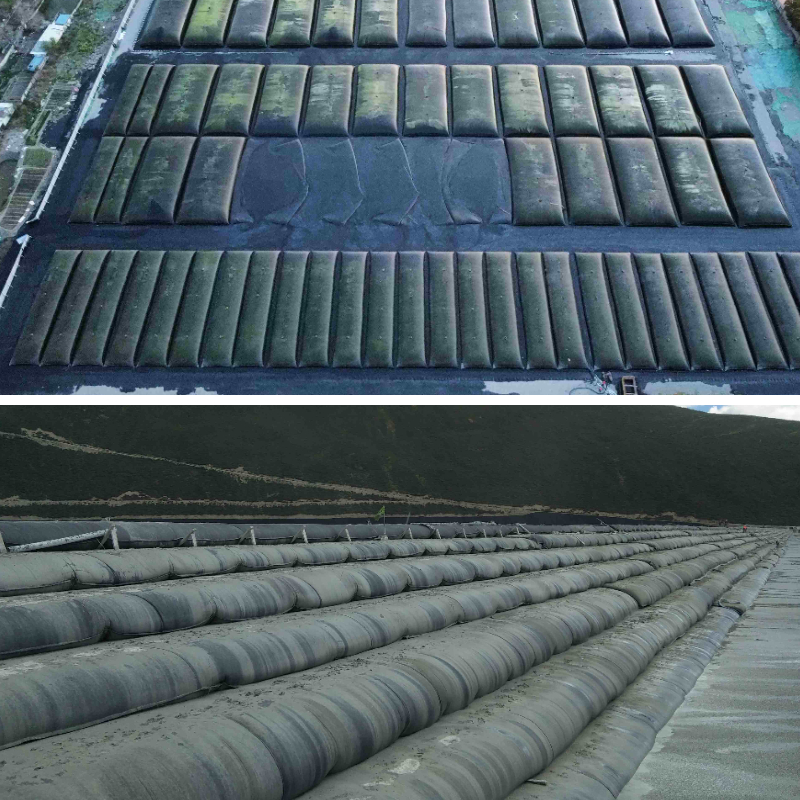

Sludge Dewatering Bags

Adapt to foundation deformation: Flexible structures can adapt to a certain degree of settlement and displacement, avoiding cracking of rigid structures (such as concrete) caused by uneven settlement.

Construction convenience: No large machinery is required. It can be filled and installed on-site, reducing construction costs.

High cost - performance ratio: Compared with concrete or traditional stone protection, the cost is reduced by 30%-50%, and the transportation volume is small.

Resource recycling and utilization: The dehydrated sludge can be used as building material raw materials, greening soil or agricultural improvers, achieving waste reduction and resource utilization.

Product Introduction:

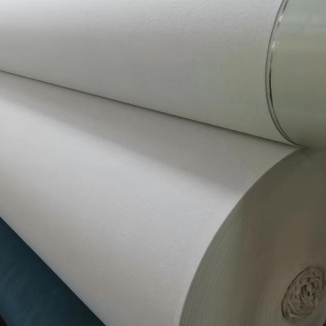

Sludge Dewatering Bags are tubular geosynthetic materials made of high-strength synthetic fibers (such as polypropylene and polyester) through a special weaving process. By filling them with granular materials like sand, tailings, and sludge, structural units with high strength and flexibility are formed.The core technical advantages are as follows:

Material Properties: High - molecular materials that are resistant to ultraviolet rays, acid and alkali, and microbial erosion are used, and the lifespan can reach 10 - 30 years (adjusted according to environmental conditions).

Structural Design: The surface of the bag is densely covered with small water - permeable holes (with a pore diameter of 0.05 - 0.2mm), which can quickly drain water, retain granular materials, and form a stable mechanical structure.

Product Parameters:

project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

Environmental Governance and Solid Waste Treatment

Sludge Dewatering and Disposal: In German sewage treatment plants, geotextile tubes are used for sludge thickening (reducing the moisture content from 95% to less than 60%), which is 30% lower in cost than traditional filter presses and causes no chemical pollution.

Tailings Dam Construction: In Australian mines, tailings sand is filled to form a retaining dam. The permeable design avoids water accumulation in the dam, and at the same time, ecological restoration is achieved through vegetation planting, meeting the ISO 14001 standard.

Hydraulic and Coastal Engineering

Coastal Protection: In coastal areas such as the Netherlands and Louisiana in the United States, it is used to build ecological seawalls and breakwaters, replacing traditional concrete structures, reducing costs by 40%, and providing habitats for coastal organisms at the same time.

River Regulation: In the river management in Southeast Asia, river sand is filled to form guide dikes to control the flow direction and reduce flood disasters. For example, in the Mekong River Delta project in Vietnam, the anti - scouring ability of the geotube embankment is 3 times higher than that of the natural riverbank.

Industrial and Infrastructure Projects

Temporary Cofferdam: During the construction of Saudi Arabian oil pipelines, geotextile bags filled with clay are used to form a temporary water-retaining cofferdam. The construction period is shortened by 2/3 compared with that of a concrete cofferdam, and it can be reused.

Landfill Site Closure: At the Canadian landfill site, geotextile bags filled with gravel are used as a gas exhaust layer in combination with an impermeable membrane, effectively controlling methane emissions and meeting the requirements of the Kyoto Protocol.

Agriculture and Ecological Engineering

Saline-alkali Land Improvement: In the Middle East, the tubes are filled with improved soil and laid on farmland to block the upward movement of underground salt. Combined with a drip irrigation system, the crop yield is increased by 60%.

Marshland Reinforcement: In the African wetland protection project, the tubes are filled with crushed stones to form the foundation of the plank road, reducing ecological damage while bearing the pedestrian load (≥20kN/m²).

The cross - industry application of geotextile tubes essentially lies in the technical adaptation of "flexible structure + material innovation": In the water conservancy field, its wave - resistance characteristics are utilized; in the environmental protection field, its solid - liquid separation advantages are brought into play; in civil engineering, its construction convenience is demonstrated; and in ecological scenarios, its sustainability is emphasized. In the future, with the development of material upgrades (such as degradable geotextiles, intelligent monitoring fabrics) and digital construction technologies (such as BIM - model - assisted design), its application scenarios will be further expanded towards intelligence and low - carbon, becoming a universal solution for infrastructure construction and environmental governance in multiple industries.