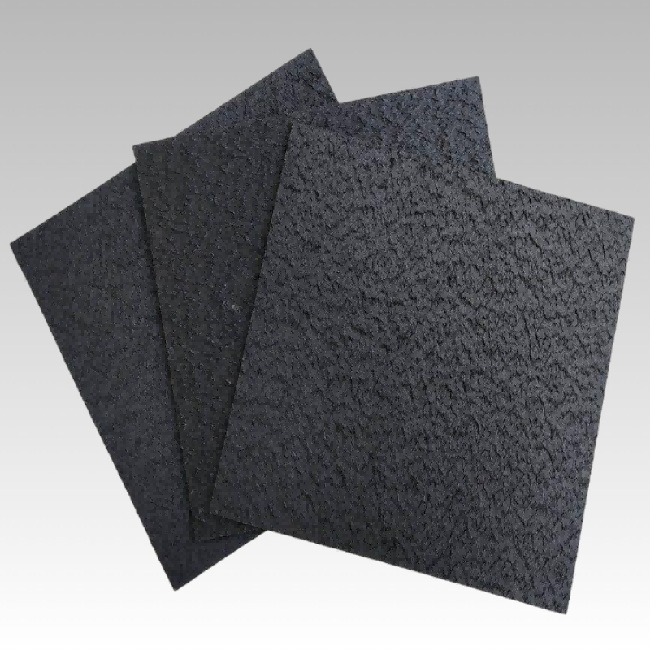

Geomembrane For Sale

1.Good anti-seepage effect:The molecular structure is dense and the anti-seepage coefficient is high, which can effectively block the infiltration of various liquids and is suitable for high anti-seepage demand scenarios.

2.Strong durability:Acid and alkali resistance, corrosion resistance, anti-aging, service life of more than 50 years, can play a long-term stable role.

3.Convenient construction and transportation:Lightweight, flexible, easy to transport and lay, suitable for complex terrains, and can shorten construction time.

4.Diverse functions:In addition to anti-seepage, it can also isolate, reinforce, and protect, and the composite type can meet multiple engineering needs simultaneously.

5.High cost-effectiveness:Low material, construction, and maintenance costs, long service life, and can save overall project expenses.

Product Introduction

The core function of geomembrane

The functions of Geomembrane For Sale are diverse, with core functions centered around the requirements of engineering construction.

Anti seepage is its main function. With the density of polymer materials, it can effectively prevent the infiltration of liquids such as water, sewage, and chemical solutions, and play a key role in projects such as reservoirs, landfills, and sewage treatment tanks.

The isolation function can separate materials of different properties, such as soil and sand, sand and stone, to avoid mixing and affecting the stability of engineering structures. This function is commonly used in road base isolation layers.

The geotextile in composite geomembrane can enhance the tensile strength of soil, reduce soil deformation, play a reinforcing role, and improve the overall stability of the project. It is suitable for soft soil foundation treatment, slope reinforcement and other scenarios.

In addition, it can also protect soil or other structures from water erosion and erosion, demonstrating good protective functions in river regulation and dam protection projects.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

1、 Water conservancy engineering field

In hydraulic engineering, geomembrane is an important anti-seepage material. During the construction of reservoirs and dams, laying geomembranes can effectively prevent water seepage from the reservoir or dam body, ensuring the water storage capacity and structural safety of water conservancy facilities; The use of geomembranes in channels and irrigation systems can reduce leakage losses of water resources during transportation, improve irrigation efficiency, and is particularly suitable for agricultural irrigation projects in arid and water scarce areas.

2、 Environmental engineering field

Environmental engineering has extremely high requirements for anti-seepage, and geomembranes play a crucial role in this regard. In landfills, geomembranes serve as the core anti-seepage layer, which can tightly block the leachate from garbage and prevent it from penetrating into the soil and groundwater, thus avoiding environmental pollution; The sedimentation tank, reaction tank and other facilities of the sewage treatment plant are equipped with geomembranes to prevent leakage, ensuring the orderly progress of the sewage treatment process and preventing sewage leakage from polluting the surrounding environment.

3、 Municipal engineering field

In municipal engineering, the application scenarios of geomembranes are diverse. When constructing landscape water bodies such as artificial lakes and landscape pools, using geomembranes for anti-seepage treatment can ensure stable water volume and maintain the landscape effect; Laying geomembrane on the roof of an underground garage can effectively prevent rainwater or groundwater from seeping into the garage; During the construction of subway tunnels, geomembranes are used for anti-seepage and moisture-proof purposes, ensuring the dryness of the tunnel interior and providing environmental support for the safe operation of the subway.

4、 Transportation engineering field

In transportation engineering, geomembranes are mainly used for foundation treatment and anti-seepage. When treating soft soil foundations of highways and railways, geomembranes can play a role in isolation, separating soft soil from other fillers. At the same time, composite geomembranes can enhance the bearing capacity of the foundation and reduce roadbed settlement; Laying geomembrane as an anti-seepage layer on the roadbed can prevent rainwater from infiltrating into the foundation, avoid the strength of the foundation from decreasing after being soaked in water, and thus ensure the structural stability of roads and railways.

5、 Mining engineering field

In mining engineering, geomembranes are mainly used in tailings ponds. Tailings pond is a place for storing waste such as slag. Laying geomembrane can form an anti-seepage barrier to prevent harmful substances in slag from infiltrating into the surrounding soil and groundwater with rainwater, protecting the ecological environment of the mining area and surrounding areas, and reducing environmental pollution risks.

In summary, geomembranes have irreplaceable applications in many engineering fields such as water conservancy, environmental protection, municipal engineering, transportation, and mining due to their excellent anti-seepage, isolation, and reinforcement properties. It not only ensures the structural safety and stable operation of various projects, but also plays an important role in water resource protection, ecological environment maintenance, and other aspects. It is an indispensable key material in modern engineering construction.