Geotube

High - efficiency water permeability and soil retention:The water permeability rate is 0.1 - 1.0L/(m·s), which can not only quickly drain water but also intercept fine particles (with an interception particle size of ≥ 0.02mm), thus avoiding soil erosion.

High strength and durability:The tensile strength can reach 20 - 80 kN/m. It is resistant to seawater and chemical corrosion, adaptable to extreme climates (-50°C to +80°C), and the anti-ultraviolet aging index is > 8.

Flexible self - adapting structure:It can deform with the terrain without cracking, adapt to foundation settlement (the maximum allowable settlement rate is 10%), and perform excellently in soft soil foundations or coastal dynamic environments.

Modular construction:The size of a single geotube can be customized (diameter 0.5 - 10m, length 5 - 100m). Large - scale structures can be formed by splicing, and the construction efficiency is increased by 50% compared with traditional solutions.

Product Introduction:

Geotube is a highly efficient solidification and dewatering device based on geosynthetics. Through special weaving techniques and structural designs, it realizes functions such as sludge treatment, water purification, and slope protection in fields such as environmental protection, water conservancy, and civil engineering.

Material Composition is mainly made of high-strength polypropylene (PP) filaments through a weaving process. The material has the following properties:

Chemical Corrosion Resistance: Resistant to acids, alkalis, salt solutions, and microbial erosion, suitable for complex media such as sludge and industrial wastewater;

UV Aging Resistance: After adding anti-aging additives, it can be used for a long time in an outdoor environment (with a lifespan of 5 - 10 years);

High Tensile Strength: The warp tensile strength is ≥ 30kN/m, and the weft tensile strength is ≥ 25kN/m, capable of withstanding the internal pressure during filling.

Product Parameters:

project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

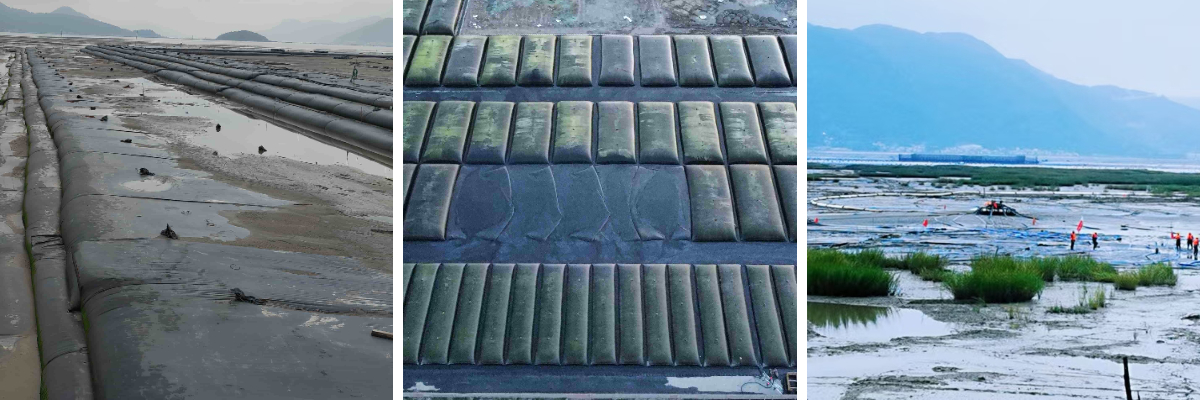

Coastal Protection and Seawall Construction:After being filled with sediment, the geotextile tube bags form a flexible structure that can adapt to foundation deformation. Meanwhile, their water permeability can reduce wave impact force. Compared with traditional concrete embankments, they have lower costs and more convenient construction.

River regulation and flood control projects:It can be quickly filled and installed to form a water - retaining structure. At the same time, it allows water to permeate, reducing the internal water pressure of the dam and improving the flood - resistance safety.

Sludge and Sewage Treatment:As a container for sludge dewatering, water is drained through the tube bag material by gravity or pressure to achieve sludge reduction.

Solid Waste Treatment and Landfill Engineering:It is used for slope reinforcement and leachate collection layer of landfills, or as a packaging container for construction waste and tailings to prevent the spread of pollutants.

Reclamation and Land Creation Projects:In coastal tidal flats and lake areas, reclamation is carried out through geotextile tube bags to form artificial land areas.

Ecological engineering:It is used for riverside ecological restoration and wetland construction. Soil is filled in the geotextile tubes and vegetation is planted to form an ecological buffer zone.

Slope Protection and Landslide Control:It is used for the protection of mountain slopes and highway slopes. The stability of slopes is increased by filling materials to prevent soil erosion.

Geotube bag technology, as an innovative technology integrating materials science, environmental engineering, and civil engineering, is developing rapidly along the direction of intelligent material upgrading, digital process transformation, and diversified expansion of application scenarios.