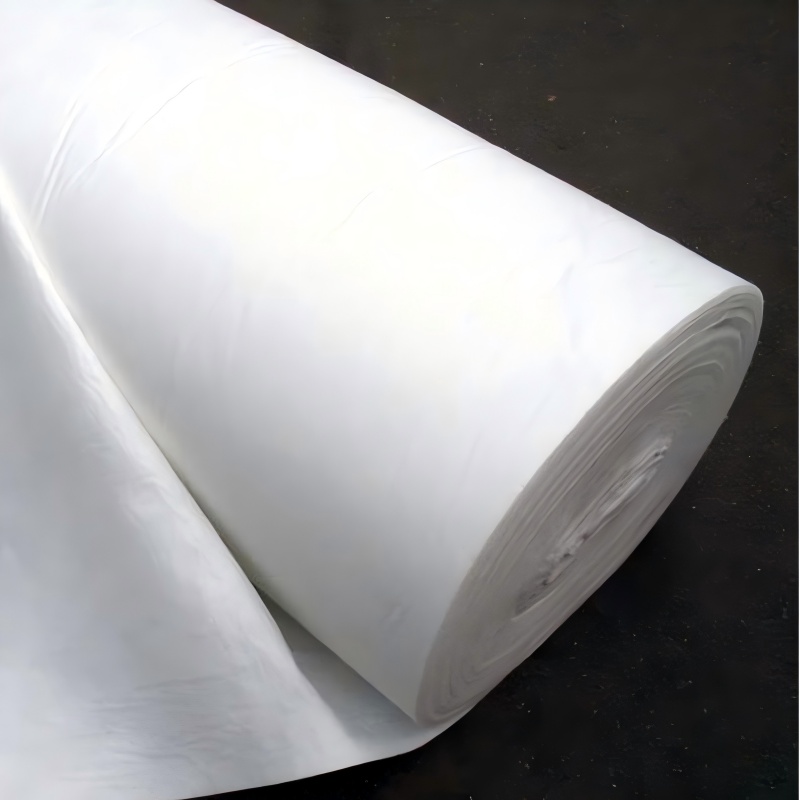

Geotextile Fabric 150gsm

1. Strong integrity: As a continuous whole material, it can more evenly distribute loads and reduce local damage.

2. Ensure engineering quality: Its stable performance and uniform specifications help achieve the expected results of engineering design and improve the consistency of engineering quality.

3. Shorten the construction period: The construction is simple and fast, which can significantly reduce the amount of earthwork excavation and material transportation, thereby shortening the construction period.

4. Reduce engineering costs: Overall, the use of geotextiles can save a lot of labor, material, and machinery costs, and has significant economic benefits.

5. Durable and environmentally friendly: With a long service life, it reduces the frequency of maintenance and replacement. Meanwhile, it can effectively prevent soil erosion and protect the ecological environment.

Product Introduction:

Geotextile Fabric 150gsm is a permeable roll shaped polymer material made of synthetic fibers (such as polypropylene, polyester, nylon, etc.) through methods such as needle punching, weaving, or thermal bonding. It belongs to a type of "geotechnical material" specifically designed for use with soil, rock, or other geotechnical materials to enhance, drain, filter, isolate, or protect.

Simply put, geotextile is the "cloth" used in civil engineering, which plays a multifunctional role in engineering structures and is an indispensable new material in modern engineering construction.

Feature

The reason why geotextiles are widely used is due to their following core characteristics:

High strength and durability: Made of synthetic fibers, it has excellent tensile, tear, burst, and puncture strength, and can withstand various loads during construction and long-term use. At the same time, it is corrosion-resistant, resistant to microorganisms and insect infestations, and can maintain long-term stability in various harsh soils and waters.

Good permeability and filtration: There are countless continuous gaps inside the geotextile, which can allow water to pass smoothly and effectively prevent excessive loss of soil particles, playing a "filtering" role, preventing soil erosion and foundation hollowing.

Isolation function: Laying between two different types of soil or materials can prevent them from mixing with each other, maintaining their respective structural integrity and performance. For example, to prevent crushed stones from sinking into soft soil foundations.

Protective function: It can serve as a buffer layer, dispersing and concentrating stress, reducing damage to waterproof layers (such as geomembranes) from external impacts or punctures.

Reinforcement effect: When buried in soil, its tensile strength can be used to improve the stress distribution of the soil, enhance its strength and stability, similar to adding steel bars to concrete.

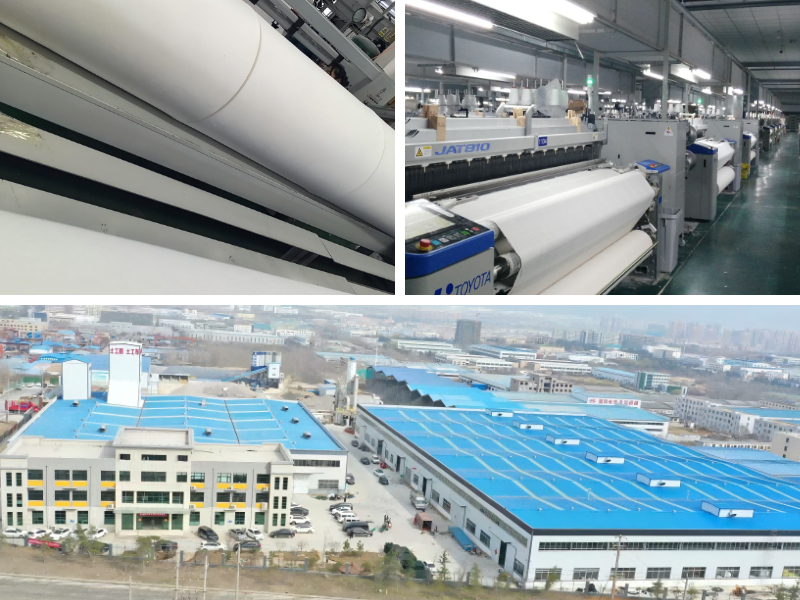

Easy construction and high efficiency: Geotextiles are supplied in the form of rolls, which are lightweight, easy to transport and lay, and can greatly shorten the construction period and reduce labor intensity.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering: The core solution is to prevent erosion, filter water, and prevent seepage

Embankment/reservoir: Lay geotextile (often combined with geomembrane) on the upstream slope of the embankment to prevent water flow from scouring the soil; Lay it inside the dam as a filter layer to prevent soil particles from flowing away with seepage and prevent the dam from piping.

River management: Lay geotextile on the slope of the river, use ecological bags to reinforce the slope, prevent soil erosion, and ensure the infiltration and exchange of water and soil, which is conducive to the growth of aquatic plants.

Irrigation area channel: Lay geotextile at the bottom and slope of the channel to reduce channel leakage (with an anti-seepage rate of over 98% when combined with geomembrane), while protecting the geomembrane from sharp soil particles.

2. Transportation infrastructure: core solution of "reinforcement, isolation, and maintenance"

Highway/railway subgrade: Lay geotextile between subgrade fillers (such as gravel layer and plain soil layer) to isolate materials of different particle sizes and prevent plain soil from squeezing into the gravel layer and causing subgrade compaction; Laying in soft soil subgrade sections as a reinforcement layer to enhance the tensile strength of the subgrade and reduce settlement (can reduce subgrade settlement by 20% -40%).

Road maintenance: During the renovation of old road surfaces, geotextiles are laid between the old asphalt layer and the new asphalt layer to prevent reflection cracks and prevent them from extending to the new road surface, thus extending the service life of the road surface.

Bridge engineering: Lay geotextile at the junction between the bridge abutment and the roadbed to reduce differential settlement between the backfill soil and the roadbed, and avoid the problem of "bridge head jumping".

3. Environmental engineering: core solution to "prevent pollution and isolate harmful substances"

Landfill site: A composite anti-seepage system of "geotextile+geomembrane" is laid at the bottom and surrounding areas of the landfill site. Geotextile serves as a protective layer to prevent sharp objects from puncturing the geomembrane, and also as a filter layer to collect leachate (garbage leachate is discharged to the collection pipe through geotextile), avoiding pollution of groundwater.

Sewage treatment plant: Lay geotextile at the bottom of the sewage treatment tank as a filter layer to filter impurities in the sludge and protect the anti-seepage layer of the tank body; Lay in the sludge drying field to accelerate sludge dewatering (by guiding and draining moisture through geotextiles).

Ecological restoration: In mining restoration and saline alkali land improvement projects, geotextiles are laid to isolate polluted soil layers from clean soil, prevent the spread of harmful substances, and ensure water infiltration, creating conditions for vegetation planting.

4. Urban infrastructure: core solutions for "permeability, reinforcement, and protection"

Sponge City: Laying geotextile on the lower layer of permeable pavement as a filtering layer to prevent sand and gravel from entering the permeable surface layer, while directing rainwater to underground reservoirs to improve the permeability efficiency of the pavement.

Underground engineering: laying geotextile on the outside of subway tunnels and underground pipe galleries as a drainage layer to collect water seepage around the tunnel and prevent it from entering the interior of the tunnel; Lay on the foundation of the pipe gallery as a reinforcement layer to enhance the bearing capacity of the foundation.

Roof greening: Lay geotextile between the "waterproof layer and planting soil" of the roof greening to isolate the planting soil from the waterproof layer, prevent soil particles from blocking the drainage holes of the waterproof layer, and protect the waterproof layer from being penetrated by plant roots.

Geotextile, as a high-performance geotechnical material, has become a "standard" in modern infrastructure construction due to its multifunctionality, economy, and environmental friendliness. It solves complex geotechnical engineering problems through simple physical principles and is an important symbol of technological progress in civil engineering.