Best Geotextile Tubes for Wastewater Treatment

1. Easy to operate: No complex installation process is required, it can be quickly put into use, reducing the difficulty of manual operation.

2. Strong durability: Made of high-strength materials, it is resistant to tensile and tear, and has a service life far exceeding traditional equipment.

3. Thoroughly processed: capable of deeply intercepting sludge particles, improving effluent clarity, and meeting strict discharge standards.

4. Good compatibility: It can seamlessly integrate with existing sewage treatment systems without the need for large-scale facility renovation.

5. Widely applicable: Whether it is industrial wastewater or municipal sewage, it can efficiently adapt to the treatment needs.

Products Introduction:

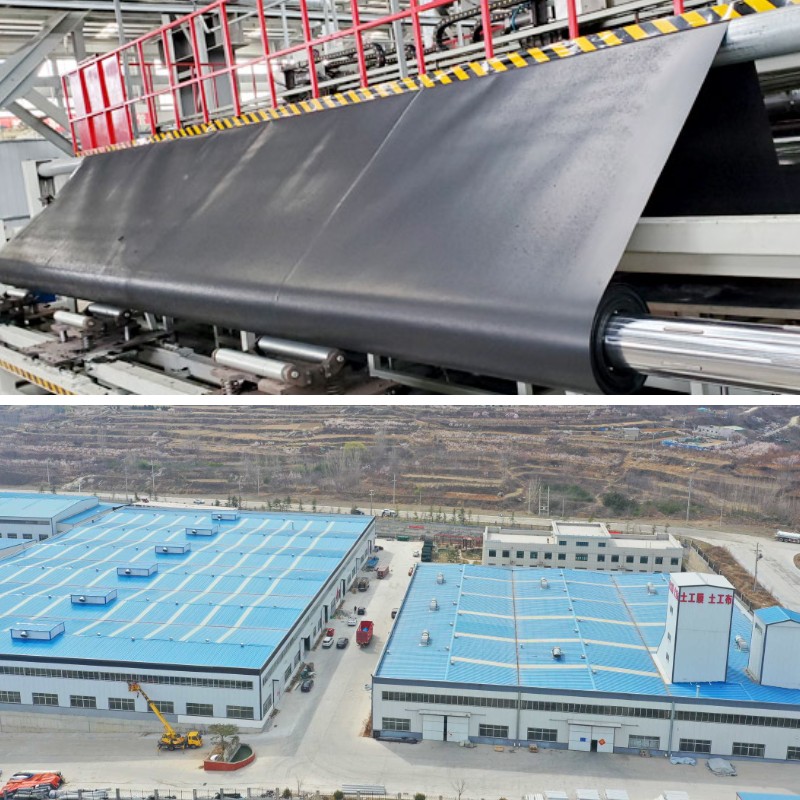

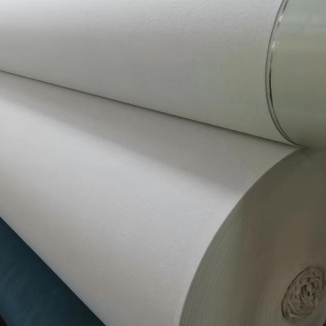

Best Geotextile Tubes is an efficient product designed specifically for wastewater treatment, made of high-strength geotextiles with excellent filtration and dewatering performance. The fabric created through special weaving techniques not only ensures structural strength, but also precisely controls pore size, effectively separating solid and liquid components in wastewater. This product is tubular and can be customized in size according to different project requirements. The common length ranges from 22 feet to 200 feet, and the circumference ranges from 22.5 feet to 120 feet. It also has filling ports with a spacing of approximately every 50 feet, making it convenient to evenly fill sewage and distribute internal materials.

Product Features:

1. High strength filtering material: It is woven from high-quality and high toughness polypropylene yarn and other materials. The fabric has high tensile strength and can withstand the impact and friction of solid particles in sewage. It is not easily damaged and ensures long-term stable operation. At the same time, its fine weaving structure makes the pores uniform and small, which can effectively intercept impurities such as sludge, sediment, suspended solids, etc. The filtration accuracy is high, ensuring that the discharged water quality is clear and meets the standard.

2. Excellent weather resistance and corrosion resistance: It has strong UV resistance and can be used outdoors for a long time without aging or deterioration; It has good tolerance to chemicals such as acid and alkali, and can adapt to complex and diverse water quality environments such as industrial wastewater and municipal sewage. Whether it is highly acidic chemical wastewater or alkaline papermaking wastewater, it can stably function and greatly extend the service life of the product.

3. Flexible size customization: Suitable size specifications can be customized according to the actual space limitations, sewage volume, and treatment needs of the project. From small-scale sewage treatment plants to large-scale municipal sewage treatment plants, suitable products can be found for projects of different scales to meet diverse engineering scenarios and maximize space utilization and treatment efficiency.

4. Convenient installation and maintenance: Prefabricated production, easy on-site installation, no need for complex construction equipment and processes. Daily maintenance only requires regular inspection of the appearance for damage, cleaning of debris that may block the filling port, etc. The maintenance cost is low, greatly reducing the operational burden of the project.

5. Efficient dehydration performance: The unique fabric structure allows moisture to pass through quickly while preventing the loss of solid particles, achieving efficient dehydration. When dealing with sludge and silt with high moisture content, it can quickly reduce their moisture content, improve subsequent treatment efficiency, reduce sludge volume, and lower transportation and disposal costs.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Municipal sewage treatment: In urban sewage treatment plants, it can be used for dewatering the remaining sludge discharged from primary and secondary sedimentation tanks, reducing the sludge moisture content to a suitable level for subsequent landfill, incineration, or resource utilization; It can also handle sediment and debris in rainwater collection systems, purify rainwater, and reduce the burden on subsequent pipelines and treatment facilities.

2. Industrial wastewater treatment: Suitable for various industrial enterprises such as chemical, pharmaceutical, printing and dyeing, steel, etc. For example, chemical companies can utilize the wastewater generated during their production process, which contains a large amount of chemicals and suspended particles; Steel plants are used to treat sludge generated by desulfurization and dust removal, effectively separating water and solid impurities, achieving the recycling of water resources and the rational disposal of solid waste.

3. In the agricultural field, it can be used for the treatment of manure and sewage from agricultural, animal husbandry, and fishery farms, filtering organic matter and solid residues, purifying water quality, and preventing direct discharge of sewage from polluting the surrounding water environment; It can also treat plantation wastewater, remove sediment, fertilizer residues, etc., and protect soil and water resources.

4. Water conservancy engineering and river management: In dredging projects for rivers and lakes, it is used for dewatering and treating the dredged silt. After separating the moisture in the silt, the remaining dried silt can be used for landfilling, land reclamation, etc; It can also be set in areas prone to water erosion such as riverbanks and coasts, filled with materials such as sand and gravel, to protect the bank, prevent waves, and resist erosion, ensuring the stability of the embankment and reducing soil erosion.

Best Geotextile Tubes has demonstrated significant advantages in the field of wastewater treatment with its unique product design and outstanding performance. From the perspective of product characteristics, high strength, weather and corrosion resistance, customizable size, and convenient maintenance make it suitable for complex and diverse application scenarios; In practical applications, it widely covers multiple fields such as municipal, industrial, agricultural, and water conservancy, providing efficient solutions for sewage treatment problems in different industries. Through efficient filtration and dehydration functions, this product can not only improve sewage treatment efficiency and reduce environmental pollution risks, but also save a lot of treatment costs for enterprises and society, achieving a win-win situation of economic and environmental benefits. Whether dealing with increasingly strict environmental standards or meeting the future development needs of the sewage treatment industry, Best Geotextile Tubes will be a reliable and high-quality choice.