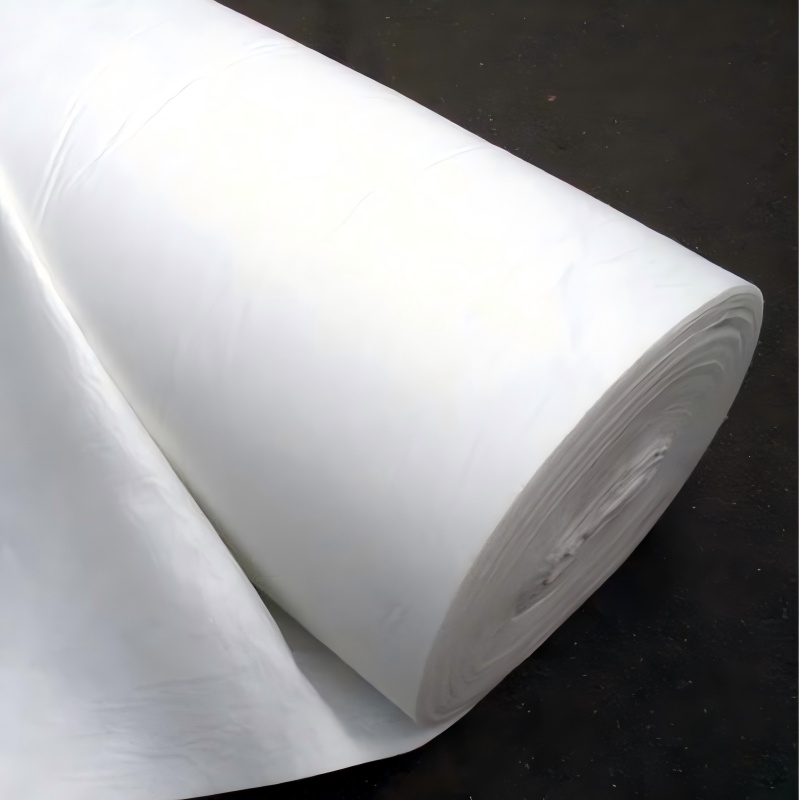

Geotextile 10m

1.High construction efficiency: A width of 10m reduces the number of splices, shortens the laying time, and lowers the cost of joint treatment.

2.Wide coverage and adaptability: Adapt to most engineering standard width requirements, reduce material cutting waste, and improve site coverage integrity.

3.Cost optimization: Large unit area, lower transportation and labor costs per square meter, outstanding comprehensive cost-effectiveness.

4.Stronger integrity: Reducing the number of joints to lower the risk of leakage and fracture, ensuring the continuity of engineering protection effectiveness.

Product Introduction

1、 Basic attributes

Geotextile 10m refers to a geosynthetic material with a width of 10 meters, usually made of polymer fibers through non-woven or weaving processes, and has stable physical and mechanical properties. Its material is lightweight and flexible, with a large single width area that can be cut to length according to engineering needs, making it easy to transport, lay, and perform on-site construction operations, and suitable for the basic protection needs of various engineering scenarios.

2、 Core functions

As a commonly used material in engineering, its core functions are reflected in three aspects: firstly, efficient coverage and protection. With a width of 10 meters, it can quickly cover the construction area, form a continuous protective layer, and play a basic role in anti-seepage, water filtration, reinforcement, etc; The second is to simplify the construction process, reduce the complexity of construction by reducing splicing operations, and ensure the continuity of project laying; The third is to adapt to engineering requirements, meet the standard width requirements of most projects, and provide stable structural support and protection for scenarios such as roads, water conservancy, and slopes.

3、 Main features

Convenient and efficient construction: With a width of 10 meters, the number of splices is greatly reduced, the laying time is shortened, the labor and material costs of joint treatment are reduced, and the construction efficiency is improved.

Strong coverage adaptability: Meets the standard width requirements of most projects, reduces cutting waste caused by inconsistent width, and improves the integrity and tightness of site coverage.

Significant cost advantages: large single width area, lower transportation and laying labor costs per square meter, and better overall cost-effectiveness than narrow width geotextiles.

Good overall protection: reducing the number of joints reduces the risks of leakage, breakage, etc., ensuring the continuity and stability of the engineering protection effect, and enhancing the overall protection capability.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Road engineering: improving the efficiency of grassroots paving

In the construction of rural and municipal road base, 10 meter wide geotextile can be continuously laid along the longitudinal direction of the road, reducing the number of horizontal joints of the roadbed. It can quickly cover the surface of the roadbed, evenly disperse vehicle loads, and discharge accumulated water from the base layer through permeability to avoid roadbed softening. The large width design adapts to the standard width requirements of roads, reduces the cost of joint treatment, and improves the overall stability of roadbed reinforcement.

2. Water conservancy engineering: Strengthen anti-seepage and drainage continuity

In scenarios such as small reservoir embankments and agricultural irrigation channels, a 10 meter wide geotextile can be fully laid along the embankment slope or channel bottom to form a continuous impermeable layer. The tight width coverage reduces the risk of joint leakage, which can not only block water leakage to the outside of the dam, but also filter sediment in the water to prevent blockage of drainage channels, ensuring the water transmission efficiency and anti-seepage effect of water conservancy facilities.

3. Slope protection: enhance the integrity of soil and water conservation

For the protection of large-scale mountain slopes and embankment slopes, a 10 meter wide geotextile is laid through horizontal overlapping and vertical anchoring, which can quickly cover the surface of the slope. Its fiber structure fixes the surface soil, reduces soil erosion caused by rainwater erosion, and allows for the infiltration and discharge of moisture inside the slope. The large width design reduces the splicing gap of slope protection, enhances the continuity of overall protection, and reduces the risk of landslides.

4. Municipal infrastructure: optimizing site coverage and isolation effect

In municipal projects such as underground parking lot foundations and large-scale site leveling, 10 meter wide geotextile can be used as a soil isolation layer or anti-seepage protection layer. A single large coverage area reduces mixed pollution of different soil layers, while providing continuous protection for underground pipelines, impermeable membranes, etc., to avoid damage caused by sharp objects. There is no need for frequent splicing during construction, which improves the efficiency of site foundation treatment and overall protection quality.

Geotextile 10m, with its core advantage of a width of 10 meters, has demonstrated efficient and practical value in engineering fields such as roads, water conservancy, slopes, and municipal engineering. It improves construction efficiency by reducing the number of splicing times, reduces joint risks to ensure continuous protection, and adapts to various engineering width requirements to reduce material waste. Whether it is strengthening structural stability, enhancing anti-seepage and drainage effects, or improving soil and water conservation capacity, it provides strong support for the safe construction, efficient promotion, and long-term stable operation of engineering. It is a high-quality geotechnical material that combines economy and practicality.