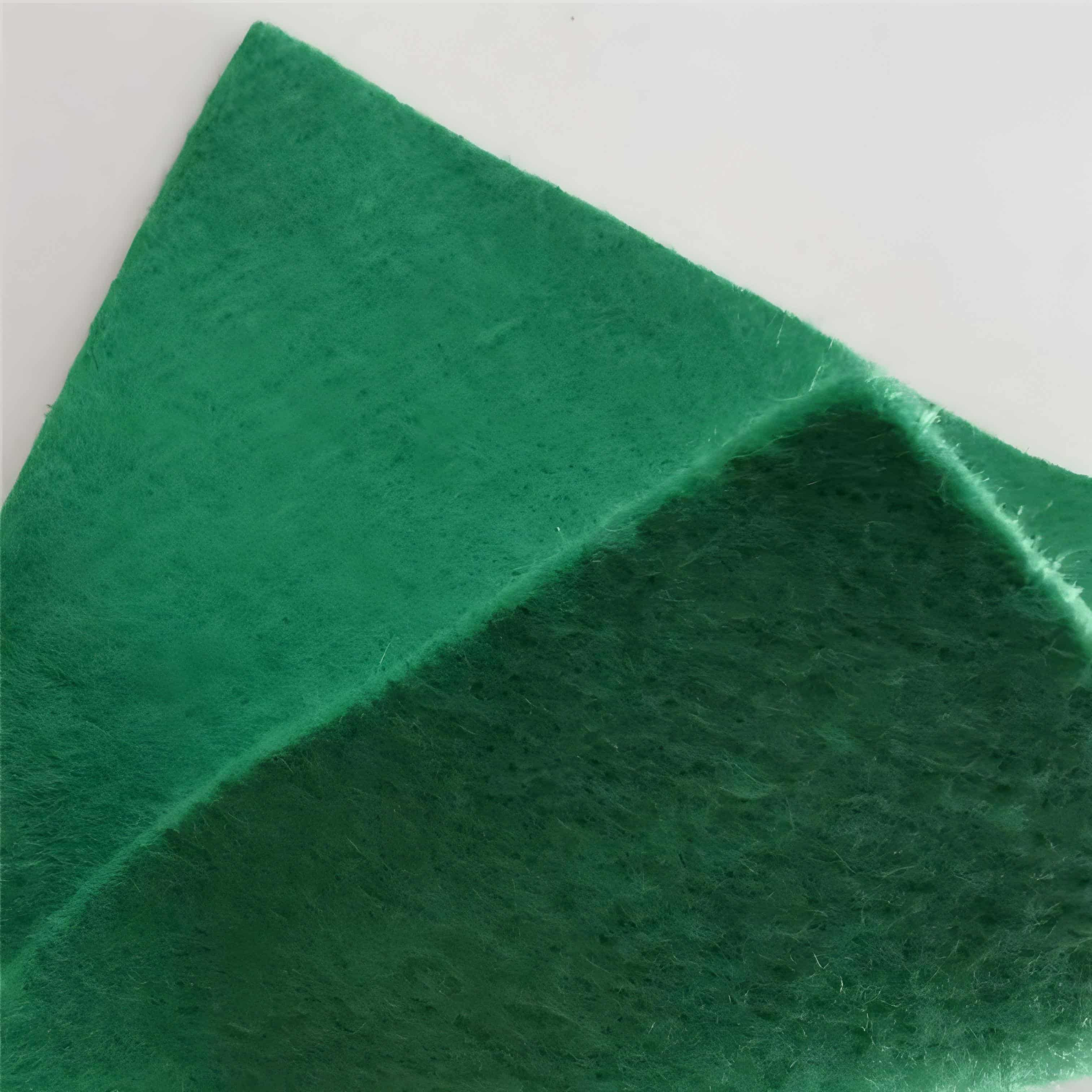

Geofabric Textile

1. Functional versatility: A single material can simultaneously achieve multiple functions, reducing the variety and cost of engineering materials.

2. Enhance engineering stability: By reinforcing the soil, the tensile and shear strength of the soil can be improved, and the service life of the project can be extended.

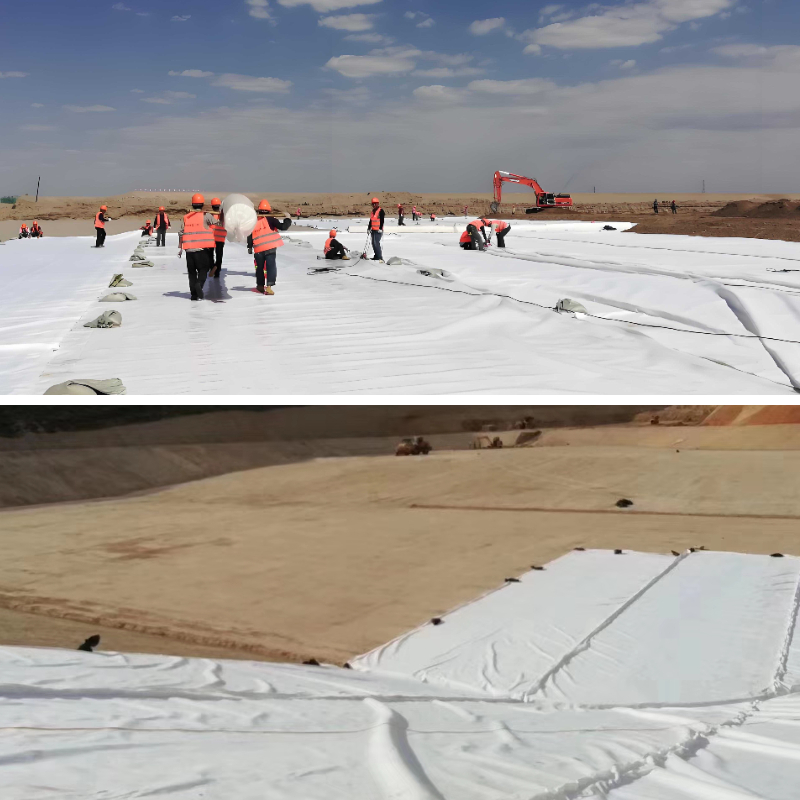

3. High construction efficiency: Easy to lay, can be operated mechanically, and has low requirements for the construction environment, shortening the construction period.

4. Good economy: Compared with traditional materials, geotextiles have lower costs and lower maintenance expenses in the later stage, with a high comprehensive cost-effectiveness.

Product Introduction:

Geofabric Textile is a permeable geosynthetic material made from synthetic fibers such as polyester and polypropylene through needle punching, weaving, or thermal bonding processes. The finished product is in the form of a cloth, with a width of generally 4-6 meters and a length of up to 50-100 meters. Its core function is to enhance soil stability through mechanisms such as physical isolation, filtration, drainage, and reinforcement, and it is widely used in fields such as civil engineering, water conservancy engineering, and environmental protection engineering.

Feature

1. High strength and durability

Plastic fiber material endows geotextiles with high strength and elongation in both dry and wet states, excellent tensile strength, burst strength, and puncture strength, and can withstand complex stresses during construction and use.

Resistant to chemical corrosion, UV radiation, and microbial damage, ensuring long-term service in acidic and alkaline soil and water.

2. Excellent permeability and filtration function

The gaps between fibers allow water flow to pass through while preventing soil particle loss and maintaining soil structure stability. For example, in dam engineering, geotextile can prevent the collapse of the dam body caused by water flow erosion.

3. Reliable isolation function

Placed between soil layers or materials with different physical properties (such as gravel and soft soil) to prevent mixing and maintain their respective design functions. For example, isolating sand and soil in highway roadbeds to prevent material mixing from causing collapse.

4. Auxiliary reinforcement and stress dispersion

After being buried in the soil, it provides additional tensile strength through friction, improves overall stability, disperses local loads, and reduces uneven settlement. For example, in slope reinforcement, geotextile can enhance soil tension and reduce landslide risk.

5. Dual function of protection and drainage

Buffer external impact damage to waterproof materials (such as protective geomembranes), or form flat drainage channels to collect and guide pore water or seepage water. For example, in tunnel engineering, geotextile can eliminate surrounding water seepage and reduce lining pressure.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Embankment and reservoir slope protection filter layer, river and coastal protection foundation, and canal anti-seepage protection. For example, geotextiles are used in the dam drainage system of the Three Gorges Project to ensure the safety of the dam.

2. Transportation infrastructure

Highway and railway subgrade isolation and reinforcement, soft foundation treatment, retaining walls and bridge abutment back drainage. For example, in the construction of the Hong Kong Zhuhai Macao Bridge, geotextiles were used to reinforce the foundation of underwater tunnels and enhance structural stability.

3. Environmental Protection Engineering

The protective layer of the landfill liner and the collection and drainage of leachate, as well as the anti-seepage of the sewage treatment tank. For example, the Beijing Asuwei landfill uses a geotextile composite structure to effectively isolate garbage from groundwater.

4. Municipal construction

Waterproof protection and drainage of underground structures (basements, tunnels), and protection of underground pipe networks. For example, in the construction of the Shanghai subway, geotextile is used for drainage around the tunnel to prevent water accumulation from causing structural damage.

5. Environmental restoration and landscape

Ecological slope protection, artificial wetland filter layer, and stable sports field foundation. For example, in the construction of venues for the Hangzhou Asian Games, geotextiles were used for lawn drainage to ensure the quality of the venue.

6. Innovative applications in family scenarios

Garden and vegetable fields are protected against weeds, temporary waterproofing during rainy season, protective measures for moving and storage, and moisture-proof measures for outdoor camping. For example, laying geotextiles in a home garden can suppress weed growth while maintaining soil permeability.

Geotextile, as a high-performance geosynthetic material, has become a "behind the scenes hero" in modern infrastructure construction due to its excellent multifunctionality, economy, and environmental friendliness. It solves complex engineering problems through simple principles, greatly improving the quality, efficiency, and sustainability of engineering.