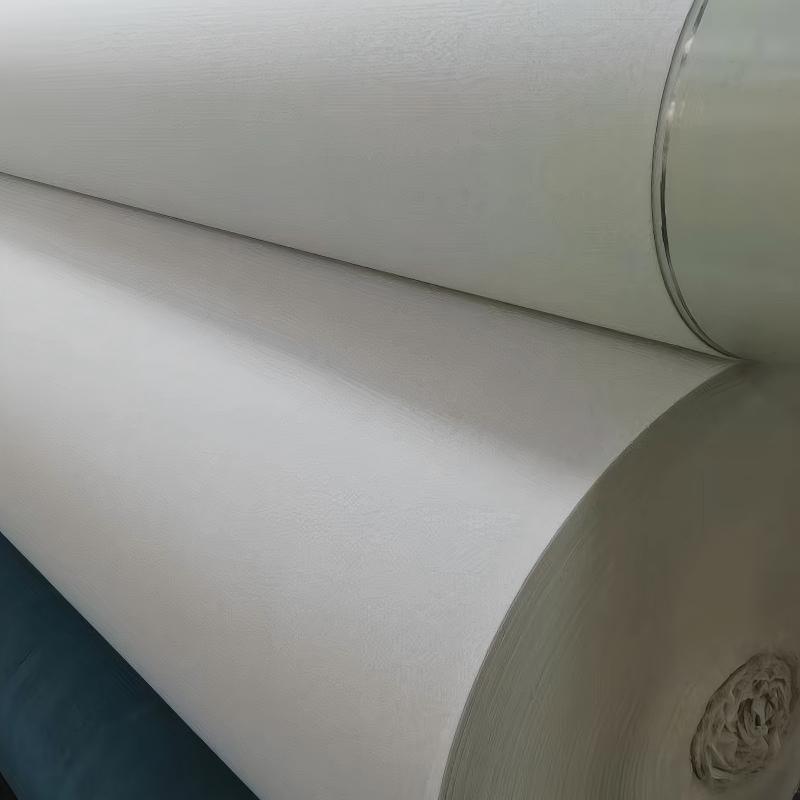

Non Woven Geotextile Fabric 8 oz

1. Good filtering performance:It can allow water to pass through while blocking soil particle loss, maintaining structural stability, and is suitable for drainage and filtration scenarios.

2. Efficient drainage:There are many pores inside, which can quickly drain water and reduce the water level and pressure in the soil.

3. Strong reinforcement effect:Enhance the tensile and shear resistance of soil, reduce deformation, and improve the stability of engineering structures.

4. Excellent protective effect:Protect soil or other materials from water flow erosion and external wear, and extend the service life of the project.

5. Convenient construction:Lightweight, flexible, easy to lay, adaptable to complex terrains, and saves construction time.

6. Excellent durability:Acid and alkali resistance, corrosion resistance, stable performance in various environments, and long service life.

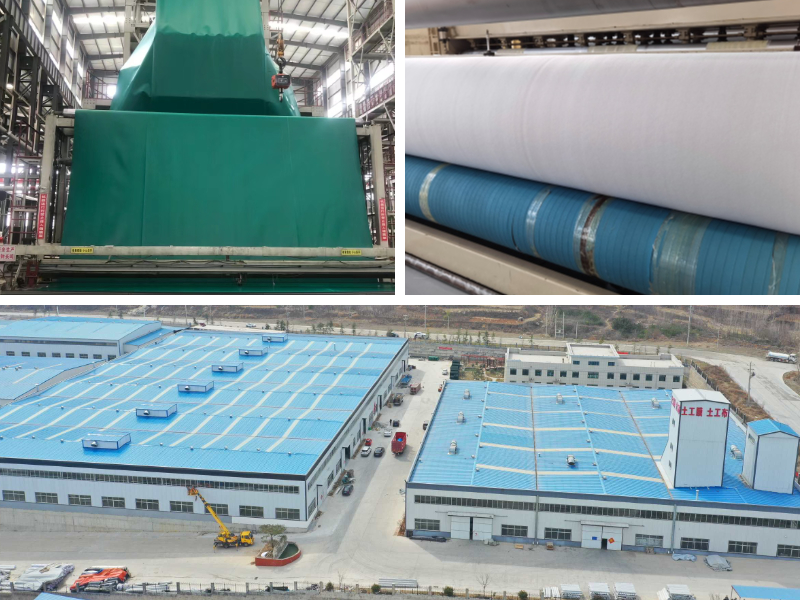

Product Introduction

Core functions

1.Filtering function: When water flows through Non Woven Geotextile Fabric 8 oz, its internal fiber structure can intercept solid particles such as soil particles and sand particles in the water, preventing them from flowing away with the water and avoiding damage to the soil structure. At the same time, the pores of geotextiles can ensure the smooth passage of water, maintain the permeability stability of the soil, and keep the engineering structure stable in long-term use. For example, in the filter layer of a dam, geotextile can effectively prevent the soil of the dam from being carried away by seepage water, protecting the safety of the dam.

2.Drainage function: Geotextiles themselves have a large number of interconnected pores, which form drainage channels that can quickly drain excess water from the soil. In engineering, it can collect seepage, surface water, or groundwater from the soil, and guide the water to the designated drainage system through its own hydraulic conductivity, thereby reducing the pore water pressure in the soil and minimizing soil deformation, landslides, and other problems caused by excessive water pressure. For example, in highway subgrades, geotextiles can timely discharge accumulated water from the roadbed and protect its strength.

3.Reinforcement function: Geotextile has a certain tensile strength and elastic modulus. When laid in soil, it can generate friction with the soil, limiting the lateral displacement and vertical deformation of the soil. When the soil is subjected to external forces, geotextiles can share some of the stress and evenly transmit it to a larger range, thereby improving the overall stability and bearing capacity of the soil. In soft soil foundation treatment, geotextile can enhance the shear strength of the foundation, reduce foundation settlement, and ensure the safety of the upper structure.

4.Protective function: Geotextile can cover the surface of soil or other structures to form a protective layer, blocking direct erosion and wear of soil or structures by water flow, wind waves, vehicles, etc. For example, in river regulation projects, geotextiles laid on river slopes can resist the erosion of water flow and prevent soil erosion on the slopes; In road construction, geotextiles can protect the roadbed from being crushed and damaged by construction machinery, while reducing the mixing of pavement materials and roadbed soil, ensuring the performance of the pavement structure.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1、 Water conservancy engineering field

In hydraulic engineering, geotextiles are commonly used in areas such as dams and rivers. As an anti filter layer, it can prevent soil particles in the dam or river slope from being carried away by water flow, while allowing water to be smoothly discharged, ensuring the stability of the dam and river slope; In anti-seepage engineering, it can serve as a protective layer for geomembranes to prevent them from being punctured by sharp objects and extend the service life of the anti-seepage system; In addition, it can also be used for channel reinforcement to reduce the erosion of water flow on the channel.

2、 Transportation engineering field

Geotextiles are widely used in highway and railway construction. During roadbed treatment, laying geotextile can serve as reinforcement, enhance the bearing capacity of the roadbed, and reduce roadbed settlement; As a filtering layer, it can prevent fine particles in the roadbed from entering the base layer and prevent damage to the base structure; Between the road surface and the base layer, different materials can be isolated to prevent their mixing from affecting road performance, while also helping to drain accumulated water from the road structure.

3、 Environmental engineering field

Geotextile is an important material in environmental engineering. In landfills, it can serve as an isolation and filtration layer to prevent impurities in the leachate from contaminating the soil and groundwater, while promoting the discharge of leachate; The sedimentation tank, filtration tank and other facilities of the sewage treatment plant can use geotextile to filter impurities in the water and improve the sewage treatment effect; In ecological restoration projects, it can be covered on the soil surface to prevent soil erosion and create a favorable environment for plant growth.

4、 Municipal engineering field

Geotextiles are used in various scenarios in municipal engineering. When laying underground pipelines, the geotextile surrounding the pipeline can buffer soil pressure, protect the pipeline from damage, and facilitate drainage; Slope treatment of artificial lakes and landscape rivers, laying geotextiles can prevent slope soil from being washed away by water and maintain the stability of landscape water bodies; In areas such as road green belts and park lawns, it can play a role in water retention and soil compaction prevention.

Geotextiles play a crucial role in various engineering fields such as water conservancy, transportation, environmental protection, and municipal engineering due to their diverse functions of filtration, drainage, reinforcement, and protection. It not only ensures the structural stability and safe operation of various projects, but also makes significant contributions to ecological protection, resource utilization, and other aspects. It is an indispensable and important material in modern engineering construction.