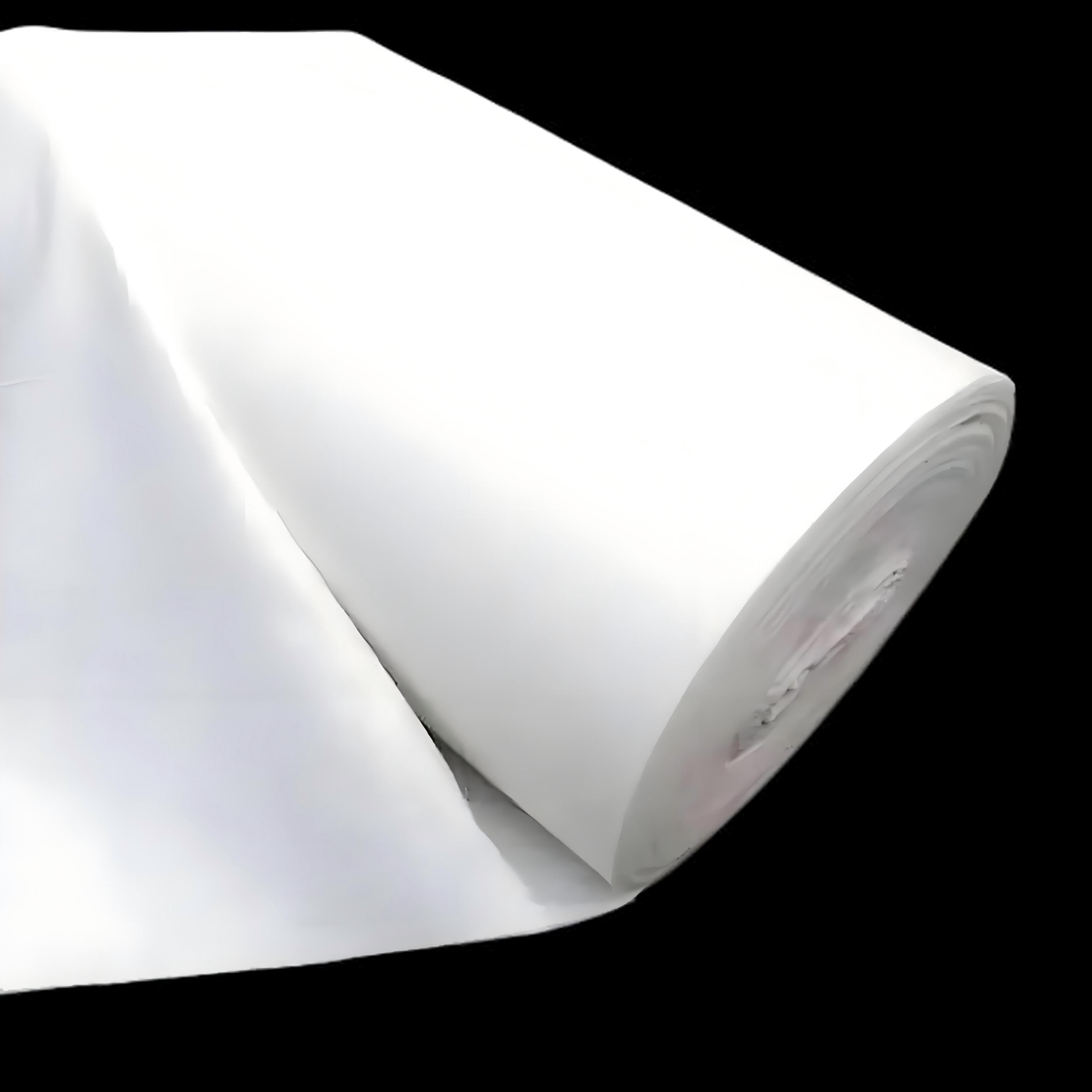

Cushion Geotextile

1. Excellent buffering protection: It can effectively disperse external impact, provide flexible buffering for soil, pipelines, etc., reduce damage caused by compression and friction, and improve engineering stability.

2. Excellent permeability: It combines the characteristics of blocking impurities and permeability, preventing soil particle loss while ensuring normal water infiltration and maintaining hydrological balance in the project area.

3. Strong and durable: Made of high-strength materials, it is tear resistant, acid and alkali resistant, and can adapt to complex geological environments, extending the service life of the project.

4. Convenient and efficient construction: The material is lightweight and easy to cut and lay, which can quickly adapt to different construction scenarios, reduce installation difficulty, and save labor and time costs.

Products Introduction:

Cushion Geotextile is a new type of geosynthetic material designed specifically for engineering protection and cushioning needs. It is made of polymer as the core material and processed through special weaving or non-woven processes, combining flexible structure and high strength performance. As a key auxiliary material in engineering construction, its core function is to provide buffering protection, infiltration regulation, and structural enhancement for soil, pipelines, roadbeds, and other structures in various infrastructure projects through its structural characteristics. It is an indispensable and important material in modern civil engineering, water conservancy engineering, transportation construction, and other fields.

Product Features:

1. Excellent cushioning and shock absorption performance: Cushion Geotextile has a unique fluffy fiber structure or multi-layer composite design, which can effectively disperse external load impacts through elastic deformation between fibers. When subjected to external forces such as vehicle crushing, soil settlement, or mechanical vibration, concentrated stress can be converted into dispersed force, significantly reducing the stress intensity on the surface and inside of the structure, reducing problems such as cracking and deformation caused by long-term impact, and providing long-term protection for the foundation structure.

2. Efficient penetration and barrier balance ability: The material itself has a uniform microporous structure, which allows for normal penetration of water and gas while accurately blocking impurities such as soil particles and sand. This feature not only avoids soil erosion caused by water flow erosion, ensures soil and water stability in the engineering area, but also prevents poor drainage caused by pore blockage, maintaining the hydrological cycle balance of the engineering environment.

3. Super durability and environmental adaptability: High molecular materials with strong weather resistance (such as polypropylene, polyester, etc.) are selected, and after special processing, they have excellent ultraviolet resistance, acid and alkali corrosion resistance, and aging resistance. Even in complex and harsh geological and climatic environments such as high temperature, severe cold, and humidity, it can maintain stable physical properties and structural integrity, with a service life of several decades.

4. Flexible and convenient construction characteristics: The product has a lightweight texture, much lower weight than traditional protective materials, and has good flexibility and extensibility. It can be cut and spliced according to the actual needs of the project, easily adapting to different terrain contours (such as slopes, curved surfaces, irregular foundations, etc.). The laying process does not require complex professional equipment, and can be quickly operated manually or mechanically, greatly reducing the construction period and lowering the installation cost of the project.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

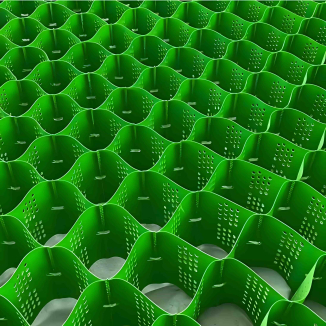

1. In the field of transportation engineering, it is widely used as a roadbed buffer layer for highways and railways, which can effectively absorb the vibration loads generated by vehicle travel, reduce roadbed settlement and deformation; In tunnel engineering, it can serve as a buffer isolation layer between the lining and the surrounding rock, protecting the lining structure from direct impact of rock pressure.

2. Water conservancy and municipal engineering: used for slope protection of rivers and channels, playing a role in buffering water flow erosion and preventing soil erosion; In projects such as sewage treatment plants and landfills, it can serve as an auxiliary buffer layer for the anti-seepage system, protecting the anti-seepage membrane from sharp object punctures and enhancing the drainage performance of the system.

3. Architecture and Geological Engineering: In the treatment of building foundations, it serves as a cushioning material between the foundation and the cushion layer, evenly dispersing the load on the upper structure; In geological disaster prevention and control (such as landslide and debris flow control), it can be laid on the inner side of the protective structure to buffer the impact force generated by soil sliding and improve the stability of the protective system.

4. Mining and Energy Engineering: In the construction of tailings ponds for mining, a buffering and anti-seepage layer is used for the dam body to reduce the erosion of tailings on the dam body; In the foundation engineering of wind and photovoltaic power plants, as a foundation buffer material, it protects the foundation structure from damage caused by surface stress.

Cushion Geotextile, as a high-performance geosynthetic material, plays an irreplaceable role in many engineering fields such as transportation, water conservancy, construction, mining, etc., thanks to its outstanding core advantages of buffering, shock absorption, permeability adjustment, durability, corrosion resistance, and convenient construction. It can not only effectively improve the stability and safety of engineering structures, extend the service life of the project, but also bring significant economic and social benefits to the project by simplifying the construction process and reducing maintenance costs. Whether dealing with complex geological environments or meeting diverse engineering needs, Cushion Geotextile is an ideal choice for achieving efficient and long-term protection in modern engineering construction.