Best Geotextile

1. Comprehensive performance coverage: integrating reinforcement, isolation, drainage, and protection functions, suitable for multiple scenarios such as roadbeds, slopes, and brick laying, meeting the core requirements of different projects.

2. Excellent durability performance: Selected high-strength materials, tear resistant and wear-resistant, treated with UV and corrosion resistance, stable performance in harsh environments, and long service life.

3. Efficient construction adaptation: The texture is flexible and easy to cut, which can quickly fit complex terrain. No professional equipment is required for laying, greatly shortening the construction period and reducing construction costs.

4. Win win ecological economy: Help stabilize engineering structures and reduce post maintenance; Some models are compatible with vegetation growth, balancing protection and ecological restoration, with outstanding comprehensive benefits.

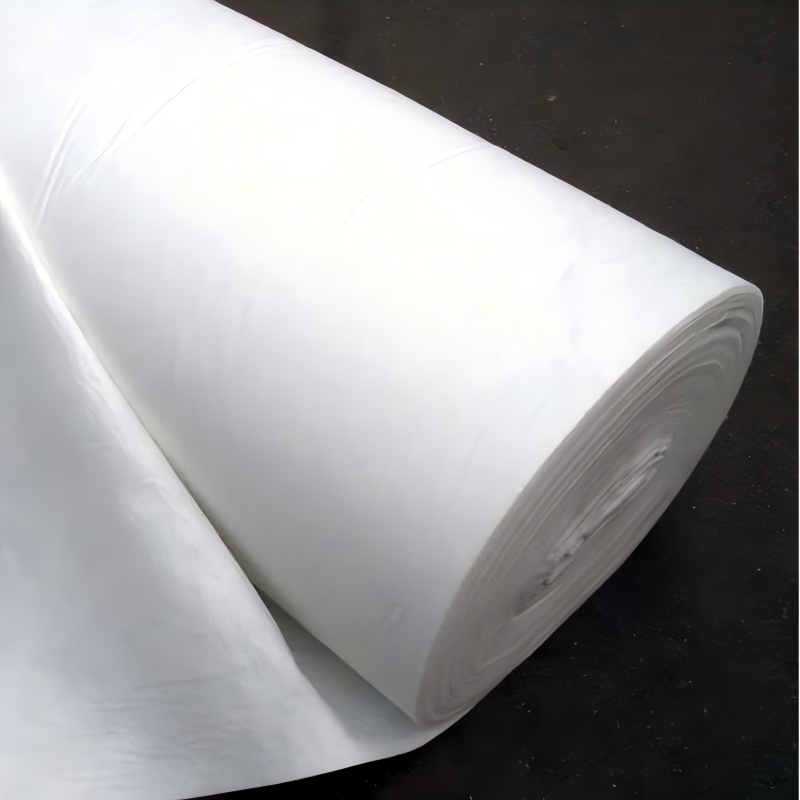

Products Introduction:

Best Geotextile is a type of geosynthetic material with excellent comprehensive performance. It is made from high-strength polymer materials such as polypropylene and polyester, and processed through advanced processes such as weaving, needle punching, and composite. It combines multiple functions such as reinforcement, isolation, filtration, drainage, and protection, and can provide targeted solutions according to different engineering needs. As a key material in modern engineering construction, its core value lies in improving the stability of engineering structures, extending their service life, and reducing overall costs through excellent physical properties and environmental adaptability. It is widely used in various fields such as transportation, water conservancy, construction, and environmental protection, and is an ideal choice to ensure engineering quality and efficiency.

Product Features:

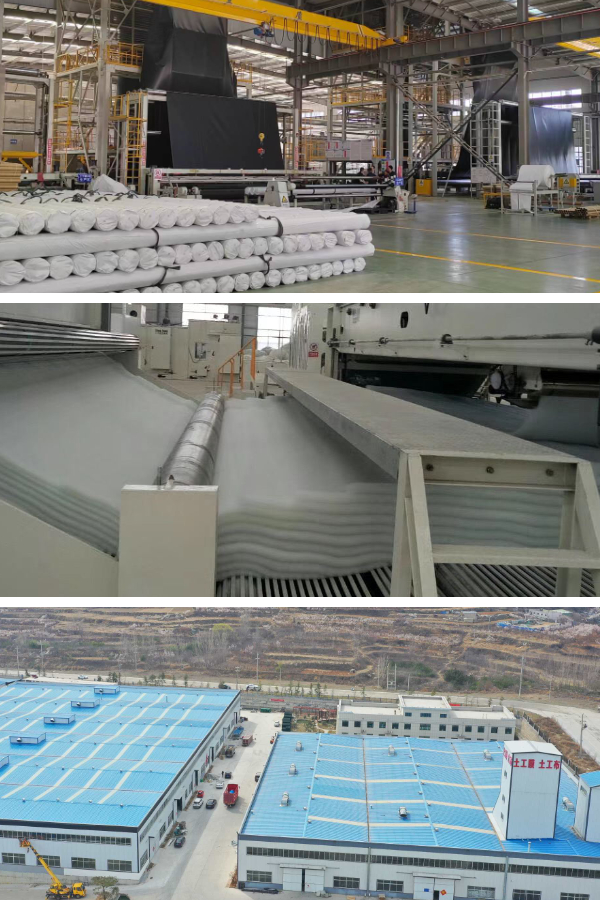

1. Comprehensive performance integration: Breaking through the limitations of a single function and achieving "one material for multiple uses". Woven fabric has ultra-high tensile strength (up to 300kN/m), suitable for heavy-duty engineering reinforcement; The non-woven fabric has a porosity of 70% -90% and excellent filtration and drainage efficiency; The composite design combines the advantages of both, while meeting the needs of reinforcement and infiltration, and can adapt to diverse scenarios ranging from lightweight sites to complex engineering.

2. Extremely durable performance: select the materials with the highest weather resistance, and undergo triple treatment of ultraviolet resistance, acid and alkali resistance, and aging resistance. Stable performance at extreme temperatures ranging from -40 ℃ to 80 ℃, resistant to soil corrosion and mechanical wear. Even if exposed to harsh environments such as outdoor wind and rain, saline alkali land, etc. for a long time, the service life can still reach 20-30 years, greatly reducing the frequency of material replacement.

3. Precise scene adaptation: Provides multiple specifications from 100g/m ² to 1000g/m ², with thickness and strength customizable according to needs. For special scenarios such as soft soil foundation, steep slopes, and saline alkali areas, it is possible to accurately match engineering loads, hydrological and geological conditions by adjusting parameters such as fiber density and pore size, ensuring maximum functionality.

4. Efficient construction guarantee: The material is lightweight and flexible, with a width of up to 6-8 meters, reducing the number of splicing times. It can be quickly cut with ordinary tools, and can be laid manually or mechanically. It fits irregular terrain (such as curved surfaces and steep slopes) without wrinkles, and the construction efficiency is increased by more than 30% compared to traditional materials, significantly shortening the construction period and reducing labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Core protection of transportation engineering: used as a reinforcement layer in highway and railway subgrades to disperse vehicle loads and reduce settlement; Serve as a buffer layer between the tunnel lining and the surrounding rock, absorbing the pressure of the surrounding rock; Replace traditional sand and gravel cushion layers in rural road renovation, enhance road resistance to rolling, and meet the needs of agricultural vehicle traffic.

2. Water conservancy and ecological restoration: used for anti-seepage reinforcement of rivers and reservoir embankments, composite anti-seepage membranes can reduce leakage by more than 90%; In mining reclamation and slope greening, as a carrier of vegetation growth, combined with spraying technology, the dual effect of "material reinforcement+ecological restoration" is achieved to reduce the risk of soil erosion.

3. Building and municipal foundation: Separate different soil layers in building foundation treatment to prevent material mixing; As a drainage filter layer in the construction of underground pipe galleries and parking lots, it can quickly drain accumulated water; In rooftop gardens and sponge city projects, guide rainwater infiltration and block soil particles to protect building structures.

4. Special engineering solution: In the anti-seepage system of the landfill site, it serves as a protective layer to prevent the anti-seepage membrane from being punctured by sharp objects; In the improvement project of saline alkali land, the upward movement of salt is blocked by an isolation layer; Quickly build temporary roads in large event venues and construction sites to withstand the passage of heavy machinery.

Best Geotextile, with its versatile performance integration, ultimate durability, precise scene adaptation, and efficient construction support, has become a "multifunctional protection expert" spanning multiple fields of engineering. It not only fundamentally solves the performance shortcomings of traditional materials in reinforcement, drainage, isolation, etc., but also meets the special needs of complex engineering through customized solutions, greatly improving the stability and durability of the project. Whether it is a large-scale infrastructure project or a small-scale livelihood project, its characteristic of "one-time investment and long-term benefits" can significantly reduce the full life cycle cost. It is the core material for promoting the efficient, green, and sustainable development of engineering construction, and also the preferred solution for improving quality and efficiency in the field of modern engineering.