Geo Fabric Textile

1. Multi functional, versatile material:The core advantage lies in the integration of multiple functions such as isolation, filtration, drainage, reinforcement, and protection. One material can simultaneously solve multiple engineering problems.

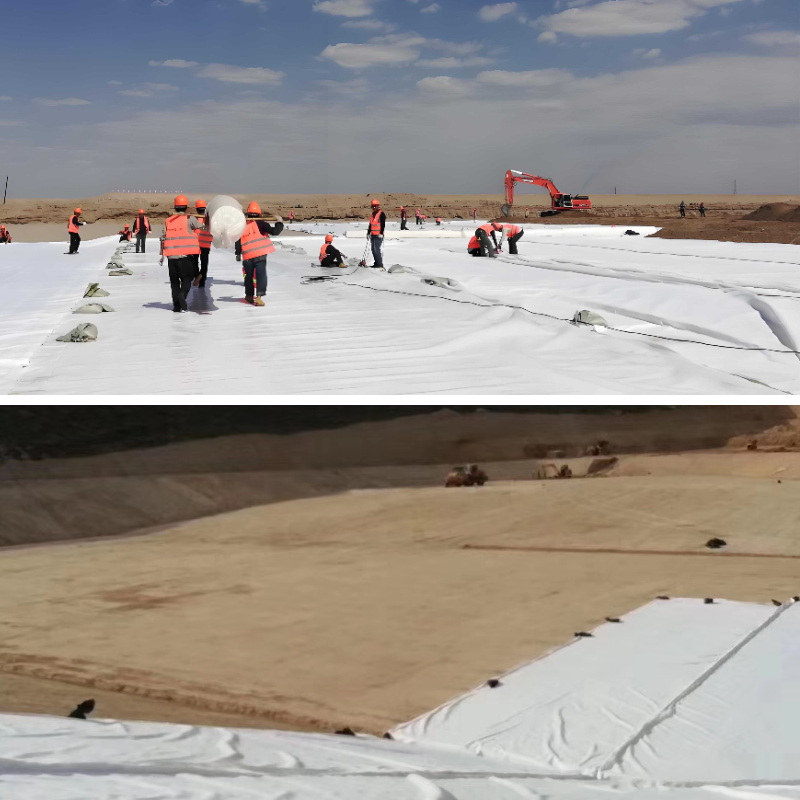

2. Easy construction and high efficiency:The material is lightweight, supplied in rolls, easy to cut, transport, and lay, greatly simplifying the construction process and shortening the construction period.

3. Reduce overall costs and highlight economic benefits:It can replace traditional materials such as sand, stone, and gravel in large quantities, saving material costs, transportation costs, and labor costs, and reducing overall project costs.

4. Corrosion resistance and long service life:Made of synthetic fibers, it is resistant to acid and alkali, biological and chemical corrosion, and can maintain its performance in soil and water for a long time, with a long service life.

Product Introduction:

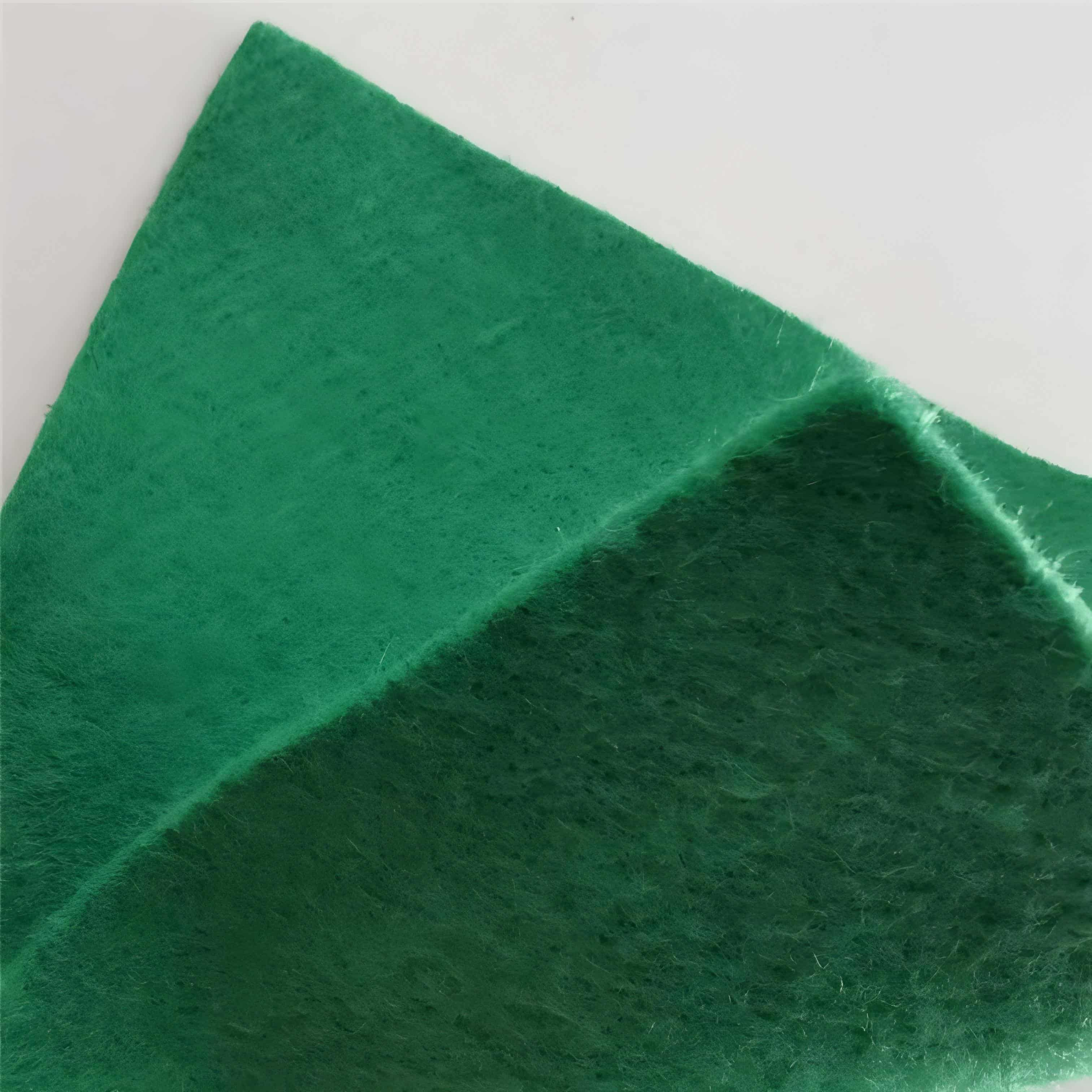

Geo Fabric Textile is a permeable geosynthetic material made of synthetic fibers through needle punching or weaving.

Here is a detailed introduction to it:

Classification

1. Long filament spun clay geotextile: also known as polyester geotextile, has characteristics such as high strength, low elongation, durability, and corrosion resistance.

2. Short fiber needle punched geotextile: Made from polyester curled short fibers with a fiber fineness of 6-12 deniers and a length of 54-64mm as raw materials, it is produced through non-woven production equipment processes such as opening, combing, shuffling, mesh laying, and needle punching.

3. Woven geotextile: made from polypropylene and acrylic flat yarn, it has good tensile strength and tear resistance.

4. Woven geotextile: Using high-strength industrial synthetic fibers such as polypropylene, polyester, and nylon as raw materials, it is woven into a regular interwoven structure with high comprehensive bearing capacity.

5. Burnt geotextile: including non-woven geotextile base and sintered layer, which not only achieves surface agglomeration but also maintains the original properties of non-woven geotextile, specially designed and developed for anti slip design of slopes in garbage sanitary landfills.

Feature

1. Superior physical performance: lightweight, generally 4-6 meters wide, 50-100 meters long, and up to 9 meters wide; The mass per unit area is 100-1000g/m ². It has high strength and uses plastic fibers to maintain sufficient strength and elongation in both dry and wet conditions.

2. Good chemical stability: corrosion-resistant, able to resist corrosion for a long time in soil and water of different pH levels; Good resistance to microorganisms and insect infestations without damage.

3. Good water permeability: There are gaps between the fibers, which have good water permeability and can allow water flow to pass through while effectively intercepting soil particles.

4. Convenient construction: The material is light, flexible, and easy to transport, lay, and construct.

Effect

1. Isolation: Isolate building materials with different physical properties to prevent material loss and mixing, maintain overall structure and function, and enhance the load-bearing capacity of the structure.

2. Filtration: When water flows from the fine soil layer into the coarse soil layer, its permeability and air permeability are utilized to allow water flow through, intercept soil particles, etc., and maintain the stability of soil and water engineering.

3. Drainage: It has good water conductivity and can form drainage channels inside the soil to discharge excess liquids and gases.

4. Reinforcement: Enhance the tensile strength and deformation resistance of soil, improve soil quality, and strengthen the stability of building structures.

5. Protection: When water flows on the soil, it can diffuse, transmit or decompose concentrated stress, preventing the soil from being damaged by external forces and protecting the soil.

6. Anti puncture: Combined with geomembrane to form a composite waterproof and anti-seepage material, it plays a role in preventing puncture.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation engineering field

Traffic engineering has extremely high requirements for roadbed stability and pavement durability, and the addition of geotextiles can effectively improve the quality of the project

Railway Engineering:

Used for reinforcing railway subgrade, enhancing the shear strength and integrity of the subgrade soil, reducing the settlement and deformation of the subgrade during train operation, especially in soft soil foundation sections, the effect is significant.

Laying geotextile between the track and the roadbed serves as an isolation measure to prevent mixing of track fill and roadbed soil. It also has a filtering function to prevent fine particle soil from blocking drainage channels.

Highway engineering:

When building a new highway, laying geotextile between the roadbed and the base layer can isolate materials of different particle sizes, prevent the base layer material from infiltrating the roadbed soil, and ensure the stability of the base layer structure.

In highway pavement maintenance, it can be used to repair pavement cracks. Laying geotextile between the old pavement and the new surface layer can effectively suppress the reflection of cracks and extend the service life of the pavement.

For highways on soft soil foundations, using geotextile reinforcement can disperse loads, improve foundation bearing capacity, and reduce uneven settlement of the roadbed.

Airport Engineering:

In the foundation treatment of airport runways and aprons, geotextiles can enhance the overall integrity and deformation resistance of the foundation, and resist the huge impact force during aircraft takeoff and landing.

Lay geotextile between the base and surface layers of the runway to filter and drain water, preventing rainwater from seeping into the foundation and causing damage.

2. Water conservancy engineering field

In hydraulic engineering, geotextiles play a key role in anti-seepage, drainage, protection, and other aspects:

Dam engineering:

Geotextile is used for slope protection of dams. When water flows over the dam, it can disperse the concentrated stress of the water flow, reduce the erosion of the dam soil, and protect the safety of the dam.

During the process of dam filling, the isolation effect of geotextile is utilized to separate fillers of different properties, avoiding the impact of material mixing on the structural stability of the dam.

Reservoir and Channel Engineering:

Laying geotextile at the bottom of the reservoir can play a filtering and drainage role, preventing soil particles from being carried away by water flow, and at the same time, draining the seepage at the bottom of the reservoir to ensure its normal operation.

Laying geotextile on the slopes and bottom of irrigation channels can reduce the erosion of water flow on the channels, extend the service life of the channels, and improve the water delivery efficiency of the channels.

River regulation project:

After dredging the river, laying geotextile on the bank slope of the river and covering it with soil material for vegetation planting can prevent soil erosion on the bank slope and improve the ecological environment of the river.

Reinforcement is used for river bank protection to enhance the stability of the bank protection structure and resist the impact of water flow.

3. Environmental engineering field

In environmental engineering, geotextiles play a prominent role in preventing pollution from spreading and ensuring ecological safety

Landfill site:

Combined with geomembrane to form a composite anti-seepage system. Geotextile is located above the geomembrane to prevent punctures and prevent sharp objects in the garbage from puncturing the geomembrane, ensuring anti-seepage effect and preventing garbage leachate from contaminating the soil and groundwater.

In the drainage system of the landfill, geotextile serves as a filter layer, allowing leachate to pass through while intercepting garbage particles to prevent blockages in the drainage pipes.

Sewage treatment project:

Geotextile can be used as a filtering material in sedimentation tanks, filtration tanks and other facilities of sewage treatment plants to separate suspended particles in sewage and improve sewage treatment efficiency.

The anti-seepage protective layer used for sewage tanks protects the anti-seepage membrane from damage.

Solid waste disposal site:

When dealing with solid waste such as industrial waste and tailings, geotextiles can isolate the waste from the surrounding soil to prevent harmful substances from infiltrating and polluting the environment. At the same time, the accumulated water in the site can be drained through drainage to avoid the loss of waste due to long-term immersion.

4. In the field of architecture and municipal engineering

Building foundation engineering:

In the treatment of building foundations, for soft soil foundations, geotextile reinforcement can be used to increase the bearing capacity of the foundation, reduce foundation settlement, and ensure the structural safety of the building.

Used for isolation between foundations, preventing the mixing of foundation materials and soil, and ensuring the construction quality of foundations.

Municipal drainage engineering:

Laying geotextile around urban underground drainage pipes can play a filtering and drainage role, preventing soil particles from entering the pipes and causing blockages, while also introducing groundwater into the drainage pipes for discharge.

In sponge city facilities such as rain gardens and infiltration wells, geotextiles can be used as filtering layers to purify rainwater and promote rainwater infiltration.

Underground engineering:

In the construction of underground projects such as subways and tunnels, geotextiles can be used for drainage and filtration between initial support and secondary lining, to discharge seepage from the surrounding rock and ensure the dryness and stability of the tunnel structure.

In the construction of underground continuous walls, geotextiles can protect the walls and prevent the loss of soil particles on the outside of the walls.

In short, geotextiles play an indispensable role in various engineering projects due to their diverse functions and excellent performance, providing important guarantees for the safety, stability, and durability of the projects. With the continuous development of engineering technology, its application fields are still expanding and deepening.