Soil Stabilization by Geotextiles and Fabrics

1. Strengthening soil mass: enhancing soil shear and bearing capacity, reducing settlement deformation caused by loads, and avoiding structural collapse

2. Corrosion and Loss Prevention: Resist rainwater erosion and water flow erosion, prevent soil particle migration, and maintain slope/roadbed stability

3. Strong adaptability: Flexible and adaptable to complex terrains such as potholes and steep slopes, without blind spots, compatible with various construction scenarios

4. Long term economic benefits: Convenient laying, labor-saving, and material saving, reducing project costs, while extending soil stability period and reducing maintenance

Products Introduction:

Soil Stabilization by Geotextiles and Fabrics is an engineering solution that enhances soil structural stability by laying functional geotextiles or geotextiles and utilizing their reinforcing, isolating, and restraining effects. This system uses polymer fibers such as polypropylene (PP) and polyester (PET) as the core raw materials to produce woven, needle punched composite or reinforced geotechnical products, which are laid inside or on the surface of the soil. Through the "soil fabric synergy", it solves the problems of "insufficient bearing capacity, easy settlement, weak erosion resistance" of soft soil, loose soil, backfill soil and other foundation soils, and provides lightweight and low-cost soil reinforcement solutions for road, slope, building foundation and other projects.

Product Features:

1. Reinforcement synergy enhances soil bearing capacity

Geotextile/fabric is a three-dimensional network structure formed by interweaving fibers, tightly interlocking with soil particles to form a "composite stable layer". Its longitudinal and transverse fracture strength can reach 20-80kN/m, effectively transmitting and dispersing local loads borne by the soil (such as vehicle compaction and building self weight), reducing soil shear stress, increasing soil shear strength by 30% -60%, and bearing capacity by 2-3 times, avoiding settlement and collapse caused by load concentration, and adapting to heavy load scenarios such as roadbeds and building foundations.

2. Constraint resistance to prevent soil erosion and migration

The dense structure of fabrics can constrain the displacement of soil particles and prevent loose and sandy soils from undergoing particle migration under the influence of rainwater erosion and water flow infiltration; At the same time, as a physical barrier, it isolates soil layers of different gradations to prevent fine soil from mixing with coarse aggregate layers and causing structural failure. In slope protection, it can effectively suppress soil collapse and soil erosion, maintain slope stability, and adapt to erosion prone scenarios such as slopes in rainy areas and river bank slopes.

3. Flexible and adaptable, suitable for complex terrain conditions

The product combines toughness and ductility, with a fracture elongation controlled at 15% -40%. It can naturally fit irregular terrains such as potholed roadbeds, curved slopes, and steep base surfaces (with a slope of ≤ 60 °), without blind spots for laying. Lightweight design (with a weight of 150-500g/m ²) makes it easy to handle and cut, even in narrow excavations, curved ditches and other limited construction spaces, laying can be completed manually, solving the pain points of traditional rigid stable materials that are difficult to bend and prone to cracking.

4. Weather resistant and creep resistant, ensuring long-term stability effect

The raw materials have undergone anti UV, anti acid and alkali, and anti biodegradation treatments, and can work stably in the extreme temperature range of -35 ℃ to 85 ℃. They are resistant to erosion from saline alkali soil, groundwater immersion, and outdoor sun and rain exposure. Excellent creep resistance, with a deformation rate of less than 5% under long-term constant load, ensuring that the soil structure maintains a stable shape for a long time, with a service life of up to 10-20 years, greatly reducing the frequency of later maintenance.

5. Environmental protection economy, optimizing the full cycle cost of engineering

No need to add chemical amendments, avoiding damage to the soil ecological environment, in line with the concept of green engineering; Compared with traditional replacement and concrete reinforcement methods, the material procurement cost is reduced by 25% -45%, the construction efficiency is improved by 2-3 times (the manual laying speed reaches 500-800 square meters/day), the construction period is shortened while reducing labor and equipment investment, and the long-term maintenance cost is reduced by more than 40%. It is suitable for cost sensitive rural roads, large-scale slope reinforcement and other projects.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and Traffic Engineering

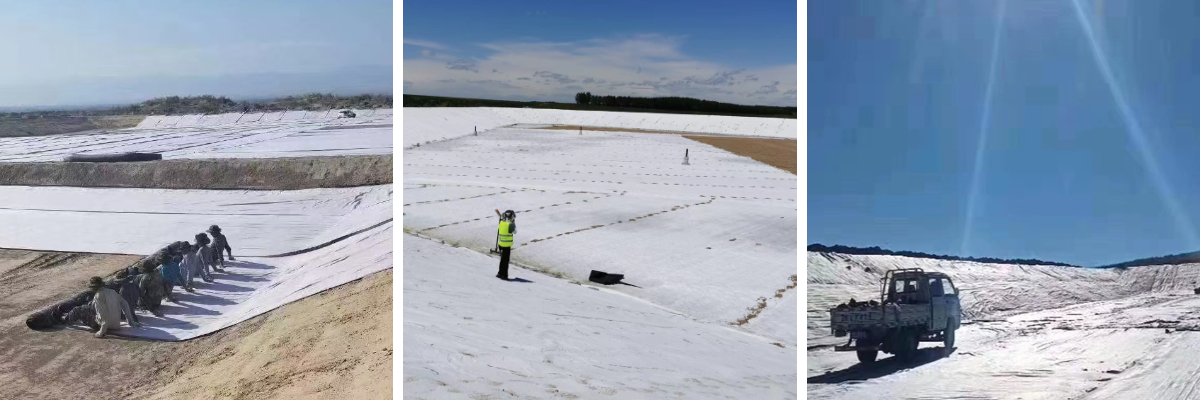

Roadbed reinforcement: laid between soft soil subgrade and crushed stone cushion layer, forming a reinforced composite layer to enhance the bearing capacity of the subgrade, prevent subgrade settlement and pavement cracking caused by long-term vehicle compaction, and adapt to projects such as highways, rural roads, and heavy-duty freight roads.

Stability of pavement base layer: Lay geotextile between asphalt/concrete surface layer and base layer to reduce reflection cracks, enhance interlayer bonding strength, while suppressing the migration of soil particles in the base layer, extending the service life of the pavement, and adapting to old road renovation and new municipal road projects.

2. Slope and hydraulic engineering

Slope protection: Geotextile is laid on highway slopes, mine waste dump slopes, and river bank slopes, combined with spraying green or ecological bags, to form a "reinforced ecological" composite protection system to prevent slope collapse and soil erosion, suitable for mountainous highway slopes and river ecological management projects.

Dam reinforcement: used for stabilizing the soil of reservoirs and river dams, laid inside the dam body or on the upstream slope to enhance the anti sliding stability of the dam body, prevent soil particle infiltration and loss, and adapt to small and medium-sized dam reinforcement and flood control embankment protection projects.

3. Construction and Site Engineering

Building foundation treatment: laying geotextiles in weak foundations and backfilled soil foundations to enhance the overall integrity of the foundation, reduce building settlement and wall cracking, and adapt to the foundation reinforcement of multi story buildings, factories, warehouses, and other buildings.

Site leveling and compaction: used for soil stabilization in large areas such as industrial parks and parking lots. It is laid between the soil surface and the gravel cushion layer to improve the compaction and bearing capacity of the site, prevent later settlement and deformation, and adapt to industrial site development and logistics park construction.

4. Agricultural and Landscape Engineering

Terraced Fields and Agricultural Road Stability: Geotextile is laid on the soil base of terraced fields and agricultural mechanized roads in mountainous areas to enhance soil stability, prevent terrace collapse and agricultural road damage caused by rainwater erosion, and adapt to agricultural comprehensive development and rural revitalization projects.

Landscape site reinforcement: used for slope site and artificial terrain reinforcement in garden landscapes, laid between soil and landscape cover layer to maintain stable terrain shape, while preventing soil erosion and pollution of landscape water bodies, suitable for park and scenic area landscape engineering.

Soil Stabilization by Geotextiles and Fabrics is a "green and efficient solution" for soil reinforcement in modern geotechnical engineering, with the core advantages of "reinforced collaborative strong bearing, restrained anti loss and anti erosion, flexible adaptation to square landscapes, environmental protection and economic longevity". It accurately solves the core pain points of "difficult soil stability, high construction costs, and significant environmental impact" in various engineering projects.