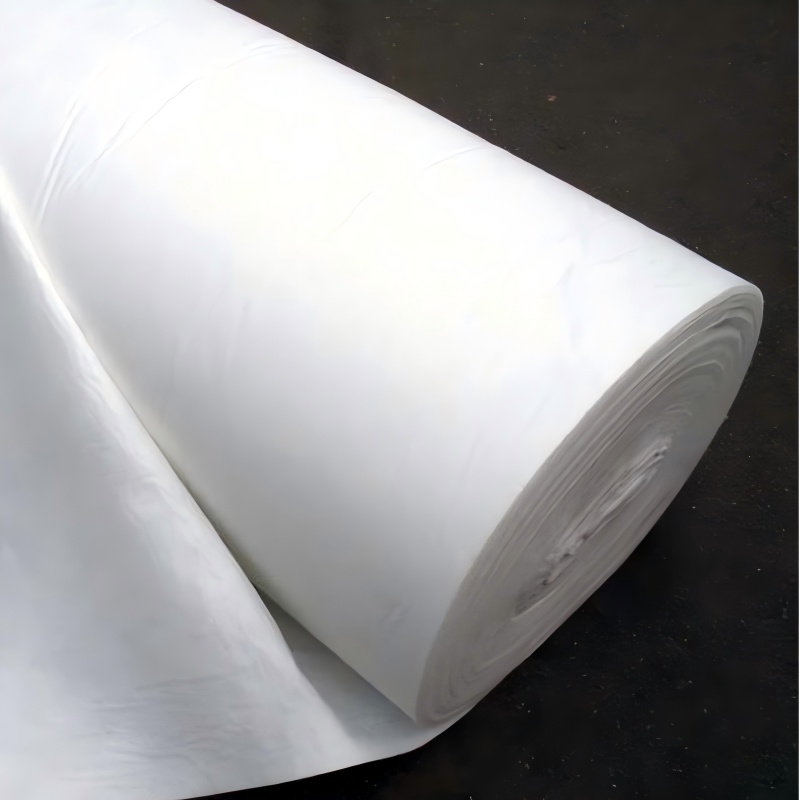

Geofabric Cloth

1.Filtering: Retain soil particles, remove moisture, prevent loss and blockage.

2.Isolation: Separate different materials (such as soil and gravel) to ensure structural stability.

3.Reinforcement: By relying on its own tensile strength, it enhances the load-bearing capacity of the soil and prevents collapse and settlement.

4.Protection: Buffer impact (such as water flow and gravel abrasion), extend the service life of the project.

Product Introduction

Basic attributes: Definition and essential characteristics

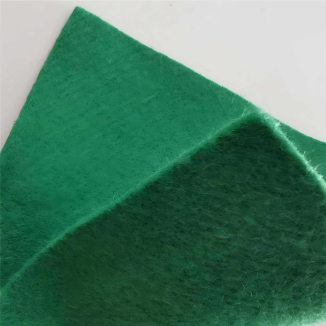

1.Geofabric Cloth mainly use high molecular weight synthetic fibers (such as polypropylene, polyester, and polyethylene) as raw materials, with a small amount of natural fibers (such as flax and cotton fibers, which are less commonly used nowadays) also included. They are processed and formed through non-woven processes (needle punching, thermal bonding, chemical bonding) or weaving processes (weaving). Some geotextile products undergo post-treatment like coating and lamination to enhance specific properties (e.g., anti-aging, waterproofing).

2. Physical properties:

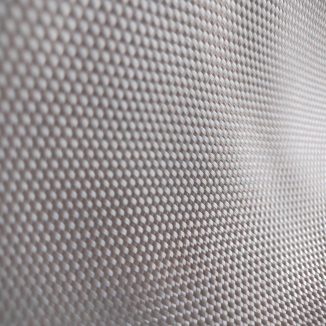

Permeability: Non woven geotextiles are mostly porous structures with good water permeability (typically ranging from 10 ⁻¹ to 10 ⁻ cm/s), allowing water and gas to pass through but blocking solid particles; The permeability of woven geotextile depends on the fiber gap and can be adjusted as needed.

Density and thickness: The density is usually 100-800 g/㎡ (conventional range), and the thickness increases with the increase of density, generally 1-5 mm. In special scenarios (such as buffering), it can reach more than 10 mm.

Environmental resistance: Synthetic fiber materials give them the characteristics of acid and alkali resistance (stable within the pH range of 3-11), salt spray resistance, and microbial erosion resistance, while natural fibers need to undergo anti-corrosion treatment before they can be used in outdoor scenes.

3. Mechanical properties:

Tensile strength: The transverse and longitudinal tensile strength is usually 5-50 kN/m, which can be improved by adjusting the fiber type (such as polyester fiber having higher strength than polypropylene) and process (such as woven fabric having better tensile strength than non-woven fabric) to meet different engineering load requirements.

Tear strength and burst strength: Tear strength (the ability to resist local tearing) is generally 0.5-5 kN, and burst strength (the ability to resist vertical pressure) is 1-10 kN, ensuring that it is not easily damaged during construction and use.

Core Function: The Core Role in Engineering

1. Filtration function: This is one of the most fundamental functions of geotextiles. When water flows through geotextiles, their porous structure can intercept solid impurities such as soil particles and sand, preventing soil erosion; At the same time, allow clear water to pass smoothly and avoid pore blockage (such as using alternative materials for "filter layers" in hydraulic engineering to replace traditional sand and gravel filter layers and reduce the amount of work).

2. Drainage function: With the help of its own pore channels or composite with other drainage materials (such as geotextile drainage network), excess water (such as rainwater and groundwater) in the rock and soil is diverted to designated locations (such as drainage blind ditches), reducing the soil moisture content and avoiding soil softening and strength reduction caused by water accumulation (such as roadbed frost heave, dam piping, etc.).

3. Separation function: By utilizing the barrier properties of geotextiles, two or more materials with different physical properties (such as soil and sand, sand and concrete, roadbed soil and ballast) are separated to prevent performance degradation caused by mixing of different materials. For example, in roadbed construction, geotextile can isolate the bottom layer of soft soil from the upper layer of filling material, avoiding the filling material from sinking into the soft soil while maintaining their respective structural integrity.

4. Reinforcement function: By utilizing the tensile strength of geotextiles, a "composite structure" is formed with the soil, which transfers and disperses the loads (such as vehicle loads and self weight of fill) received by the soil to a larger area of soil, enhancing the overall bearing capacity and deformation resistance of the soil (such as reducing roadbed settlement and enhancing slope stability).

Main features: Core differences from traditional materials

1. Lightweight and convenient: The weight of a single roll of geotextile is usually 50-200 kg, with a thin thickness (1-5 mm) and low transportation and storage costs; No large equipment is required during construction, manual laying is sufficient, and the efficiency is much higher than that of traditional sand and gravel filter layers (traditional sand and gravel layers require layered paving and compaction, and the process is complex), which can shorten the construction period by 30% to 50%.

2. Strong controllability of performance: By adjusting raw materials (such as polypropylene vs polyester), processes (needle density, weaving method), and post-treatment (coating, composite), the key indicators of geotextile such as tensile strength, permeability, and aging resistance can be accurately controlled to meet the personalized needs of different projects (such as high permeability required for water conservancy projects and high corrosion resistance required for landfills).

3. Excellent economy: Although the unit price of geotextile is higher than that of sand and gravel, the overall cost is lower - on the one hand, it reduces the amount of traditional materials (such as sand and gravel) used (such as 1 ㎡ geotextile can replace 3-5 ㎡ sand and gravel filter layer), and on the other hand, it reduces transportation, construction, and maintenance costs (such as reducing maintenance costs caused by structural failure in the later stage), with a full life cycle cost 20% to 40% lower than traditional solutions.

4. Durability and environmental protection: the anti-aging performance of synthetic fiber geotextile (after adding antioxidant and ultraviolet stabilizer) can meet the project life of more than 50 years (such as the design life of highway and water conservancy projects); Some products can use biodegradable materials (such as polylactic acid fibers), which are suitable for temporary projects (such as temporary roadbeds) to avoid long-term environmental impacts.

5. Wide adaptability: It can adapt to complex terrains (such as steep slopes and curved embankments), and can deform with the terrain during installation, with a high degree of fit; At the same time, it can tolerate extreme environments (temperature range of -40 ℃~80 ℃, acidic and alkaline soil), and can still play a stable role in special scenarios such as high cold, saline alkali land, and mining areas.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Water conservancy engineering: mainly used for preventing leakage and erosion. For example, laying geotextile between the dam body and foundation of earth rock dams or embankments to filter soil particles and prevent water seepage from causing damage to the dam body; Lay geotextile on the slope protection of rivers and reservoirs to resist water erosion and prevent bank slope collapse.

2.Transportation engineering: the core solution to the problem of roadbed stability. Laying geotextile on soft soil foundation of highways and railways can enhance the bearing capacity of the foundation and reduce settlement; Laying geotextile between the gravel layer of the roadbed and the soil foundation can prevent material mixing, accelerate rainwater drainage, and avoid roadbed softening.

3.Construction project: primarily used for anti-seepage and drainage. Laying geotextile on the side walls and bottom plates of the basement, combined with a drainage system, can guide away soil seepage and prevent leakage; Laying geotextile during roof greening or excavation slope construction can isolate different materials and protect the structure from friction damage.

4.Environmental engineering: The key role is isolation and filtration. Laying geotextile at the bottom of the landfill can isolate the leachate from the soil and avoid pollution; Laying geotextile in sedimentation tanks and artificial wetlands of sewage treatment plants can filter suspended particles in sewage and improve treatment efficiency.

In summary, geotextiles, with their flexible functions such as filtration, drainage, isolation, reinforcement, and protection, have targeted the core pain points of leakage, settlement, erosion, and pollution in engineering in the four major fields of water conservancy, transportation, construction, and environmental protection. They are low-cost and high-performance materials that enhance engineering stability, safety, and durability, and play an irreplaceable supporting role in the smooth construction and long-term operation of various projects.