Riprap Geotextile Fabric

1. Enhance foundation: Improve soil bearing capacity and prevent uneven settlement.

2. Function of isolation layer: prevent mixing of different soil layers (such as roadbed and soft soil).

3. Drainage and water diversion: Accelerate the discharge of water and reduce the damage of water pressure to the structure.

4. Protective function: prevent soil erosion, used for slope protection, river and other engineering projects.

5. Economic and environmental protection: Reduce the use of traditional materials such as sand and gravel, lower costs, and be environmentally friendly.

Product Introduction:

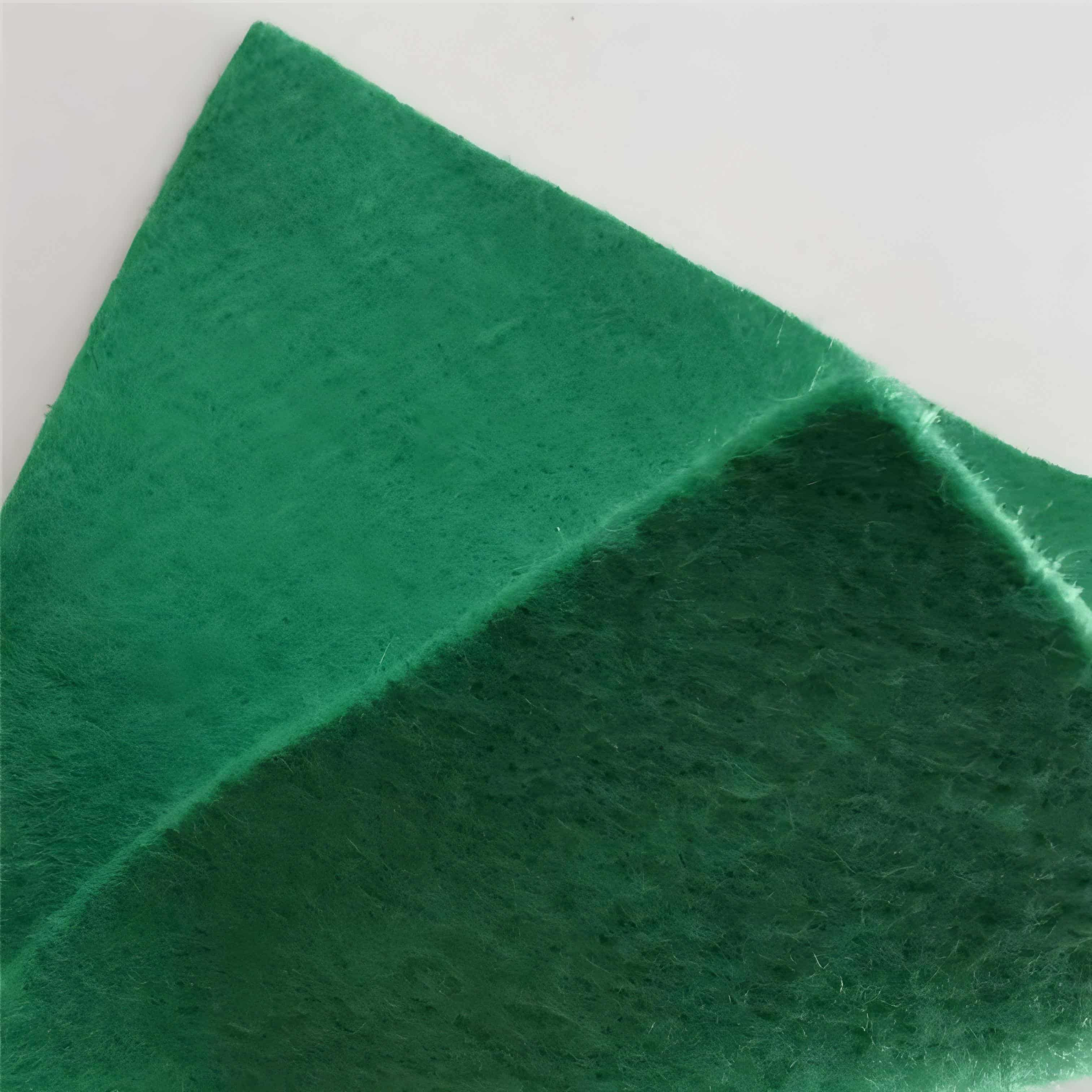

Riprap Geotextile Fabric is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. Its finished product is in the form of cloth, with a width of usually 4-6 meters (some up to 9 meters) and a length of 50-100 meters. It is divided into two categories: woven geotextile (high-strength) and non-woven filament geotextile (with good permeability).

characteristic

1. Diverse materials: The raw materials are mostly synthetic fibers such as polypropylene, polyester, nylon, etc., which have good chemical stability and weather resistance.

2. Special structure: divided into different types such as needle punched non-woven geotextile, woven geotextile, and woven geotextile, each type of structure endows it with specific properties. For example, needle punched non-woven geotextile has a soft texture and good breathability, while woven geotextile has higher strength.

3. Controllable permeability: The permeability of geotextiles can be adjusted according to different manufacturing processes and applications, which can meet drainage requirements and to some extent prevent the loss of soil particles.

4. Strong corrosion resistance: It has good resistance to chemical substances such as acids, bases, and salts, and can maintain stable performance in different soil and water quality environments.

5. Convenient construction: lightweight, flexible, easy to transport, cut and lay, able to adapt to different construction sites and complex terrain conditions.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam engineering

Anti seepage and anti filtration: laying geotextile inside the dam to form an anti-seepage layer, preventing seepage from causing damage such as piping and soil flow; At the same time, as an anti filter layer, it allows water to pass through while retaining soil particles, maintaining the stability of the dam structure.

Rivers and reservoirs

Slope protection and erosion prevention: Laying geotextile on river slopes to resist water erosion and reduce soil erosion; Laying at the bottom of the reservoir can prevent water flow from scouring the dam foundation.

Drainage system

Efficient drainage: Geotextile serves as a drainage channel to collect and discharge excess moisture from the soil, preventing soil saturation and rising groundwater levels.

2. Transportation Engineering

Road grassroots

Isolation and Stability: Installed between the road base and sub base, it isolates aggregates of different particle sizes to prevent mixing and ensure the stability of the structural layer.

Railway track bed

Drainage and isolation: prevent ballast from being embedded in the roadbed and extend the service life of the railway; At the same time, the drainage function reduces the damage of accumulated water to the road surface.

Airport runway

Anti settlement and reinforcement: As a foundation reinforcement material, it enhances the bearing capacity of the foundation and prevents uneven settlement.

3. Environmental Protection Engineering

Landfill site

Anti seepage and isolation: composite geotextile is laid at the bottom layer to block the pollution of groundwater by leachate from garbage; The top cover layer uses UV resistant geotextile to extend its service life.

Sewage-treatment plant

Anti seepage and anti-corrosion: used for anti-seepage of regulating tanks, sedimentation tanks and other tank bodies to prevent sewage leakage; At the same time, as a filtering material for biofilters, it improves treatment efficiency.

Soil remediation

Isolation of Pollution: Separate contaminated soil from uncontaminated soil to prevent the spread of pollution.

4. Construction and Municipal Engineering

Basement waterproofing

Enhance waterproof performance: When used in conjunction with waterproof coatings, rolls, etc., multiple waterproof lines are formed.

Roofing

Tear resistance and puncture resistance: As a reinforcing material, it improves the tear resistance and puncture resistance of the waterproof layer.

Green belts and roof greening

Weed prevention and water retention: prevent weed growth while maintaining soil moisture to promote plant growth.

5. Agriculture and Ecological Engineering

Farmland drainage

Improving the drainage system: constructing drainage channels to prevent water accumulation in farmland and increase crop yields.

Greenhouse

Foundation reinforcement: prevent foundation settlement and ensure the stability of the greenhouse.

Ecological Restoration

Vegetation restoration and slope protection: Fix the soil on the slope surface, prevent soil erosion, and promote vegetation growth.

Geotextiles have become an indispensable "invisible guardian" in modern engineering due to their excellent performance and wide applicability. From highways spanning thousands of miles to family gardens, from deep-sea dams to landfills, it carries a rigid mission with its flexible body, using the power of technology to safeguard the harmonious coexistence between humans and nature.