Geo Fabric for Roads

1. Stable roadbed: Enhance the overall integrity of the road base, disperse vehicle loads, reduce roadbed deformation, and lower the risk of pavement cracking.

2. Damage resistance and durability: resistant to soil erosion and vehicle rolling, strong anti-aging performance, and extended road service life.

3. Assist in drainage: Allow moisture to permeate and discharge, avoid softening of roadbed water, and maintain the stability of road structure.

4. Efficient construction: Lightweight and easy to lay, simplifying the construction process, saving time and labor costs.

Products Introduction:

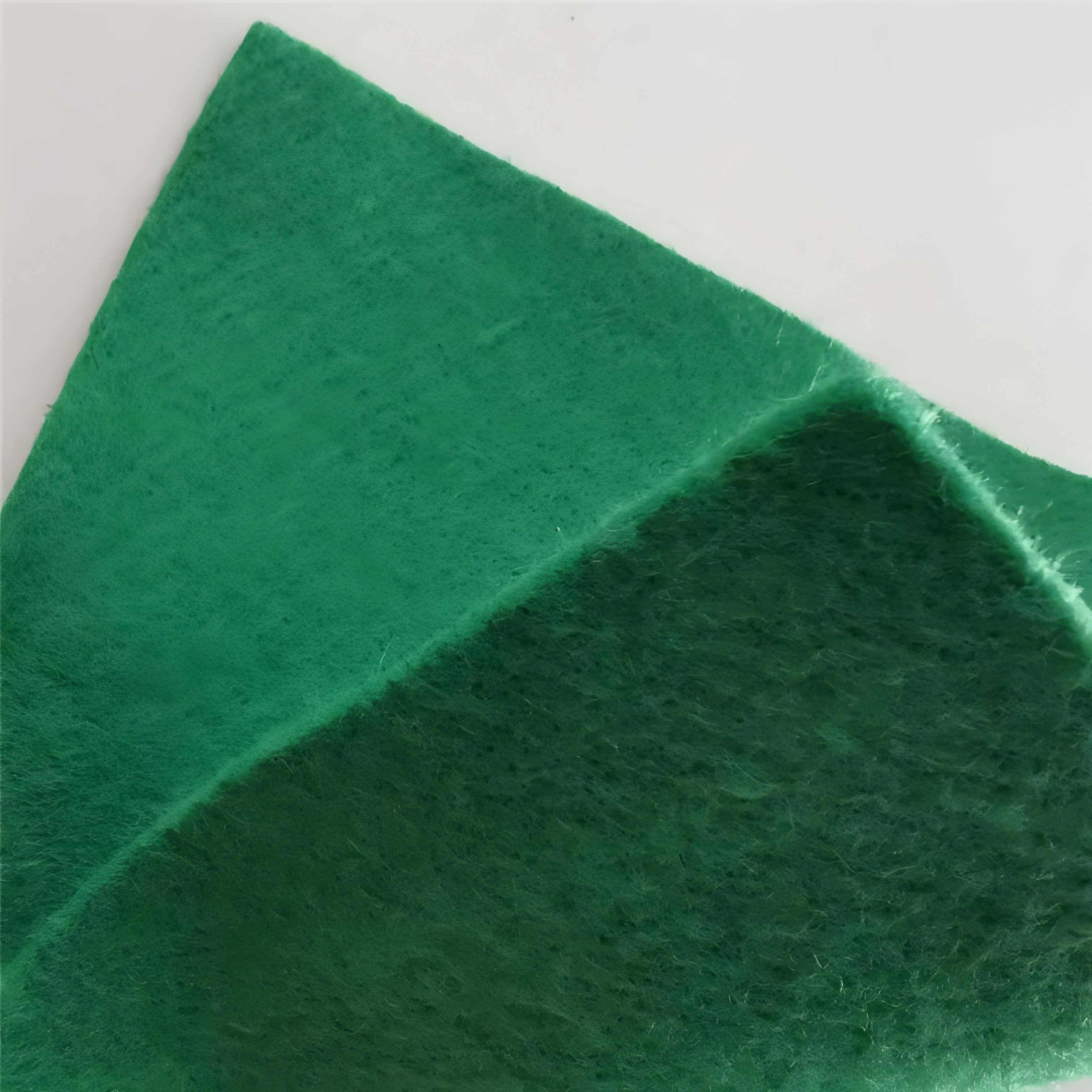

Geo Fabric for Roads is a high-performance geosynthetic material designed specifically for road construction, made from high-quality polymer materials such as polyester or polypropylene woven or non-woven through special processes. As a key auxiliary material in road structures, it can effectively optimize the performance of road base layers, provide solid structural support for various types of roads (from rural roads to high-grade highways), and is an important guarantee for improving quality and extending service life in modern road engineering.

Product Features:

1. Outstanding structural strengthening ability: With excellent tensile strength and extensibility, it can enhance the overall integrity and stability of the road base, evenly distribute vehicle loads to a larger area, reduce deformation caused by excessive local stress on the road surface, and fundamentally reduce the probability of road cracking, collapse and other problems.

2. Strong durability: Made of materials with strong weather resistance, it can withstand acid and alkali erosion in soil, microbial corrosion, and wear caused by long-term vehicle rolling. At the same time, it has excellent resistance to UV aging and can maintain stable performance in various complex environments, greatly extending the service life of the road.

3. Excellent drainage performance: The material has a rich pore structure inside, which allows rainwater and other moisture to quickly penetrate and be discharged from the roadbed, avoiding the accumulation of moisture at the base layer and causing soil softening, maintaining the stability of the road structure, especially in rainy areas or poorly drained sections.

4. Convenient and efficient construction: The material is lightweight, much lighter than traditional reinforcement materials, and has good flexibility, making it easy to cut, transport, and lay. During the construction process, there is no need for complex equipment and technology, which can quickly integrate into the road construction process, effectively shorten the construction period, and reduce labor and equipment costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. High grade highway construction: In road projects with high traffic flow and heavy loads such as highways and national highways, it can be laid between the base and sub base to enhance the overall structural strength, resist the damage caused by long-term rolling of heavy vehicles, and ensure the long-term stable operation of the road.

2. Rural road renovation: In response to poor soil conditions and limited funding in rural areas, the use of this material can improve the bearing capacity of roadbeds, reduce road maintenance frequency, improve rural traffic conditions, and assist in rural infrastructure construction.

3. Urban road maintenance: In the renovation and maintenance of urban roads, laying them on the damaged pavement base can quickly restore the stability of the road structure, extend the service life of the repaired road, and reduce the impact of frequent maintenance on urban traffic.

4. Industrial park roads: Heavy freight vehicles often come and go in industrial parks. This material can effectively disperse vehicle loads, protect the base of park roads, ensure smooth logistics transportation, and reduce maintenance costs of park roads.

Geo Fabric for Roads plays an important role in road construction due to its outstanding structural strengthening ability, excellent durability, good drainage performance, and convenient construction characteristics. It can not only improve the overall quality and stability of roads, effectively reduce the occurrence of various road surface diseases, but also significantly extend the service life of roads and reduce construction and maintenance costs. Whether it is a high load traffic artery or a small rural road, reliable structural support can be obtained through the use of this product, making it an efficient and practical high-quality material in road engineering.