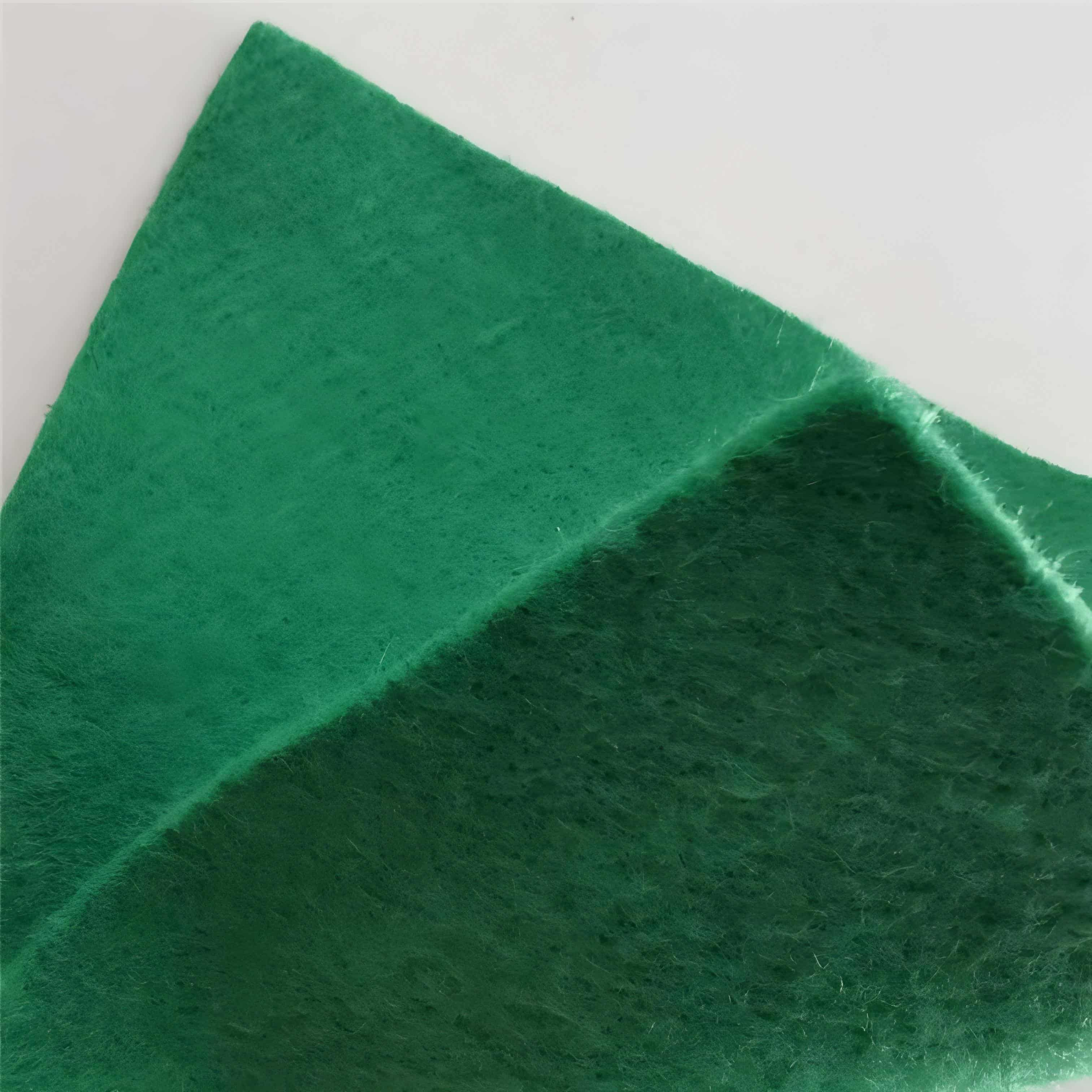

Geotextile for Waterproofing

1. Multifunctionality: It has multiple functions such as isolation, filtration, drainage, reinforcement, protection, and puncture prevention, which can meet the needs of different projects.

2. High cost-effectiveness: Lightweight, low-cost, and easy to construct, which can reduce the overall cost of the project.

3. Strong durability: after special treatment, it has good aging resistance, low temperature resistance and long service life.

4. Good environmental performance: Some geotextiles are made of biodegradable materials, such as polylactic acid (PLA) geotextiles, which can reduce post construction pollution.

Product Introduction:

Geotextile for Waterproofing is a type of sheet material made from synthetic fibers (such as polypropylene, polyester, polyethylene, etc.) or natural fibers (such as linen, cotton fibers, etc., which are less commonly used) through non-woven processes (such as needle punching, hydroneedling, thermal bonding), weaving processes (such as machine weaving, knitting) or other processing methods, which has water permeability, flexibility, and certain mechanical properties. It is not a traditional "fabric", but a functional material specifically designed for fields such as geotechnical engineering, water conservancy engineering, and transportation engineering. Its core function is to solve problems such as infiltration, filtration, reinforcement, and protection between soil and water, and between soil and structures in engineering. It is one of the indispensable key materials in modern civil engineering.

Core characteristics of geotextile

The characteristics of geotextiles revolve around their "functionality" and "engineering adaptability". Geotextiles made by different processes have slight differences in their features, but overall they share the following common characteristics:

1. Excellent permeability and filtration: This is one of the most fundamental characteristics of geotextiles. There are a large number of interconnected tiny pores (porosity usually ranging from 70% to 90%) inside, which can allow water and gas to pass smoothly, while also blocking the loss of small particles (such as sand and soil particles) in the soil with water flow, avoiding damage to engineering structures (such as dams and roadbeds) due to problems such as "pipe surge" and "soil flow". For example, the pore distribution of needle punched non-woven geotextiles is uniform, and the filtration accuracy can be controlled by adjusting the fiber fineness and needle punched density according to engineering requirements.

2. Stable mechanical properties: Geotextiles need to withstand loads such as soil pressure, external tension, and impact in engineering, thus possessing certain tensile strength, tear strength, burst strength, and creep resistance. Synthetic fibers (such as polypropylene) have high strength and moderate elongation, and through process optimization (such as the interweaving structure of warp and weft yarns in woven geotextiles and the fiber entanglement structure in non-woven geotextiles), geotextiles are less likely to break or deform under long-term stress. For example, the tensile strength of woven geotextile can reach 20-100kN/m, which can meet the reinforcement needs of high fill roadbeds.

3. Excellent environmental corrosion resistance: Due to long-term exposure to soil, water bodies (including fresh water, seawater, sewage) or outdoor environments, geotextiles need to resist chemical corrosion, biological erosion, and climate aging. Synthetic fiber itself has the characteristics of acid resistance, alkali resistance and salt resistance, and is not easy to be decomposed by microorganisms (such as bacteria and fungi). At the same time, by adding antioxidants, anti ultraviolet agents and other additives, its anti-aging ability can be further improved - in the conventional outdoor environment, the service life of high-quality geotextiles can reach 10-20 years, and longer in the buried environment.

4. Good flexibility and adhesion: Geotextile has a soft texture that can be folded and curled freely, making it easy to transport and construct; At the same time, it can tightly adhere to irregular soil surfaces or structural interfaces (such as slopes of dams, outer walls of pipelines), avoiding water leakage or soil loosening caused by interface gaps. For example, in slope protection engineering, flexible geotextiles can naturally spread along the slope terrain and form an overall protective layer with the soil.

5. Lightweight and easy to construct: The surface density of geotextile is usually between 100-800g/㎡, with a light weight per unit area and a single roll length of 50-100m. No large equipment is required during construction, only manual laying and splicing (through thermal bonding, stitching or overlapping) are needed, which is efficient and cost-effective. Compared to traditional sand and gravel filter layers and concrete protective layers, the construction period of geotextiles can be shortened by more than 30%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and hydropower engineering: This is one of the core application areas of geotextiles, mainly used for filtration, anti-seepage, protection, and drainage. For example, in dam construction, needle punched non-woven geotextiles are laid between the soil and sand on the upstream slope of the dam, which can filter river water, prevent soil particle loss, and discharge seepage inside the dam, avoiding landslides caused by high infiltration lines of the dam; In reservoir anti-seepage engineering, the composite use of geotextile and HDPE anti-seepage membrane can enhance the anti puncture ability of the anti-seepage membrane and prevent the membrane from being punctured by sharp soil. In addition, geotextiles are also used in scenarios such as river regulation, foundation drainage of hydropower plant buildings, and channel protection in irrigation areas.

2. Transportation engineering (highways, railways, airports): mainly used for roadbed reinforcement, drainage, and pavement protection. In the construction of highway subgrade, if the subgrade is a soft soil foundation, it is necessary to lay machine woven geotextile (or a composite product of geogrid and geotextile) to restrain soil deformation and reduce subgrade settlement through the tensile effect of geotextile; Laying geotextile between the base layer and sub base layer of the road can serve as a "barrier" to prevent fine particles from infiltrating the sub base layer and reduce the occurrence of reflective cracks on the road surface. In railway track engineering, geotextile is used as the drainage layer of the track bed to accelerate rainwater drainage and avoid steel rail corrosion caused by accumulated water in the track bed; In airport runway construction, geotextile can enhance the stability of the runway base and resist the impact load during aircraft takeoff and landing.

3. Municipal engineering: covering urban roads, underground pipelines, landfills, park landscapes, and other scenes. In urban underground comprehensive pipe gallery projects, geotextile is used as a filtering and drainage layer on the outer wall of the pipe gallery to prevent moisture from infiltrating the interior of the pipe gallery and protect the anti-corrosion layer on the outer wall of the pipe gallery; In landfill engineering, geotextile is a key component of the "anti-seepage system" and "leachate collection system" - geotextile laid above the anti-seepage membrane can prevent sharp objects from puncturing the anti-seepage membrane, and geotextile laid in the leachate collection ditch can filter garbage particles in the leachate and avoid blockage of the collection pipeline. In addition, geotextiles are also used for slope protection and water purification in artificial lakes and river treatment projects in urban parks.

4. Construction and mining engineering: In construction engineering, geotextile is used as the drainage layer for the basement roof to drain rainwater above the roof and prevent basement leakage; In foundation pit support engineering, the combination of geotextile and sandbags can be used to construct temporary retaining walls, which play a protective and drainage role. In mining engineering, geotextiles are used for filtering and reinforcing tailings dams - tailings dams are important facilities for storing slag in mines. Laying geotextiles can prevent tailings particles from flowing away with rainwater, while also draining the seepage inside the dam body and avoiding dam failure; In addition, geotextile is also used for underground roadway support in coal mines to enhance the stability of the surrounding rock of the roadway.

5. Agriculture and Ecological Engineering: In the field of agriculture, geotextiles are used to protect irrigation channels in farmland, prevent soil erosion on channel slopes by water flow, reduce channel leakage, and improve irrigation efficiency; In greenhouse construction, geotextile can serve as a moisture-proof layer for the ground inside the greenhouse, improving the humidity environment inside the greenhouse. In ecological engineering, geotextile is used for riverbank ecological slope protection - compared with traditional concrete slope protection, geotextile (especially ecological geotextile) can allow plant roots to penetrate, forming a composite protective layer of "vegetation geotextile soil", which not only plays a role in slope protection, but also restores the ecological environment of the riverbank; In addition, geotextiles are also used in wetland restoration, soil erosion control and other scenarios to help restore ecosystem functions.

In summary, although geotextiles may seem simple, they are the crystallization of modern engineering technology. It has successfully solved numerous thorny problems in traditional engineering with its multifunctionality, economy, and reliability, becoming an unknown "hero" behind the construction of our safe, convenient, and sustainable living environment.