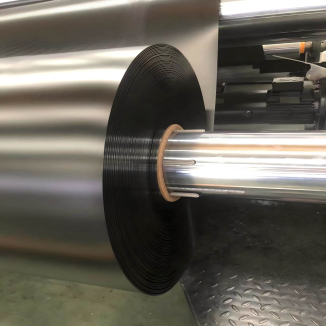

Filament Geotextile

1. Uniform and stable quality: Industrial production ensures consistent performance indicators, avoiding the problem of uneven quality of natural materials.

2. High construction efficiency: fast laying speed, requiring less equipment and manpower, greatly shortening the construction period.

3. Low comprehensive cost: Although the material itself has costs, it saves a lot of transportation, labor, and sand and gravel costs, and the overall economic benefits are significant.

4. Strong adaptability: The texture is soft and can adapt well to uneven foundation deformation.

Product Introduction:

Filament Geotextile refers to a sheet material made from high molecular weight polymers and processed to have permeability. It is mainly used for engineering functions such as isolation, filtration, drainage, reinforcement, and protection, and is an important component of geosynthetic materials. It is different from traditional fabrics and focuses more on engineering performance (such as strength, corrosion resistance, permeability, etc.).

Feature

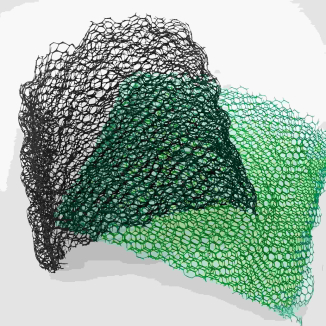

1. Diverse materials: The raw materials include synthetic fibers such as polyester (PET), polypropylene (PP), polyethylene (PE), etc. Some products will add natural fibers (such as cotton and linen) to enhance specific properties.

2. Flexible structure: According to different processes, it can be divided into needle punched non-woven geotextiles, woven geotextiles, woven geotextiles, composite geotextiles, etc. The structural differences directly affect their functions (such as good breathability of needle punched fabrics and high strength of woven fabrics).

3. Strong environmental resistance: acid and alkali resistant, corrosion-resistant, able to adapt to the chemical environment in soil; At the same time, it has certain anti ultraviolet and anti-aging capabilities, and extends the service life of the project.

4. Controllable permeability: By adjusting the fiber density and structure, different permeability rates can be achieved to meet the needs of filtration (preventing soil particle loss) or drainage (exporting moisture).

5. Flexibility and strength balance: The texture is soft and can adapt to terrain deformation; Simultaneously possessing high tensile strength and tear strength, capable of withstanding soil pressure and external impact.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering:

The anti-seepage and filter layer of dams and channels (to prevent soil from being washed away by water flow);

Slope protection in river regulation to reduce erosion of riverbanks by water flow.

2. Transportation Engineering:

Isolation layer for highway and railway subgrade (separating different soil layers to prevent mixing);

Roadbed drainage (draining accumulated water to avoid roadbed settlement);

Road reinforcement (enhancing roadbed stability and reducing road cracking).

3. Municipal engineering:

The anti-seepage and filtering layer of the landfill site (to prevent soil and groundwater contamination by leachate);

Drainage system for underground parking lots and tunnels (to remove accumulated water from structures).

4. Geotechnical Engineering:

Slope protection (reinforced soil slope, enhancing slope anti sliding stability);

Soft soil foundation treatment (sharing load and reducing settlement through reinforcement).

5. Agriculture and Environmental Protection:

Anti seepage and filtration of irrigation channels in farmland;

The lining material of artificial wetlands purifies water quality.

Geotextile, with its unique properties and advantages, has become an indispensable material in modern engineering construction, playing a key role in improving engineering quality, reducing costs, and protecting the ecological environment. With the development of technology, its functions are constantly expanding.