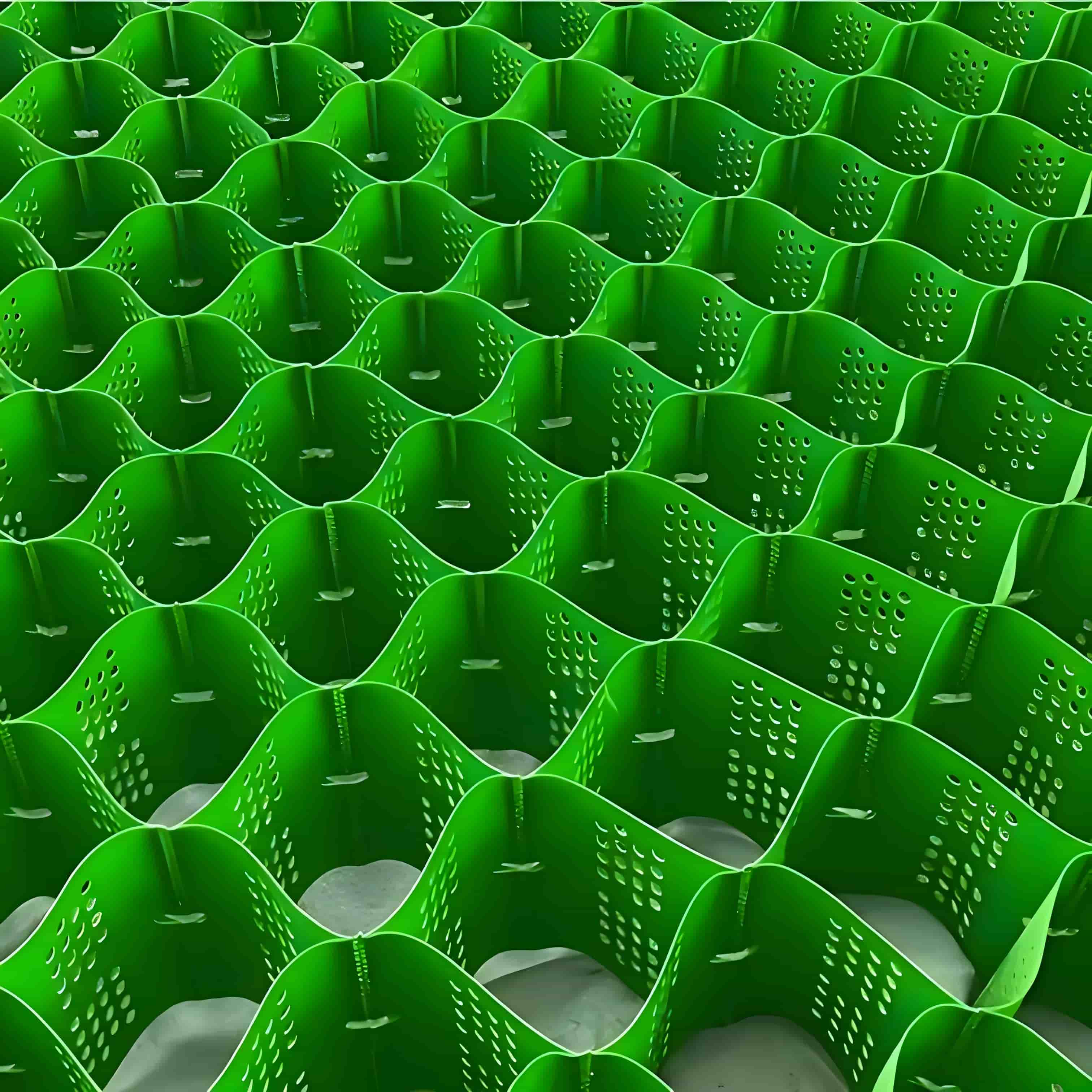

Geocell Fabric

1.High Strength and Load-Bearing Capacity

It exhibits exceptional tensile, compressive, and shear resistance, enabling it to withstand significant loads.

2.Superior Durability and Environmental Adaptability

Geocells resist chemical corrosion, UV degradation, and aging, ensuring stable performance during prolonged use in harsh environments.

3.Three-Dimensional Reinforcement Mechanism

The honeycomb structure imposes lateral confinement on the filled materials, forming a composite system that markedly enhances shear strength, overall stiffness, and structural stability.

Product Introduction:

Geocell Fabric is a three-dimensional net-like structure formed by welding or riveting high-strength polymeric materials (such as high-density polyethylene, HDPE; polypropylene, PP, etc.). Its unique honeycomb or cellular design endows it with significant reinforcement and stabilization effects in civil engineering applications. The geocell can be collapsed and folded for convenient transportation and storage. During construction, it is unfolded and filled with materials such as soil, rocks, or concrete to form a structural body with high lateral restraint and significant stiffness.

Flexible Adaptation: Accommodates uneven settlement and terrain variations, reducing cracks and collapses.

Permeability: The cellular structure allows free water drainage, preventing water accumulation issues.

Easy Installation: Modular design allows for folded transportation and quick on-site deployment with direct filling, saving time and costs.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Soft Soil Foundation Treatment

Used for reinforcing soft soil foundations to enhance bearing capacity and reduce settlement.

2.Slope Protection and Reinforcement

Applied to stabilize and protect slopes, preventing landslides and collapses while enabling integration with vegetation for ecological greening.

3.Retaining Walls and Supporting Structures

Serves as an alternative to traditional gravity-type retaining walls, reducing structural self-weight and simplifying construction.

4.River Channel Regulation and Bank Protection

Utilized for slope and bank protection in river channels to prevent erosion by water flow and maintain bank stability.

5.Engineering in Desert and Wind-Sand Environments

Employed in desert regions for subgrade reinforcement to resist wind-sand erosion and improve road stability.

6.Railway and Highway Subgrade Reinforcement

Applied to reinforce railway and highway subgrades, minimizing settlement and extending service life.

Geocell Fabric, with its characteristics of "low cost, high efficiency, and easy construction", has become an important material in highway engineering to solve complex geological problems and improve engineering durability. Especially in the current context where the requirements for ecological protection and sustainable development are increasingly high, its application prospects are even broader.