Wastewater Sludge Dewatering Bags

1.Dehydration efficiency: Solid content reaches 30% -60%, significant volume reduction.

2.Lower cost: Less equipment, maintenance, and site expenses.

3.Wide adaptability: Capable of handling multiple types of sludge, with flexible scenarios.

4.Easy to operate: No need for complex equipment, easy to lay and use.

Product Introduction

1、 Basic attributes

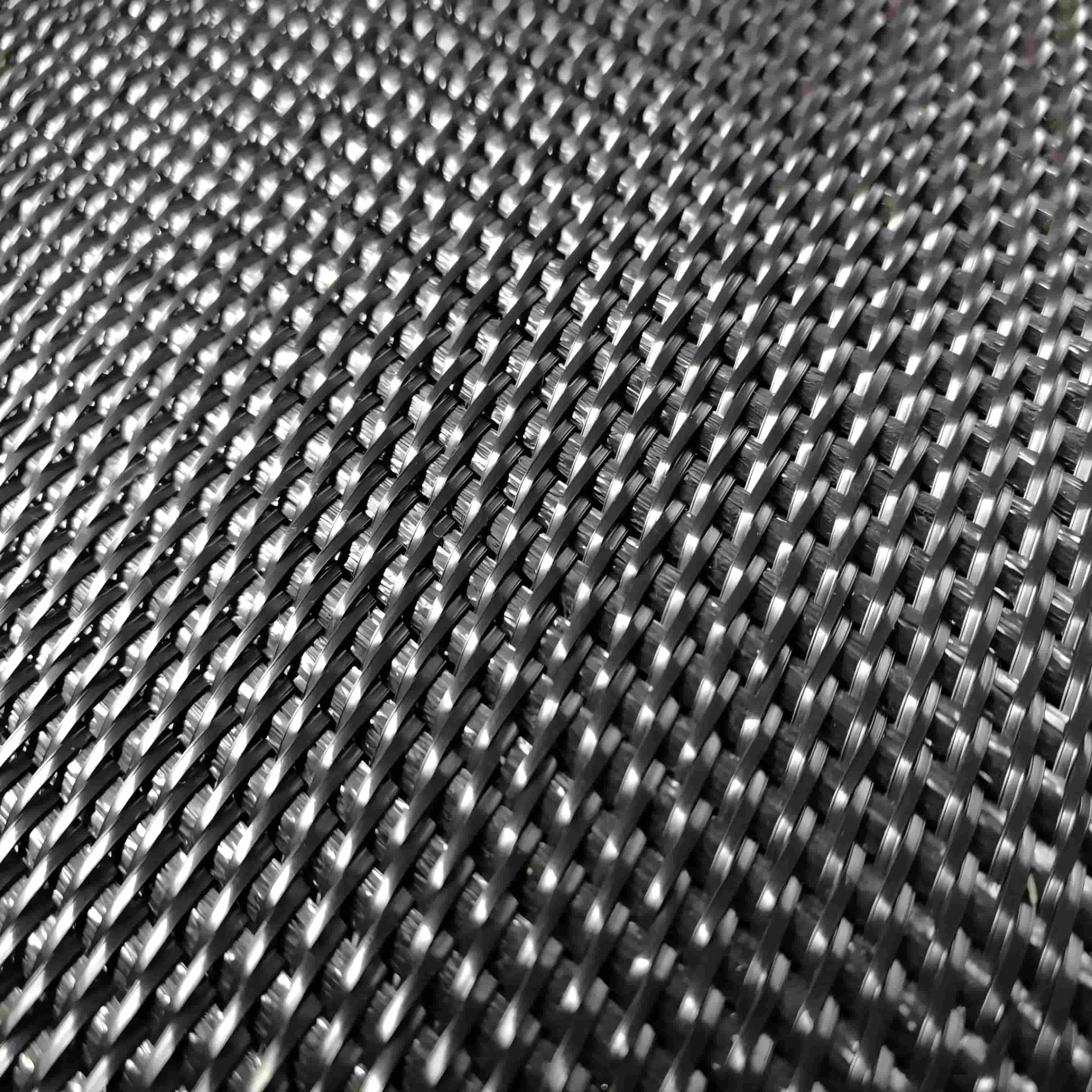

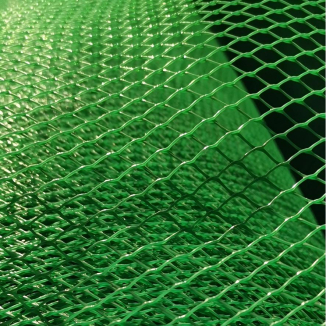

Material: Wastewater Sludge Dewatering Bags,with polypropylene, polyester and other polymer geotextiles as the core, some of them are coated with anti-aging and anti-corrosion coatings, making them durable.

Form: mostly tubular/bag shaped, customizable specifications, with feeding and exhaust ports, lightweight and easy to transport and store in empty bags.

Purpose: Dedicated to the field of environmental protection, processing municipal and industrial sludge and river dredging slurry, connecting sludge concentration and final disposal.

2、 Core functions

Dehydration: After injecting dilute sludge, the fabric intercepts solids and seeps out water, and then squeezes dry by pressure inside the bag, reducing the moisture content of the sludge to 40% -70%.

Capacity reduction: After dehydration, the solid content of the sludge reaches 30% -60%, and the volume is reduced to 1/3-1/10 of the original, reducing the cost of subsequent treatment.

Temporary storage and shaping: It can temporarily store sludge, form a stable "sludge cake" after dehydration, and facilitate subsequent transportation and disposal.

3、 Main features

Efficient: The dehydration cycle is controllable (several days to several weeks), without frequent operation, and the volume reduction effect is significant.

Economy: Low initial equipment investment, infrequent replacement of parts during operation and maintenance, low energy consumption, and can be installed outdoors without building a factory.

Wide adaptability: Flexible combination of single/multiple bags, capable of handling various types of sludge with solid content ranging from 1% to 10%, with strong scene compatibility.

Convenient and safe: easy to operate, stable material without secondary pollution, and the filtered water can be recycled and treated.

Product Parameters

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Application

1、 Municipal environmental protection field

Sludge treatment in sewage treatment plants: It is a core application scenario used to treat the residual sludge (usually with a moisture content of 80% -99%) generated by municipal sewage plants on a daily basis. After injecting dilute sludge into the bag for dewatering, a sludge cake with a solid content of 30% -60% is formed, which significantly reduces the transportation volume of sludge and lowers the cost and difficulty of subsequent landfilling, incineration, or resource utilization (such as producing nutrient soil and building materials).

River/Lake Dredging Project: For the high moisture content mud (with a solid content of 1% -5%) generated during the dredging of urban rivers and landscape lakes, geotextile bags are used for dewatering and volume reduction to prevent the mud from randomly piling up and polluting the surrounding soil and water bodies. The dewatered sludge can be used for reinforcing river bank slopes and backfilling green spaces, achieving resource recycling.

2、 Industrial wastewater treatment field

Sludge disposal in high pollution industries: Suitable for special sludge (containing heavy metals, organic matter, etc.) generated by industrial enterprises such as chemical, printing and dyeing, mining, and electroplating. The bag material is stable and does not undergo chemical reactions with sludge. During the dewatering process, harmful substances can be intercepted, reducing secondary pollution; The dehydrated sludge is easy to seal and transport to the hazardous waste treatment center, meeting environmental compliance requirements.

Centralized treatment in industrial parks: Used for centralized sludge treatment in industrial park sewage treatment stations, it can flexibly combine multiple bags according to the sludge production in the park, without the need to build large dewatering plants, reducing the investment in environmental protection facilities in the park, and adapting to the sludge treatment needs of small and medium-sized enterprises.

3、 In the field of water conservancy and infrastructure engineering

Mud treatment for dredging projects: In port, waterway dredging, or hydraulic engineering (such as reservoir dredging and dam reinforcement), the massive amount of mud generated from dredging operations is treated. Geotextile bags can be directly laid on the construction site for rapid dewatering and capacity reduction. The dewatered dry mud can be used for land reclamation and roadbed filling, reducing the occupation of marine or terrestrial environments by dredging waste soil.

Construction site mud recycling: For the construction mud generated during pile driving and underground continuous wall construction, it is dehydrated through geotextile bags and the filtered water can be recycled for construction. The dry mud is disposed of according to solid waste standards, achieving zero discharge of construction site sewage and meeting environmental protection requirements for construction.

Wastewater and sludge dewatering bags have become key sludge treatment tools in the three core areas of municipal environmental protection, industrial wastewater treatment, and water conservancy infrastructure, thanks to their advantages of efficient dewatering, flexible adaptation, and environmental friendliness and economy. It can not only solve the problem of reducing the capacity of high moisture sludge in different scenarios, reduce treatment costs, but also help various fields achieve environmental compliance and sustainable development through resource recycling (such as dry mud backfilling, water filtration cycle) and pollution control, especially suitable for on-site treatment of large-scale projects and centralized disposal needs of small and medium-sized enterprises. Its application value is wide and practical.