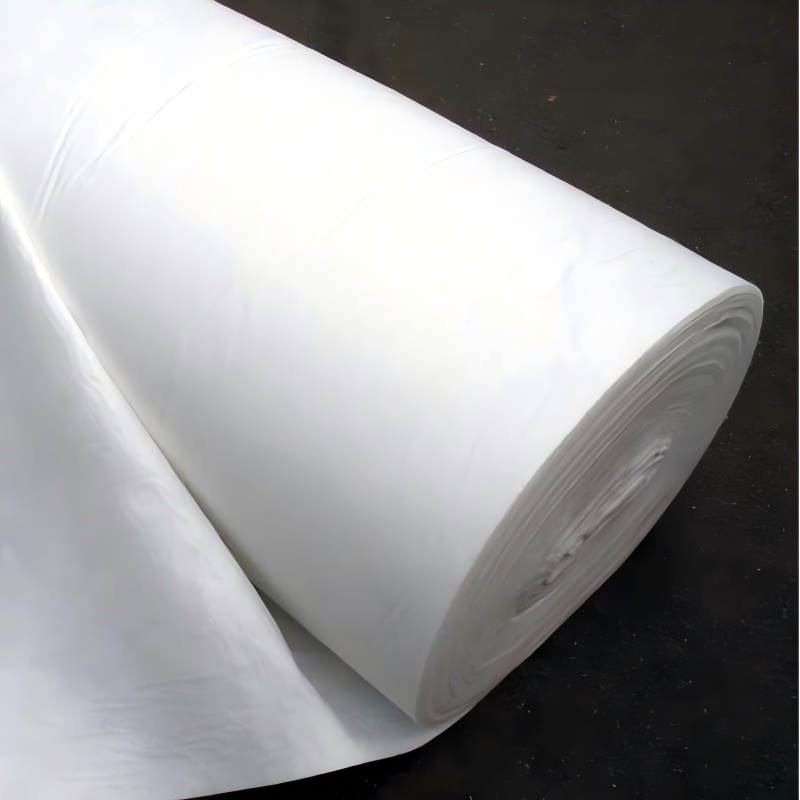

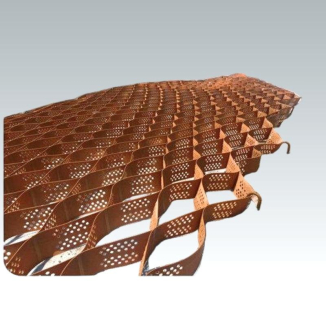

PP Woven Geotextile

1.Excellent mechanical properties: High tensile strength, tear strength, etc., which can stabilize engineering structures.

2.Strong corrosion resistance: Resistant to acids, alkalis, salts, etc., adaptable to complex environments with a long service life. Good water permeability and filtration: Pores can drain water while intercepting soil particles, preventing loss and settlement.

3.Superior weather resistance: Resistant to ultraviolet rays, high and low temperatures, with slow performance attenuation when used outdoors.

4. Low construction cost: Lightweight and easy to lay, with high efficiency and lower material cost compared to traditional ones.

5.Relatively good environmental protection: Little pollution in production, some can be recycled, meeting environmental protection requirements.

Product Introduction

1.Basic attributes

PP Woven Geotextile is a permeable geosynthetic material made primarily from polypropylene through spinning, weaving, or non-woven processes. Its chemical properties are stable, and its molecular structure does not contain polar groups, therefore it has the characteristics of acid alkali and salt corrosion resistance; Physically, the texture is lightweight, with a density lower than water and good flexibility, and can be cut into different sizes according to engineering requirements. Meanwhile, as a polymer material product, its production process relies on processes such as melting and molding of polypropylene resin. The finished product has a certain mechanical strength and porosity, making it a commonly used functional material in civil engineering.

2.Core functions

Reinforcement and strengthening: With high tensile strength and deformation resistance, embedded in soil or structural layers, it can disperse loads, constrain soil displacement, improve the stability of foundations or slopes, and reduce engineering damage caused by settlement and landslides.

Filtering and anti filtering: By using its own uniform pore structure, it achieves the effect of "water passing through soil but not exceeding soil" in water conservancy, road and other engineering projects - allowing water to penetrate smoothly while intercepting soil particles, preventing soil erosion or structural failure caused by the loss of fine particles.

Drainage and water diversion: By utilizing the channels between fibers, excess water in the soil is discharged, reducing pore water pressure, avoiding soil softening due to accumulated water, and ensuring the dryness and stability of the engineering structure.

Isolation and protection: It can separate materials such as sand, gravel, and soil with different particle sizes to prevent mixed pollution, while reducing the erosion of the external environment (such as chemicals and ultraviolet radiation) on the main body of the project and extending its service life.

3.Main features

Strong performance adaptability: Balancing permeability and mechanical strength, it can adjust parameters such as thickness and porosity according to engineering scenarios (such as highways, water conservancy, environmental protection) to meet different functional requirements.

Excellent environmental tolerance: Acid and alkali resistance, aging resistance, can be used for a long time in saline alkali land, humid or outdoor environments, strong ability to resist ultraviolet radiation and high and low temperature changes, slow performance degradation rate.

Outstanding construction and economy: Lightweight texture, convenient transportation and laying, can greatly improve construction efficiency; The raw material (polypropylene) has a wide range of sources, mature production processes, and lower costs than traditional materials such as sand, gravel, and concrete, which can reduce the total project cost.

Good environmental compatibility: Minimal pollution during the production process, some products can be recycled and reused, and will not cause secondary pollution to soil and water bodies, meeting the environmental requirements of modern engineering.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

Water conservancy engineering

Polypropylene geotextile plays a crucial role in hydraulic engineering. In terms of dam construction, it can be laid between the dam body and the foundation, playing a role in isolation and filtration, preventing the mixing of dam fill and foundation soil, and preventing water flow from carrying away fine particles in the dam body, ensuring the stability of the dam; In channel anti-seepage engineering, it can be used in conjunction with anti-seepage membrane to enhance the anti-seepage performance of the channel, reduce water resource leakage, and also discharge the accumulated water around the channel through drainage function to avoid soil softening affecting the channel structure.

Transportation Engineering

Transportation engineering is an important application scenario for polypropylene geotextiles. In highway construction, it is laid between the roadbed and the base layer. On the one hand, it can isolate sand and gravel materials of different particle sizes to prevent mixing of roadbed soil and base layer materials. On the other hand, it can disperse vehicle loads, reduce roadbed settlement, and extend the service life of the highway; For railway engineering, polypropylene geotextile can be used for foundation treatment under railway tracks, which enhances the bearing capacity of the foundation through reinforcement and also serves as drainage to avoid track deformation caused by accumulated water in the foundation.

Environmental Protection Engineering

Polypropylene geotextile is widely used in environmental engineering. In the construction of landfill sites, as a part of the anti-seepage system, it can effectively isolate garbage from surrounding soil and groundwater, prevent garbage leachate from polluting the environment, and its filtration performance can perform preliminary filtration on leachate; In river management projects, it can be used to reinforce riverbanks, prevent soil erosion, and provide a certain habitat for aquatic organisms, helping with ecological restoration.

Agricultural Engineering

Polypropylene geotextiles also perform well in agricultural engineering. In terms of agricultural irrigation, it can be used for laying irrigation channels, reducing water leakage, improving water resource utilization, and preventing channels from being blocked by soil particles; In the construction of agricultural greenhouses, laying them on the soil surface can provide moisture retention and prevent weed growth, which is beneficial for crop growth.

Mining Engineering

In mining engineering, polypropylene geotextile is mainly used for the treatment of slag yards. It can isolate slag from surrounding soil, prevent harmful substances in slag from penetrating into soil and groundwater, and play a role in environmental protection. At the same time, its reinforcement performance can enhance the stability of the yard and avoid safety accidents caused by slag collapse.

Polypropylene geotextile, with its diverse properties, has irreplaceable and important applications in many engineering fields such as water conservancy, transportation, environmental protection, agriculture, and mining. In hydraulic engineering, it safeguards the safety of dams and channels, ensuring the rational utilization of water resources; In transportation engineering, it safeguards the stability of highways and railways, extending the service life of transportation facilities; In environmental engineering, it plays a crucial role in protecting and restoring the environment in areas such as landfill and river management, helping to improve the ecological environment; In agricultural engineering, it provides strong support for agricultural production by improving irrigation efficiency and optimizing crop growth environment; In mining engineering, it balances environmental protection and safety in slag treatment, reducing the impact of mining production on the surrounding environment. It can be said that polypropylene geotextile, by fully utilizing its core functions of isolation, filtration, reinforcement, and drainage, not only provides solid guarantees for the safe, stable, and efficient operation of various projects, but also demonstrates significant value in promoting sustainable development of engineering construction, improving resource utilization efficiency, and protecting the ecological environment. It has become an indispensable and important material in modern engineering construction.