Sediment Dewatering Bags

1. High-efficiency dewatering: Unique permeable filter cloth structure quickly separates moisture from sludge, significantly reducing the moisture content of the sludge cake.

2. Solid waste interception: Precisely intercepts solid particles such as silt and sediment, preventing secondary pollution and meeting environmental protection requirements.

3. Convenient and easy to use: No large equipment required; natural sedimentation and dewatering after loading; foldable for storage after use, saving labor and effort.

4. Durable and economical: Tear-resistant and acid/alkali-resistant, reusable multiple times, reducing the overall cost of sludge treatment.

Products Introduction:

Sediment Dewatering Bags are efficient and environmentally friendly geotechnical containers designed specifically for the treatment of water bodies containing sediment. They are made from high-strength polypropylene (PP) or polyester (PET) filaments and woven using special techniques to create bag like structures with high permeability and retention. The core principle is to use the "filtration interception" effect of the bag fabric to pump sediment containing sewage (such as river silt, construction site wastewater, and mine tailings) into the bag. The water is quickly discharged through the pores of the fabric, and solid particles such as sediment are intercepted in the bag, achieving efficient separation of mud and water. This product does not require complex equipment or chemical agents, and is suitable for sediment treatment scenarios of different scales. It is a key tool for achieving sediment reduction and water resource recycling in projects such as river dredging, construction site water control, and ecological restoration.

Product Features:

1. Efficient mud water separation and fast dehydration speed: The bag fabric adopts precision weaving technology, and the pore size is precisely controlled within 0.1-0.5mm, which can efficiently intercept sediment particles (with a retention rate of over 95%) and ensure rapid water infiltration and discharge. Under normal operating conditions, each cubic meter of dewatering bag can complete the separation of mud and water within 24-72 hours, reducing the moisture content of sediment in the bag from 80% -90% to 40% -60%, significantly reducing the volume of sediment, and accelerating the subsequent cleaning or resource utilization efficiency.

2. Physical filtration is pollution-free and environmentally friendly: The entire process relies on the principle of physical filtration to achieve dehydration, without the need to add chemical agents such as coagulants and dehydrators, avoiding secondary pollution of water bodies, soil, and ecological environment caused by chemical residues. At the same time, the separated clean water meets the standard of water quality and can be directly reused for dust reduction, irrigation, or discharged into natural water bodies on construction sites, meeting the requirements of "zero pollution and recyclability" in environmental engineering.

3. High strength and wear resistance, strong durability: The raw materials are made of anti-aging and stretch resistant polymer fibers, which are reinforced by double line sewing. The tensile strength of the bag body can reach 20-50kN/m, and the tear resistance is excellent. During loading, stacking, and transportation, it can withstand the weight of sediment and external pressure, and is not easily damaged; And it can withstand harsh environments such as acid and alkali, salt spray, etc. (such as coastal reclamation and mine tailings treatment), with a service life of 2-5 years, and supports multiple cycles of use.

4. Flexible adaptation and easy operation, with a wide range of applicable scenarios: the product specifications are diverse, with capacities ranging from 1m ³ to 50m ³, and can be flexibly selected according to the project scale; The bag body is lightweight and easy to transport, and no professional equipment is required for laying and installation. Simply connect the water pump to start the dehydration operation. At the same time, it can be stacked or laid flat according to the site terrain (such as riverbanks, construction site depressions), suitable for narrow spaces or large-scale work scenarios, reducing construction difficulty and costs.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

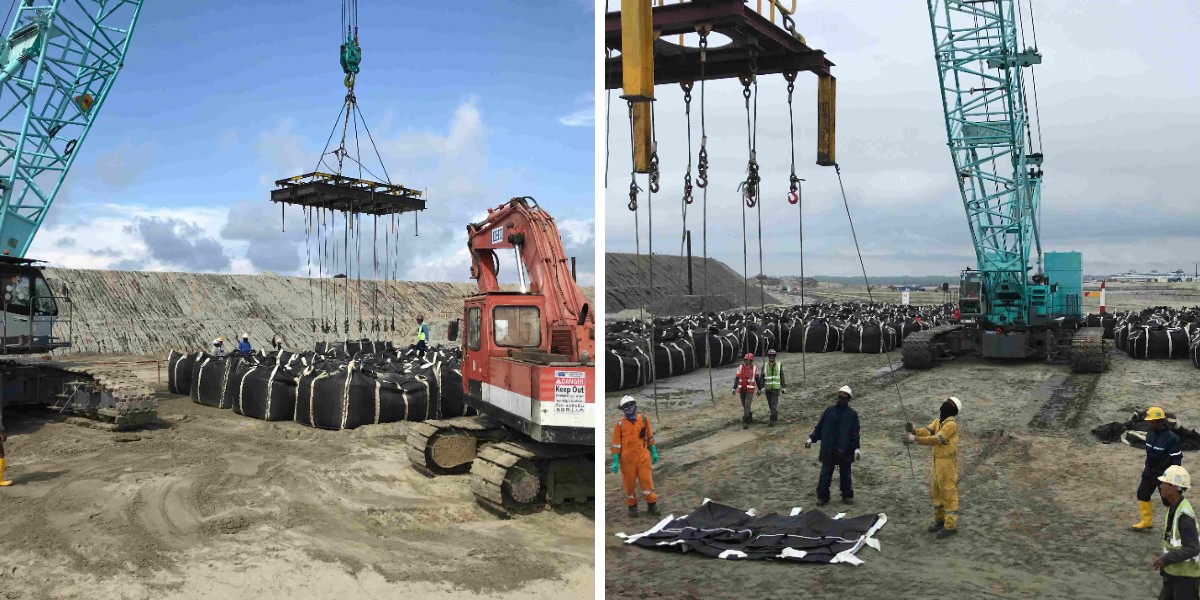

Product Applications:

1. River and lake dredging project: In urban inland river and landscape lake dredging projects, the high moisture content silt excavated by dredging ships is pumped into dewatering bags to quickly separate water and reduce the volume of silt (with a reduction rate of over 50%), facilitating subsequent cleaning or harmless treatment; The separated clear water is discharged back into the river channel to avoid the diffusion of turbidity during the dredging process.

2. Water treatment for construction and municipal construction sites: The sediment containing wastewater generated from building foundation pit dewatering and municipal road construction can be filtered through dewatering bags, and the clean water can be recycled for site watering, dust reduction, and concrete curing. The sediment is solidified in the bags to avoid direct discharge of wastewater and pollution of municipal pipelines or surrounding water bodies, which meets the requirements of environmental protection construction on construction sites.

3. Tailwater treatment of mines and quarries: Tailwater slurry and washing wastewater generated by coal mines, metal mines, and quarries can be treated with dewatering bags to intercept solid particles such as tailings sand and stone powder, preventing them from blocking rivers or polluting soil; The separated clean water can be reused in the ore washing process, achieving water resource recycling and reducing water costs for enterprises.

4. Ecological restoration and land reclamation: In coastal wetland restoration and land reclamation projects, it is used to treat nearshore sediment laden water bodies, intercept sediment to form a stable land base; Or in the vicinity of reservoirs and drinking water sources, treat the sediment in the inflow tributaries, reduce reservoir siltation, and ensure the safety of drinking water source water quality.

Sediment Dewatering Bags have become the preferred solution for sediment treatment engineering due to their core advantages of efficient dewatering, environmental friendliness, durability, and flexibility. It can not only quickly achieve mud water separation, reduce sediment volume, and lower transportation costs, but also avoid chemical pollution, which meets the core requirements of current environmental protection engineering; At the same time, its flexibility and ease of operation can cover diverse scenarios from small construction sites to large-scale ecological projects, balancing efficiency and economy. Whether it is solving the problem of reducing capacity in river dredging, realizing the recycling of construction site wastewater, or ensuring the environmentally friendly discharge of mine tailings, this product can provide reliable and efficient solutions, and is an important tool for promoting green construction and ecological protection in fields such as water conservancy, municipal engineering, and mining.