Geo Fabric for Drainage

1. Functional versatility: It has multiple functions such as filtration, drainage, isolation, and reinforcement, reducing the variety of engineering materials.

2. Construction efficiency: Lightweight and easy to lay, can significantly shorten the construction period and reduce construction costs.

3. Environmental friendliness: Polymer materials can be recycled and reused, and the construction process has minimal impact on the surrounding ecology.

4. Strong durability: corrosion resistance, aging resistance, service life up to 10-50 years, reducing later maintenance costs.

Product Introduction:

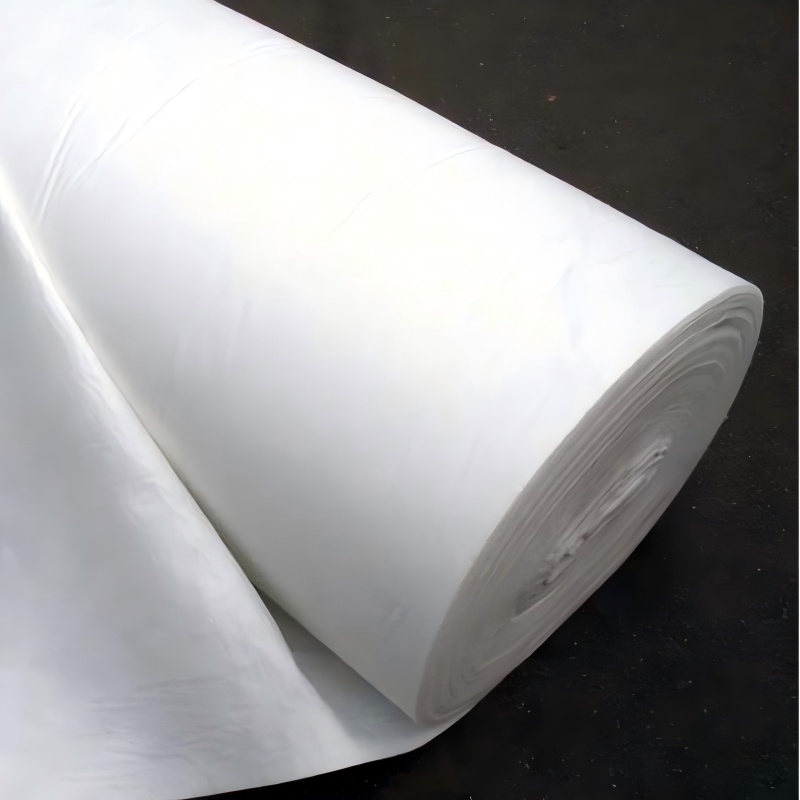

Geo Fabric for Drainage is a permeable geosynthetic material made from synthetic fibers (such as polypropylene, polyester, nylon, etc.) through processes such as needle punching or weaving. It is essentially "fabric used in civil engineering" and is the most widely used material in geotechnical engineering, mainly used for reinforcement, isolation, filtration, drainage, protection, and other purposes.

It is usually in the form of a roll, easy to transport and lay, and is an indispensable basic material in modern engineering construction.

Main Features

The reason why geotextiles can be widely used in various engineering projects is due to their following core characteristics:

1. High strength: It has good tensile, tear, burst, and puncture resistance, can disperse loads, and improve soil stability.

2. Strong durability: Made of synthetic fibers, it is corrosion-resistant, acid and alkali resistant, resistant to microorganisms and insect infestations, and can maintain long-term performance in different soils and waters.

3. Good permeability: The structure is loose and porous, allowing water to pass smoothly in a direction perpendicular to its plane, while effectively preventing the loss of soil particles and playing a filtering role.

4. Good flexibility: The texture is soft and can fit well with various shapes of base layers, adapting to uneven settlement of the foundation.

5.Easy construction: lightweight, roll supply, transportation, and laying are all very convenient, which can greatly improve construction efficiency and reduce labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Construction of highways and railways:

Isolation function: It is laid between the roadbed and ballast to prevent soil and stone from mixing, maintain the thickness and bearing capacity of the structural layer, and reduce uneven settlement.

Reinforcement function: increases the overall integrity and stability of the roadbed, disperses vehicle loads, and extends the service life of the road.

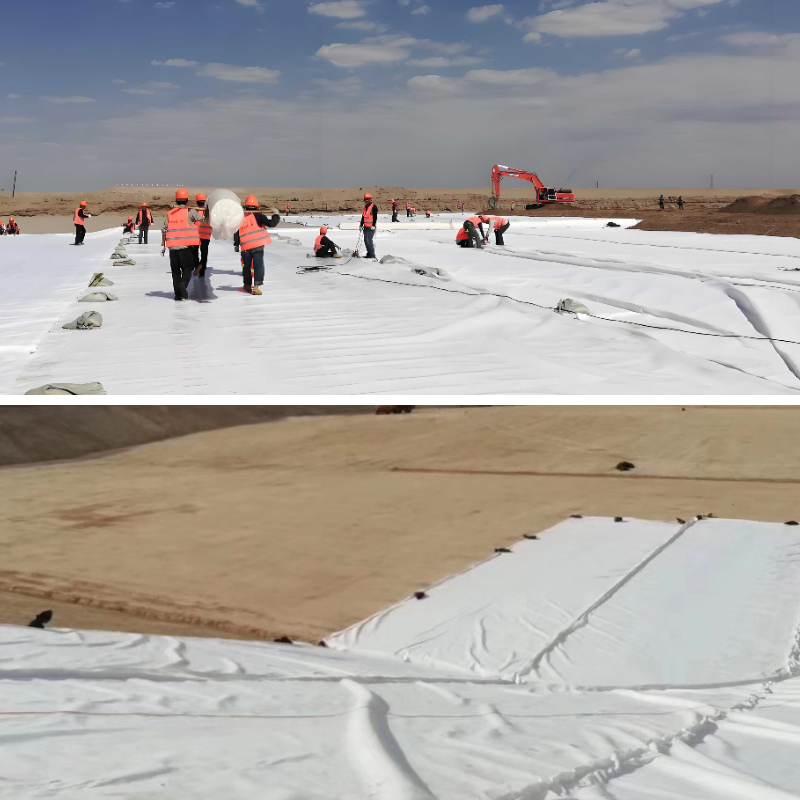

2. Water conservancy engineering (dams, rivers, coasts):

Anti filtration function: used for the back water surface of dams, slope protection, and retaining walls, allowing water flow to pass through while preventing soil particles from being carried away by water flow, avoiding piping and erosion.

Protective function: Used for anti erosion protection of riverbanks and coasts, buffering the impact force of water flow and waves.

3. Environmental engineering (landfill site):

Isolation and protection: As a component of the basic lining system and covering system of the landfill site, it isolates pollutants and protects the surrounding soil and groundwater.

Drainage and gas guidance: Combined with the drainage pipe network, it efficiently collects and guides leachate and exhaust gas.

4. Construction project:

Foundation drainage: laid around the basement and foundation to form a drainage layer, effectively removing accumulated water and reducing groundwater pressure.

Roof garden/underground garage roof drainage: used for planting roof systems, which can not only store water and moisture, but also discharge excess water to prevent root system blockage of drainage channels.

5. Other fields:

Airports and sports fields: Strengthen the soft foundation and stabilize the field.

Agriculture: used for crop weed prevention, insulation, moisture retention, etc.

Geo Fabric for Drainage, as an efficient engineering material, has achieved a revolutionary change of replacing soil and stone with cloth due to its excellent performance and economic benefits. It has become a key material in modern civil engineering construction to ensure safety, improve quality, save costs, and protect the environment.