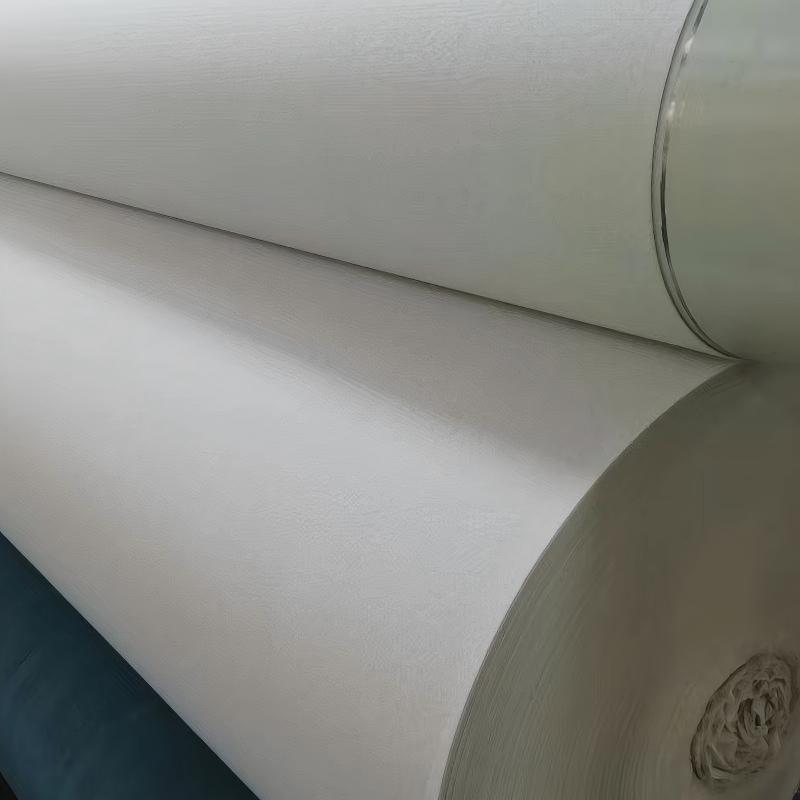

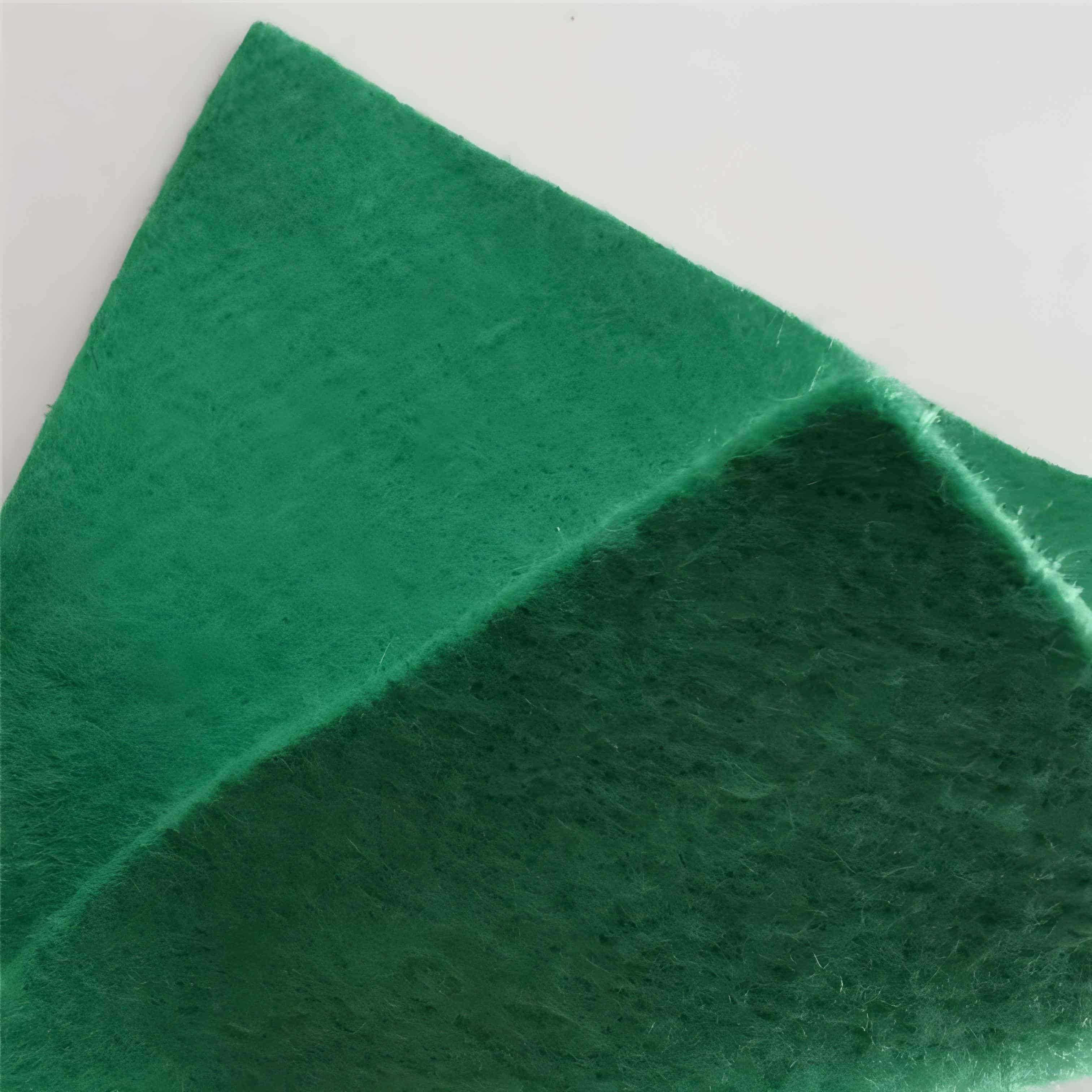

Polyethylene Geotextile

1.Strong Corrosion Resistance: Resistant to acid, alkali, salt corrosion and microbial attack, it does not age easily in complex environments such as soil and sewage, with a service life of 10-20 years;

2.Excellent Mechanical Properties: It has high tensile strength (≥10kN/m) and good tear resistance, capable of withstanding external forces like soil settlement and construction rolling, preventing damage;

3.Good Water Permeability and Filtration: It has uniform fiber pores (pore size: 0.05-0.5mm), which can quickly drain accumulated water in the soil while blocking the loss of sediment, protecting roadbeds/slopes;

4.Low Construction Cost: Lightweight (about 100-300g/㎡), easy to cut and splice, no complex equipment required, high transportation and laying efficiency, and the comprehensive cost is about 30% lower than that of traditional anti-seepage materials.

Product Introduction

1、 Basic attributes

Material: Polyethylene Geotextile is made from polyethylene (polymer synthetic material) as the raw material, with strong chemical stability;

Physical parameters: Conventional weight 100-300g/㎡, fiber pore size 0.05-0.5mm, tensile strength ≥ 10kN/m;

Service life: It is not easily aged in soil, sewage and other environments, and can be used normally for 10-20 years.

2、 Core functions

Permeable filtration: Quickly discharge soil water through uniform pores, while blocking sediment loss and maintaining soil structure;

Structural protection: With high resistance to tearing and rolling, it can withstand soil settlement and external construction forces, and protect engineering structures such as roadbeds and slopes;

Environmental adaptation: Resistant to acid, alkali, salt and microbial erosion, suitable for various complex engineering environments (such as municipal, water conservancy, road construction).

3、 Main features

Corrosion resistant and durable: Compared to traditional geotechnical materials, it has stronger resistance to chemical corrosion and biological damage, reducing later maintenance;

Convenient construction: lightweight material, easy to cut and assemble, no need for complex construction equipment, can improve laying efficiency;

Cost advantage: Comprehensive procurement, transportation, and construction costs are about 30% lower than traditional anti-seepage materials, with outstanding cost-effectiveness.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Water Conservancy Projects: Used for filtration and drainage in dikes, rivers, and reservoirs—for instance, intercepting sediment in water flow to prevent seepage-induced deformation of dikes. They also serve as protective layers for slope protection, reducing soil erosion on slope surfaces caused by water scouring.

2.Highway/Railway Projects: Laid between the subgrade and gravel base course, they play an isolating role to prevent the mixing of soil particles and gravel (which would reduce subgrade strength). Meanwhile, they assist in drainage to avoid subgrade settlement caused by water accumulation.

3.Environmental Protection Projects: In landfill sites, they act as filtering materials for leachate drainage layers, preventing garbage impurities from clogging the drainage system. They are also used as filter layers in constructed wetlands and sewage treatment plants to improve water purification efficiency.

4.Construction and Municipal Engineering: Used as drainage layers in underground garages and rooftop greening to quickly drain accumulated water. They also aid in soft soil foundation treatment by helping distribute loads and enhancing foundation stability (serving as a lightweight reinforcement).

5.Agriculture and Horticulture: Used as filtering layers in drainage ditches of greenhouses and farmlands to prevent soil particles from clogging pipes. They can also act as weed-proof isolation layers for crop cultivation to reduce weed growth.

In summary, relying on its versatile functions, polyethylene geotextiles are widely used across key fields including water conservancy, transportation, environmental protection, construction, and agriculture. It is not only a basic material to ensure the structural safety of projects (e.g., anti-seepage, anti-settlement) but also an important support to facilitate ecological protection (e.g., water purification, soil protection). Its application scenarios are still expanding with the upgrading of project demands, featuring remarkable practicality and adaptability.