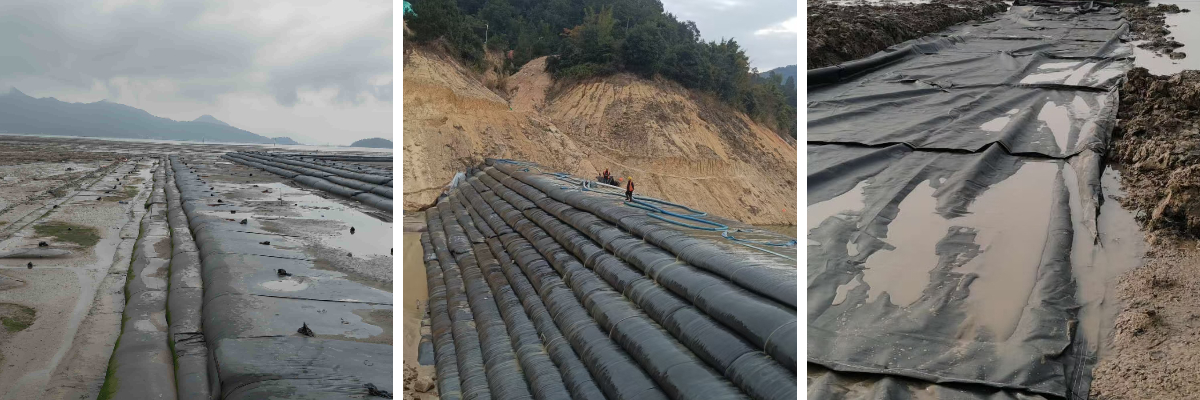

Dewatering Bags for Dredging

1. Fast construction speed: Using hydraulic filling with high mechanization can shorten the construction period.

2. Low cost: Local materials can be used, and local silt or sand can be used for construction, reducing the transportation cost of soil or sand and gravel.

3. Good environmental performance: The construction area is small and can be used for the treatment of river, lake, sea sludge, municipal sludge, industrial sludge, etc. It can filter the water in high moisture polluted soil, retain pollutants, and is conducive to environmental protection.

Product Introduction:

Dewatering Bags for Dredging are large tubular bag made of high-strength and durable geotextile (usually polypropylene or polyester material), which is a registered trademark of a certain brand but often used as a generic name.

The core working principle is:

Fill the bag with mud (usually a mixture of water and sediment, silt, or other fine particulate matter) through a pumping device. The special structure of geotextiles allows water to quickly seep out through tiny pores under pressure (filtration/dehydration effect), while solid particles are effectively trapped and contained in bags. Over time, through layer by layer filling and dehydration consolidation, a sturdy and stable soil structure or solid material that has undergone dehydration treatment is ultimately formed.

Feature

1. Permeable and impermeable soil: This is its most core technical feature. The aperture of geotextiles is carefully designed to allow only water to pass through while retaining solid particles.

2. High strength: The geotextile used has extremely high tensile strength and puncture resistance, and can withstand the enormous pressure generated by filling and stacking.

3. Flexible structure: Unlike concrete or stone, it is not rigid and can disperse stress through deformation, with good seismic performance.

4. Stackability: The dehydrated and consolidated geotextile bags have high stability and can be stacked layer by layer like bricks to form larger structures.

5. Visual construction: The construction process and quality control are relatively intuitive, and the filling degree and structural form are easy to observe and adjust.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Water conservancy and coastal engineering

This is the earliest and most classic application field of geotextile bags, mainly used to replace traditional stone and concrete structures.

Breakwaters and Offshore Dikes:

Application description: Large geotextile bags are placed side by side or stacked layer by layer to form a core barrier underwater or exposed to the water surface, which is used to weaken wave energy and protect coastlines, ports, or aquaculture areas from erosion.

Advantages: More material efficient than traditional stone throwing structures, lower requirements for foundation bearing capacity, and faster construction speed.

Revetment and Embankment Protection:

Application description: Used to reinforce the foot of a dam (to prevent erosion) or slope surface. For example, laying pipe bags as a protective surface on the upstream slope of the riverbank and using them as a pressure platform on the downstream slope to prevent collapse.

Advantages: Flexible structures can better adapt to embankment settlement and have good overall integrity.

Beach Nourishing and Shoreline Restoration:

Application description: Laying geotextile bags parallel to the coastline in nearshore areas, as "artificial reefs" or submerged embankments, can effectively promote the breaking of waves before reaching the main beach, thereby slowing down the loss of sand and even causing sediment to accumulate behind the bag structure, achieving the goal of beach cultivation.

Advantages: Eco friendly, can integrate with the natural environment.

2. Environmental Engineering and Dredging Industry

This is currently the most widely used and rapidly developing field, mainly used to solve the problem of mud dewatering treatment.

Dredged Sludge Dewatering:

Application description: During the dredging process of rivers, lakes, and ports, a large amount of high water content mud will be generated. Pump these mud into a closed geotextile bag yard, and after the water seeps out, the volume of sludge is significantly reduced (with a reduction rate of over 80%), forming a soil with high solid content. The treated clean water can be discharged back to the standard, while the dry mud is easy to transport.

Advantages: Large processing capacity, low cost, and high efficiency.

Contaminated Sediment Containment:

Application description: For sediment containing harmful substances such as heavy metals and organic pollutants, geotextile bags can effectively seal the pollutants inside the bag while dehydrating, preventing them from spreading in the water and causing secondary pollution. This provides a safe and stable way for subsequent safe disposal or on-site storage.

Advantages: With high environmental safety, it is one of the best feasible technologies for treating polluted sediment.

Industrial and Municipal Sludge Treatment:

Application description: Treatment of industrial wastewater (such as paper mills, chemical plants) and sludge generated by sewage treatment plants. The principle is the same as dredging sludge treatment, achieving sludge reduction and stabilization.

Advantage: It can replace some expensive mechanical dehydration equipment and reduce processing costs.

Tailings Management:

Application description: Used for dewatering and storage of mine tailings. Fill the fine tailings slurry generated after beneficiation into large pipe bags to accelerate its consolidation, reduce the storage capacity demand and dam failure risk of the tailings pond.

Advantage: Improve the stability and safety of tailings storage.

3. Dewatering and Cofferdam Applications

Temporary Cofferdams:

Application description: In hydraulic engineering construction, temporary water retaining structures need to be constructed for dry land operations. Quickly filled geotextile bags can efficiently form a temporary cofferdam.

Advantages: Extremely fast construction, can be dismantled and recycled after completion, and materials can be reused.

4. Agriculture and Aquaculture

Pond Slope Protection:

Application description: Used to reinforce the slope of aquaculture ponds, prevent soil erosion and collapse.

Advantages: Low cost, good durability.

Irrigation Channel Linings:

Application description: Used for protecting the bottom and slope of channels, reducing leakage and water flow erosion.

Advantage: Strong adaptability to foundation deformation.

The application of geotextile bags essentially embodies their three core functions of dehydration, containment, and reinforcement. From defending coastlines to managing rivers and lakes, from treating industrial pollution to supporting agricultural production, it provides an efficient, economical, and environmentally friendly solution to modern engineering and environmental challenges with its unique advantages.