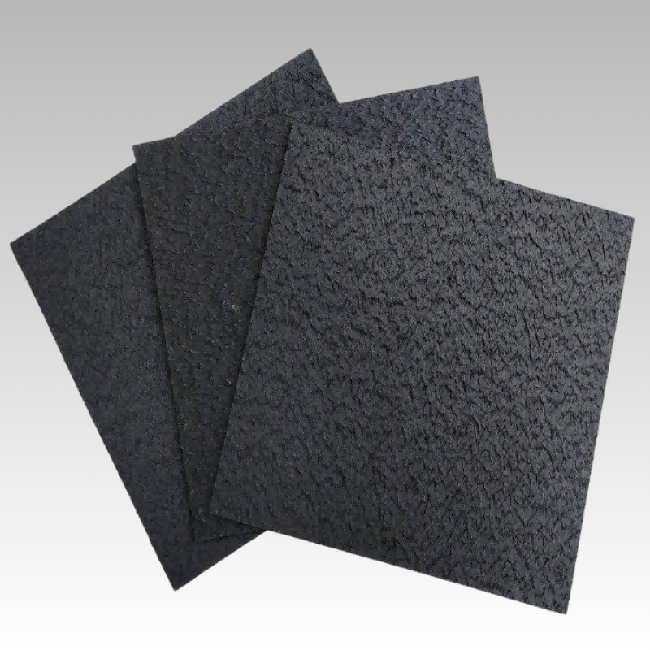

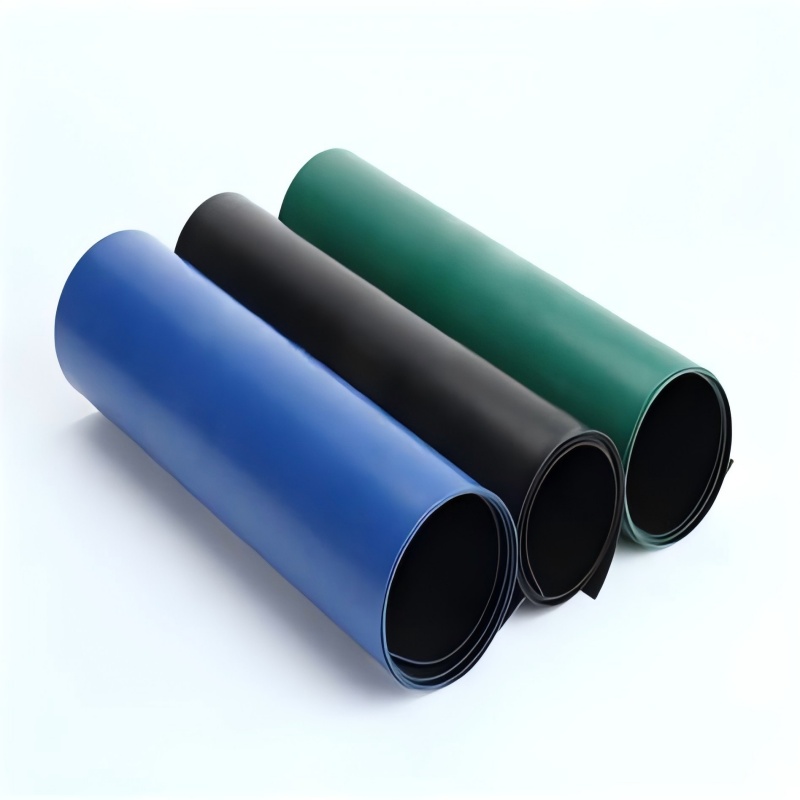

HDPE Geomembrane Sheet

1.Anti-seepage performance:

The coefficient of permeability is < 10⁻¹³ cm/s, almost impermeable to water.

2.Chemical corrosion resistance:

Resistant to erosion from acids, alkalis, oils, salts, etc.

3.Anti-aging:

Added with anti-UV agents, the outdoor service life can reach more than 10 years.

4.High tensile strength:

Adaptable to foundation settlement or deformation.

5.Environmental protection and non-toxic:

Complies with drinking water engineering standards (e.g., HDPE virgin material membrane).

Product Introduction:

HDPE Geomembrane Sheet is a kind of anti-seepage material made from polymer materials (such as HDPE, LDPE, PVC, LLDPE, etc.), featuring an extremely low coefficient of permeability. It is mainly used to isolate the penetration of liquids or gases.

Temperature Resistance:It exhibits excellent heat resistance and cold resistance, with a broad operating temperature range. It can be used in environments spanning from high temperatures of 110℃ to low temperatures of -70℃.

Weather Resistance :It possesses strong anti-aging properties, enabling it to maintain its original performance even when exposed outdoors for prolonged periods.

Flexibility:As a flexible waterproof material, the geomembrane can adapt to certain degrees of uneven geological settlement.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1.Environmental Engineering

Landfills, wastewater treatment ponds, hazardous waste containment.

2.Water Conservancy Projects

Reservoirs, canals, dam liners; artificial lakes, decorative water features.

3.Agriculture

Aquaculture ponds (fish/shrimp), irrigation ponds, biogas digesters.

4.Mining

Tailings storage, heap leach pads, red mud disposal sites.

5.Municipal/Transportation

Tunnel waterproofing, roadbed separation.

Choosing a geomembrane means opting for a reliable anti-seepage solution and ensuring long-lasting project quality. Whether it's for large-scale infrastructure construction or small-scale agricultural facility renovations, geomembranes can meet diverse requirements with their excellent performance, safeguarding the long-term stable operation of projects.