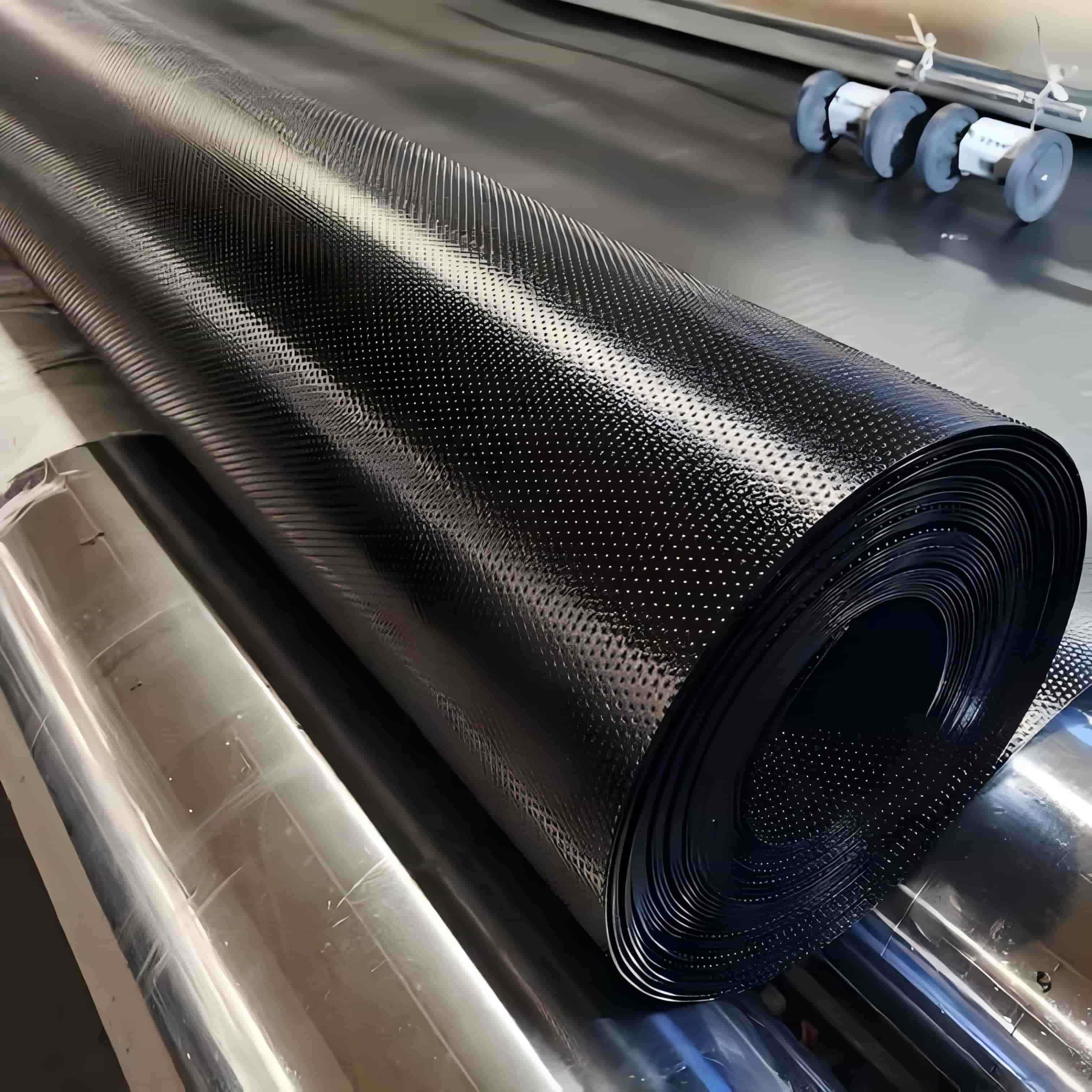

Impermeable Geomembrane

1. Strong anti-seepage effect: The molecular structure is dense and the permeability coefficient is extremely low, which can effectively block liquid leakage and ensure the sealing effect of the project.

2. Good weather resistance: resistant to ultraviolet rays, high and low temperatures, adaptable to different climatic environments, and extending the service life of the project.

3. Convenient construction: flexible texture, light weight, high welding and splicing efficiency, can quickly adapt to complex terrain laying.

4. Widely applicable: It is versatile in various fields such as water conservancy, municipal engineering, and environmental protection, and has both corrosion resistance and puncture resistance.

Products Introduction:

Impermeable geomembrane is a synthetic membrane lining or barrier material with extremely low permeability. It is mainly made of high molecular weight polymers, such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), etc. Taking HDPE geomembrane as an example, it is composed of HDPE resin to form plastic rolls. HDPE, as a highly crystalline and non-polar thermoplastic resin, endows geomembrane with many excellent characteristics. The original appearance of the geomembrane is milky white, with a certain degree of semi transparency in the thin section. It is non hygroscopic and has good waterproof steam performance.

Product Features:

1. Excellent anti-seepage performance: It has an anti-seepage effect that ordinary waterproof materials cannot match. Taking HDPE geomembrane as an example, its anti-seepage coefficient is extremely low, with a water vapor permeability coefficient K<=1.0 * 10-13g.cm/c cm2. spa, which can effectively prevent the leakage of liquids and gases, efficiently cope with expansion or contraction of the base surface, effectively overcome uneven settlement of the base surface, and ensure sealing effect.

2. Good chemical stability: It can withstand high and low temperatures, and has excellent corrosion resistance to more than 80 strong acid and alkali chemical media such as asphalt, oil, tar, acid, alkali, salt, etc. Therefore, it is widely used in sewage treatment tanks, chemical reaction tanks, landfills and other scenarios that require high chemical stability.

3. Excellent aging resistance: It has excellent aging resistance, UV resistance, and decomposition resistance. Even if it is exposed, the service life of the material can reach 50-70 years, providing a reliable material guarantee for long-term environmental seepage prevention projects.

4. Anti puncture and high mechanical strength: It has excellent anti puncture ability, can resist most plant roots, and has good mechanical strength. For example, the fracture tensile strength of HDPE geomembrane reaches 28MPa, with a fracture elongation of 700%, and can withstand large external forces. The fracture tensile strength of HDPE geomembrane reaches 28MPa, with a fracture elongation of 700%, and can withstand large external forces such as pulling and impact.

5. Convenient and cost-effective construction: There are multiple specifications and laying forms that can flexibly meet the anti-seepage needs of different projects. Hot melt welding is used, with high weld strength, convenient construction, and fast speed. Moreover, the anti-seepage effect has been improved through new technologies, and the production process is more scientific and efficient, resulting in lower product costs compared to traditional waterproof materials. Generally, the cost can be saved by about 50% after being adopted in engineering projects.

6. Environmentally friendly and non-toxic: The production materials are all non-toxic and environmentally friendly, and the anti-seepage principle is based on ordinary physical changes. During use, no harmful substances are produced, making it an ideal choice for environmental engineering, breeding sites, drinking water tanks, and other projects.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. In the field of environmental protection and sanitation: In domestic waste landfills, it can effectively prevent soil and groundwater pollution caused by leachate leakage; In sewage treatment plants, it is used for anti-seepage of water tanks and channels to ensure that sewage meets the standards for treatment; It also plays a key role in preventing seepage in power plant regulating pools, hospital solid waste treatment sites, etc.

2. Water conservancy engineering: it is widely used in seepage prevention, leakage stoppage and reinforcement of Rivers and Lakes, reservoirs and dams, which can enhance the stability of dams; Canal seepage prevention can reduce water resource loss; In vertical core wall and slope protection engineering, geomembranes can improve the anti-seepage and protective performance of water conservancy facilities.

3. In the field of municipal engineering, the foundation reinforcement of highways and the anti-seepage of culverts can ensure the stability of road structures; The underground engineering of subways and buildings, as well as the anti-seepage of planted roofs and rooftop gardens, can prevent leakage from damaging the building structure and provide good conditions for greening; The use of geomembrane lining in sewage pipelines can enhance their anti-seepage and corrosion resistance capabilities.

4. Landscape field: In projects such as rooftop gardens, artificial lakes, rivers, reservoirs, and golf courses, the bottom lining and slope protection of ponds can not only achieve anti-seepage function, but also create beautiful landscapes and protect green lawns from water damage.

5. Petrochemical industry field: anti-seepage of oil storage tanks in chemical plants, refineries, and gas stations can prevent oil leakage; The inner lining and secondary lining of chemical reaction tanks and sedimentation tanks are made of geomembranes, which can ensure the safe and stable operation of chemical production.

6. Mining field: washing tanks, heap leaching tanks, ash yards, dissolution tanks, sedimentation tanks, storage yards, tailings bottom lining anti-seepage, etc. can prevent harmful substances from leaking during mineral processing and protect the surrounding ecological environment.

7. In the field of agriculture and aquaculture, anti-seepage measures for reservoirs, drinking water tanks, water storage ponds, and irrigation systems can improve water resource utilization efficiency; In agricultural farming (such as septic tanks in pig farms) and aquaculture (such as lining fish ponds, shrimp ponds, sea cucumber enclosures, etc.), geomembranes can maintain water cleanliness and promote the development of the aquaculture industry.

8. In the field of salt industry, geomembranes can effectively prevent brine leakage and improve the production efficiency of salt industry, including salt field crystallization pool, brine pool covering, salt film, and salt pool plastic film.

Impermeable geomembrane, as a high-performance anti-seepage material, has many advantages such as excellent anti-seepage performance, good chemical stability, and excellent aging resistance. It has indispensable applications in many fields such as environmental protection and sanitation, water conservancy engineering, municipal engineering, landscape architecture, petrochemicals, mining, agriculture and aquaculture, salt industry, etc. It can not only ensure the stable operation of various projects, but also play an important role in environmental protection, resource conservation, and other aspects. It is a highly valuable material in modern engineering construction.