Geotextile under Riprap

Strengthening base protection: Prevents rocks from embedding into soft foundations or being washed away by water, preventing the riprap structure from losing stability due to base deformation, and extending the project's service life.

Improving overall impact resistance: Through its high strength and tear resistance, it disperses the impact of water on the riprap, reducing the risk of rock displacement and rolling.

Reducing project costs: Eliminating the need for additional thick layers of cushioning material, the geotextile can be directly adapted to riprap of varying particle sizes, streamlining the construction process.

Considering ecological compatibility: High-quality geotextiles offer excellent permeability, do not hinder the natural exchange of soil and water, and maintain the site's ecological cycle.

Product Introduction:

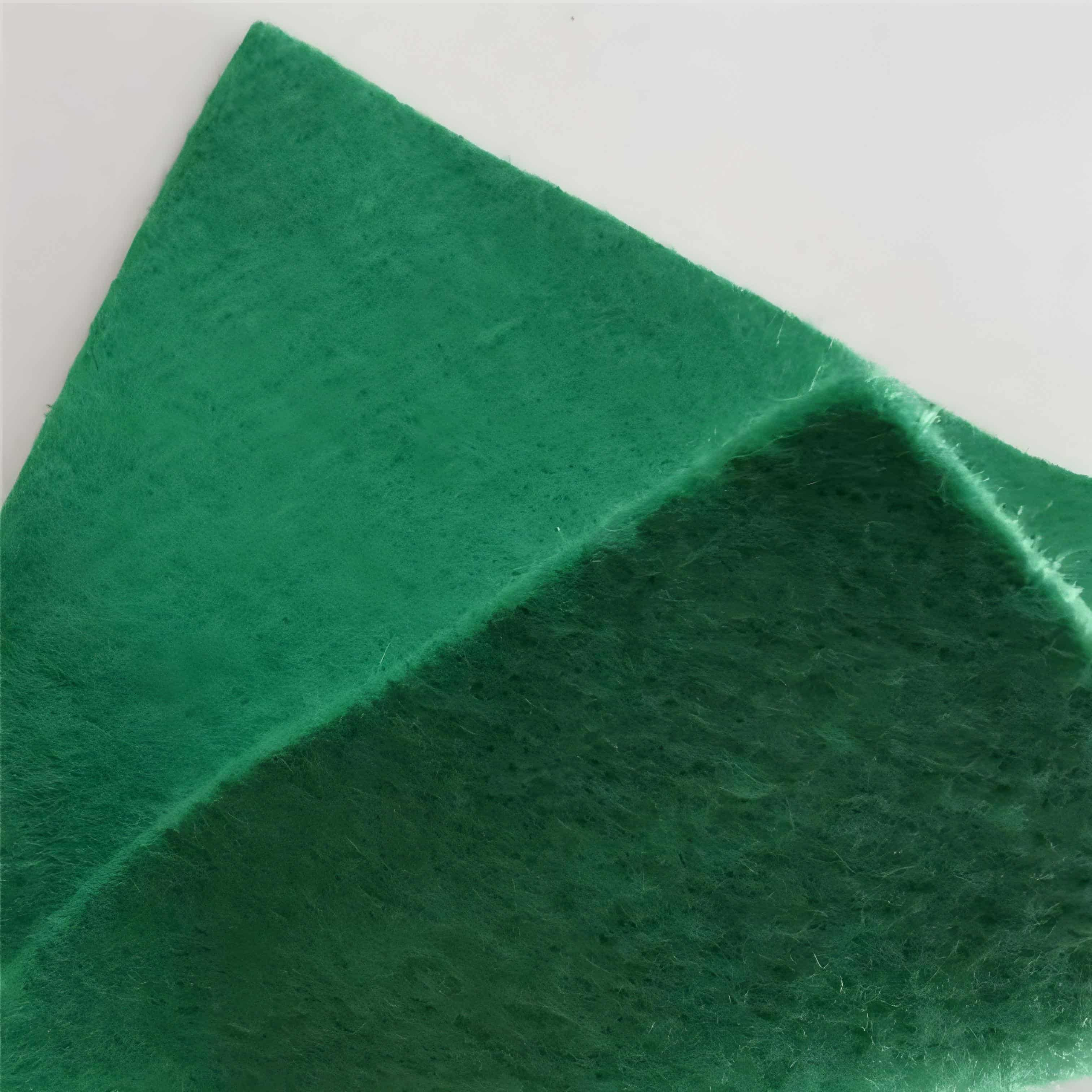

Geotextile under Riprap is a new functional material designed specifically for protection applications in water conservancy, transportation, and coastal engineering. Its core function is to serve as a critical buffer and isolation medium between the riprap layer and the underlying soil. Utilizing a high-strength fiber weaving process, this product combines excellent tear resistance and permeability. It effectively prevents riprap from embedding into soft subgrades while intercepting soil particles from being washed away by water, preventing displacement and collapse of the riprap protection structure due to deformation of the base layer, significantly improving the overall stability and service life of the project. Furthermore, its excellent permeability ensures a natural exchange of soil and water, maintaining the site's ecological cycle.

Some biodegradable versions further reduce long-term environmental residue, aligning with the concept of green engineering. In construction applications, it eliminates the need for a thick additional cushion layer and can directly accommodate riprap of varying particle sizes. This simplifies the construction process, shortens construction schedules, and reduces riprap usage and subsequent maintenance costs. It is widely applicable to a variety of protection projects, including river bank protection, port terminals, highway slopes, and reservoir embankments, providing dual guarantees for project safety and cost control.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

I. Water Conservancy Engineering

1. Riverbank Protection

During riverbank protection construction in natural or artificially renovated rivers, long-term erosion can easily lead to soil loss on the bank slopes. While riprap can directly resist water impact, it can easily embed into soft bank slopes or cause collapse due to soil hollowing. Geotextile under Riprap, applied between the riprap layer and the bank slope soil, effectively isolates the two. It prevents riprap from sinking into the soft soil, ensuring the structural integrity of the riprap layer and its continued erosion resistance. It also intercepts bank slope soil particles, preventing them from being lost with water and causing bank deformation. This product is particularly effective in rivers with frequent seasonal flooding, as it can withstand the transient external forces of flooding, reduce the frequency of bank protection maintenance, and ensure safe flow and bank slope stability.

2. Reservoir and Dam Protection

The upstream slopes of reservoir and dam embankments are constantly impacted by water level fluctuations and wave impacts, making the dam soil susceptible to seepage deformation or localized erosion. During riprap protection construction on the flood-facing slopes of dams, laying Geotextile under Riprap creates a three-layer protection system: soil - geotextile - riprap. The high permeability of the geotextile not only drains excess water from the dam body, preventing risks such as pipe bursts and soil flow caused by excessive osmotic pressure, but also prevents riprap from compressing and damaging the dam soil. Furthermore, its tear resistance cushions the impact of waves on the riprap, preventing its displacement and damage to the embankment's protective layer, providing a critical guarantee for the long-term safe operation of reservoir dams.

II. Transportation Engineering

1. Highway Slope Protection

Highway slopes, especially those in mountainous areas, are often subject to risks such as rainwater erosion and landslides. Riprap is a commonly used slope reinforcement method, but the soil on these slopes is often loose, making the riprap susceptible to sinking or sliding with the soil. The use of geotextile under riprap in highway slope riprap protection can restrain the slope soil through its high strength, reducing lateral displacement. It also isolates the riprap from the loose soil, preventing it from embedding into the soil and causing the protective layer to fail. Furthermore, in rainy areas, the permeability of geotextiles can accelerate the infiltration and drainage of rainwater from the slopes, preventing accumulation of rainwater within the slopes and causing landslides, thereby ensuring highway safety and reducing slope maintenance costs.

2. Railway Subgrade Protection Projects

During operation, railway subgrades are susceptible to deformation and slope collapse due to the influence of train loads, rainwater erosion, and geological subsidence. Geotextile under Riprap plays a vital role in riprap protection for roadbed slopes or abutment slopes. First, it isolates the riprap from the roadbed filler, preventing uneven settlement caused by compaction. Second, it intercepts filler particles, preventing erosion and loss due to rainwater, thereby maintaining the stability of the roadbed structure. Third, its excellent flexibility allows it to adapt to minor roadbed settlements, preventing cracks in the protective layer caused by settlement and ensuring railway traffic safety.

III. Coastal and Port Engineering

1. Coastal Beach Protection

Coastal areas are subject to the constant action of tides and waves, making beaches susceptible to erosion. Riprap beach protection is a crucial measure for protecting coastal landforms. However, coastal soils are mostly sandy, and riprap can easily sink into the sand or be displaced by waves. Once laid, Geotextile under Riprap forms a solid isolation layer. It prevents riprap from embedding into the sandy soil, ensuring the riprap layer's resistance to waves. It also intercepts sand particles, preventing tidal loss and maintaining the integrity of the coastal beach. The product's salt corrosion resistance also allows it to adapt to seawater environments, extending the service life of protective projects and protecting coastal ecosystems and facilities.

2. Port and Wharf Protection Projects

Port and wharf breakwaters and quay walls are constantly impacted by waves and ship impacts, making the riprap layer susceptible to damage. The use of Geotextile under Riprap in port projects can enhance the stability of the riprap layer. During breakwater construction, the geotextile disperses the impact of waves on the riprap, reducing its displacement and ensuring the breakwater's protective effect on the port. In quay wall protection, its isolation function prevents erosion of the quay wall soil, preventing tilting and collapse due to soil hollowing. Furthermore, the product's aging resistance allows it to adapt to the complex marine environment of ports, reducing maintenance costs and ensuring normal port operations.

Geotextile under Riprap is a functional protective material between the riprap layer and the soil, offering four core properties: isolation and protection, impact resistance and buffering, water permeability and adaptability, and environmental compatibility. Its applications span water conservancy (river bank protection, reservoir dams), transportation (highway slopes, railway subgrades), and coastal ports (beach protection, wharf protection). It improves project stability, reduces maintenance and initial investment, and is a key supporting material for a wide range of protective projects.