Geotextile 100 m

1. Improve engineering quality: By isolating materials of different properties to prevent them from mixing with each other, the stability of the engineering structure is ensured

2. Reduce engineering costs: Compared with traditional engineering materials, geotextiles have relatively lower prices and are easy to construct, reducing the overall cost of the project.

3. Enhance engineering safety: In slope protection, dam reinforcement and other engineering projects, geotextiles can disperse the stress of soil, prevent soil sliding and collapse, and improve the disaster resistance and safety of the project.

Product Introduction:

Geotextile for Pavers is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. Its finished products are in the form of cloth, with a width of usually 4-6 meters and a length of up to 50-100 meters. They are divided into two categories: woven geotextiles (such as woven fabrics) and non-woven geotextiles (such as short fiber needle punched fabrics and long fiber spunbond fabrics).

Core Features

1. High strength and durability

High tensile strength, capable of withstanding complex stresses during construction and use, such as dispersing loads in steep slope reinforcement to prevent landslides.

Resistant to chemical corrosion, UV radiation, and microbial damage, ensuring that performance can be maintained even in acidic or alkaline environments or long-term exposure. For example, polyester (PET) geotextile is resistant to high temperatures and creep, and is suitable for high and steep slopes; Polypropylene (PP) geotextile is acid and alkali resistant and is commonly used for landfill protection.

2. Excellent permeability and filtration function

There are gaps between the fibers, allowing water flow to pass through while intercepting soil particles, fine sand, etc., to prevent soil erosion. For example, in riverbank slope protection, geotextile can filter out sediment in the water flow and avoid clogging of the drainage system.

3. Reliable isolation function

Placed between different soil layers or materials (such as gravel and soft soil) to prevent mixing and maintain their respective functions. For example, when building roads on soft soil foundations, geotextiles can separate soil and gravel, improving the stability of the roadbed.

4. Auxiliary reinforcement and stress dispersion

After being buried in the soil, additional tensile strength is provided through friction to enhance overall stability. For example, in the backfilling of retaining walls, geotextiles can reinforce the soil and prevent reflection cracks.

5. Dual function of protection and drainage

Buffer external impacts (such as protecting geomembranes from being pierced by sharp objects), or form drainage channels to drain pore water. For example, in tunnel engineering, geotextile can eliminate surrounding water seepage and reduce lining pressure.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

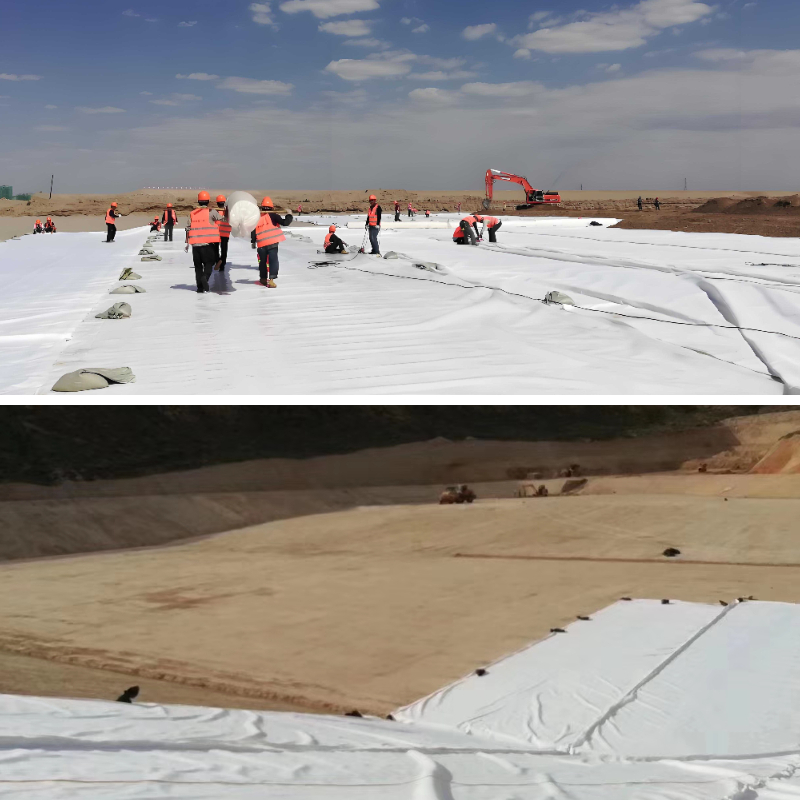

Product Applications:

1. Water conservancy engineering

Embankment and reservoir slope protection filter layer, river and coastal protection foundation, and canal anti-seepage protection. For example, geotextiles are extensively used in the Three Gorges Project to reinforce the dam body and prevent leakage.

2. Transportation infrastructure

Highway and railway subgrade isolation and reinforcement, soft foundation treatment, retaining walls and bridge abutment back drainage. For example, in the construction of the Qinghai Tibet Railway, geotextiles were used for roadbed reinforcement in permafrost areas to prevent frost damage.

3. Environmental Protection Engineering

The protective layer of the landfill liner and the collection and drainage of leachate, as well as the anti-seepage of the sewage treatment tank. For example, the Beijing Asuwei landfill uses geotextile/geomembrane composite materials to effectively prevent harmful substances from infiltrating the soil.

4. Municipal construction

Waterproof protection and drainage of underground structures (basements, tunnels), and protection of underground pipe networks. For example, in the underground works of Shanghai center Building, geotextile is used for drainage system to avoid ponding.

5. Environmental restoration and landscape

Ecological slope protection, artificial wetland filter layer, and stable sports field foundation. For example, in the Xixi Wetland Project in Hangzhou, geotextile is used for wetland slope protection to promote vegetation growth.

6. Family scene

Garden and vegetable field grass prevention, emergency cover for roof leakage, and protection for moving and storage. For example, laying geotextiles in a home garden can suppress weed growth and reduce the workload of weeding.

Geotextile, as an efficient, economical, and environmentally friendly engineering material, plays an indispensable role in modern civil engineering due to its excellent mechanical and hydraulic properties. It not only solves many traditional engineering technical problems, but also promotes the development of engineering construction towards a more efficient and sustainable direction.