments such as seawater immersion, high temperature exposure, and saline alkali land. The service life can usually reach 20-50 years, which is much better than ordinary fabrics or plastic materials.

2. Filtering and soil conservation balance

The aperture of geotextile is precisely designed (usually 0.05-0.2mm): it can quickly remove moisture from the filling medium (improve consolidation efficiency), and completely intercept solid particles (avoid medium loss and ensure core density).

3. Controllable bearing strength

The load-bearing capacity of the tube bag can be adjusted in two ways:

Material strength: Select geotextiles with different fracture strengths (commonly 10-50kN/m) to meet the tensile and tear resistance requirements of different projects;

Core ratio: By adjusting the particle size distribution of the filling medium (such as adding curing agents such as cement and lime), the compressive strength of the solidified core can be increased to 0.5-2MPa, comparable to small concrete structures.

4. High construction flexibility

Form customization: It can be made into tube bags with different cross-sections such as circular, elliptical, square, etc. according to engineering requirements;

Convenient splicing: Multiple tube bags can be connected by hot melt welding or high-strength stitching to form a continuous large structure (such as a breakwater several hundred meters long);

Later adjustment: If the engineering requirements change, the consolidated pipe bags can be disassembled, transported, and refilled for use (in some scenarios).

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Water conservancy engineering

River/lake dredging and dike consolidation: fill the sludge generated from river dredging into pipe bags, and stack it on the outside of the river embankment after consolidation to form an integrated project of "dredging and dike consolidation" (such as the Taihu Lake Lake and Huaihe River dredging projects in China);

Breakwater/Embankment: In port and bay areas, sand and gravel or solidified silt are filled into pipe bags and stacked into breakwater or revetment structures to resist wave impacts (compared to traditional stone breakwaters, the cost is reduced by more than 40%);

Reservoir anti-seepage reinforcement: Lay pipe bags in the leakage area of the reservoir dam, fill them to form an anti-seepage layer, and reduce the risk of dam leakage.

2. Environmental engineering

Sludge treatment and disposal: Treating sludge generated by municipal sewage treatment plants, printing and dyeing plants, etc., filling the sludge into pipe bags, dehydrating and consolidating it, reducing the volume by 60% -80%, and facilitating subsequent landfilling or resource utilization (such as making green soil);

Landfill Cover: Fill construction waste or solidified soil with pipe bags at the top of the landfill to form a temporary or permanent cover layer, reducing the diffusion of leachate and odorous gases, while preventing rainwater infiltration.

3. Transportation and Municipal Engineering

Subgrade reinforcement: lay pipe bags on soft soil foundation (such as beach coating and marshland), fill sand and gravel or solidified soil as subgrade base, improve the bearing capacity of foundation and avoid subgrade settlement (such as foundation treatment of coastal expressway and airport runway);

Artificial Island/Sea Reclamation: In the sea reclamation area, temporary water retaining structures are formed by filling mud and sand with pipe bags, or directly used as the main structure of the artificial island (compared to traditional land reclamation, the construction period is shortened by 50%).

4. Mining Engineering

Tailings treatment: Fill mine tailings (such as metal ore and coal mine tailings) into pipe bags, consolidate them to form tailings dams or slag barriers, reduce the footprint of tailings ponds, and lower environmental risks caused by tailings leakage (such as tailings treatment projects in mining provinces such as Jiangxi and Yunnan in China);

Backfilling of goaf: The pipe bags are filled and used for backfilling the goaf of the mine to prevent ground collapse and achieve the resource utilization of tailings.

5. Agriculture and ecological restoration

Irrigation renovation of farmland: laying pipe bags on both sides of farmland ditches to form small dams, preventing ditch collapse and reducing soil erosion;

Wetland ecological restoration: Fill lightweight soil and plant seeds with pipe bags, lay them in degraded wetland areas, and provide a foundation for plant growth after consolidation, promoting wetland ecological restoration.

Geotube bag technology, with its outstanding advantages of economy, efficiency, environmental protection, and flexibility, has become an indispensable innovative technology in modern geotechnical and environmental engineering, especially playing an important role in soft foundation treatment, silt disposal, and near water engineering.