Cement Canvas

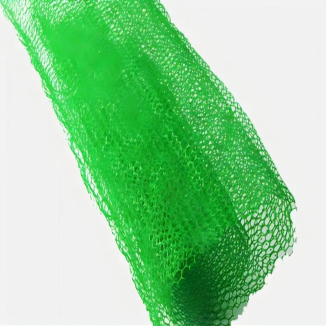

1.Lightweight & Flexible:

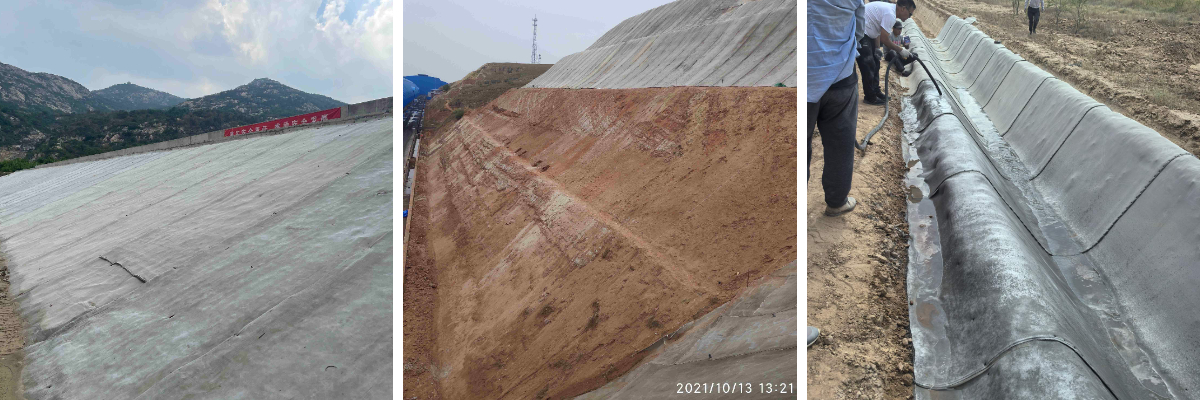

Roll-based design, can be cut and folded to fit complex terrain (e.g., slopes, trenches).

2.High Strength:

After curing, compressive strength ≥20 MPa with excellent tear resistance.

3.Eco-Friendly & Durable:

Low-carbon material, UV-resistant, corrosion-resistant, and a service life exceeding 50 years.

4.Waterproof & Fireproof:

Impermeable (IP67-rated), with a Class A1 fire rating (non-combustible).

Product Introduction:

Cement Canvas is a revolutionary flexible composite material that combines the strength of traditional concrete with the convenience of textiles, forming a "ready-to-use" hardened fabric. Simply by adding water, it rapidly solidifies into a durable, waterproof, and fire-resistant layer, significantly reducing construction time and labor costs.

Cement Canvas utilizes a three-dimensional fibrous composite structure woven from polyethylene and polypropylene filaments as its base material. The surface is pre-impregnated with a specially formulated dry concrete mixture, which undergoes a hydration reaction when exposed to water. The bottom surface is coated with a polyvinyl chloride (PVC) waterproof layer, offering additional waterproof protection.

Simple Laying: It has low requirements for foundation treatment. Just lay the cement blanket in the desired position and water it to trigger the hydration reaction.

Rapid Solidification and Molding: Once the hydration reaction is triggered by watering, it can harden to reach 80% of the strength within 24 hours.

Core Features

Convenient Construction: It can be coiled for transportation and laid manually. It reaches 80% of its strength 24 hours after watering, eliminating the need for mixing and formwork.

Diverse Performance: Waterproof (PVC layer), fireproof (flame - retardant), impact - resistant, and highly weather - resistant. It can adapt to complex terrains such as curved surfaces and slopes.

Environment - friendly and Low - carbon: The material consumption is 95% less than that of traditional concrete, with a low alkali content and low carbon emissions.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

1.Infrastructure Projects: Canal lining, slope protection, tunnel reinforcement.

2.Emergency Repairs: Road pothole patching, rapid military shelter construction.

3.Environmental Projects: Artificial lake waterproofing, landfill cover systems.

4.Agriculture/Landscaping: Drainage ditches, water storage ponds, firebreaks.

Cement Canvas no professional equipment is required. It can be laid by a single person, 10 times faster than traditional concrete, and forms quickly. It is provided in rolls or in bulk, making transportation, loading/unloading and installation convenient.