Geotextile Fabric for Rip Rap

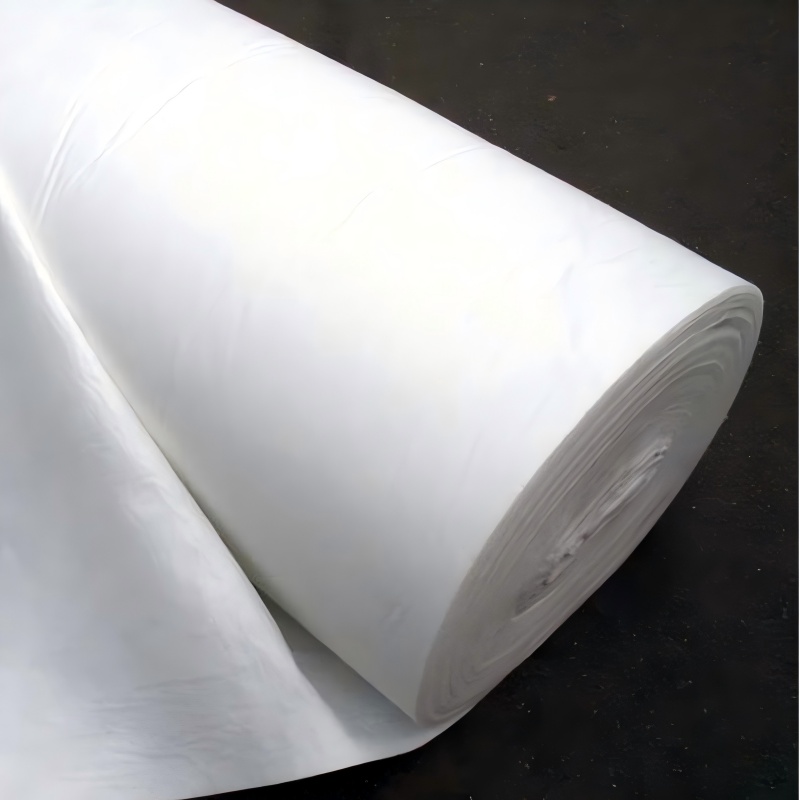

1. Easy Construction and High Efficiency: Geotextiles are supplied in the form of rolls, which are lightweight, easy to lay, and can greatly shorten the construction period and reduce labor.

2. Excellent Overall Performance: As a continuous integral material, it can transmit and distribute stress more evenly, reducing uneven settlement.

3. Easy to Control Quality: As an industrialized product, its performance indicators are stable and its quality is far superior to natural materials such as sand and gravel selected on site.

4. Reduce Engineering Costs: It can usually replace traditional structures such as sand and gravel filters and drainage ditches, saving material and transportation costs, and reducing land occupation.

5. Corrosion Resistance and Resistance to Biological Damage: Synthetic fiber materials are not easily decomposed, moldy, or invaded by insects and ants, making them suitable for long-term use in various harsh environments.

Product Introduction:

Basic Properties

Geotextile Fabric for Rip Rap is mainly made of polypropylene (PP) and polyester (PET) as core raw materials, adopting staple fiber needle-punched non-woven and filament woven processes as the mainstream. Its conventional grammage ranges from 200 to 800 g/㎡, with the longitudinal and transverse tensile strength of ≥10-50 kN/m. It features UV resistance, acid and alkali resistance, and anti-microbial degradation, and is suitable for rip rap project environments such as fresh/brackish water areas and soil embedding conditions.

Core Functions

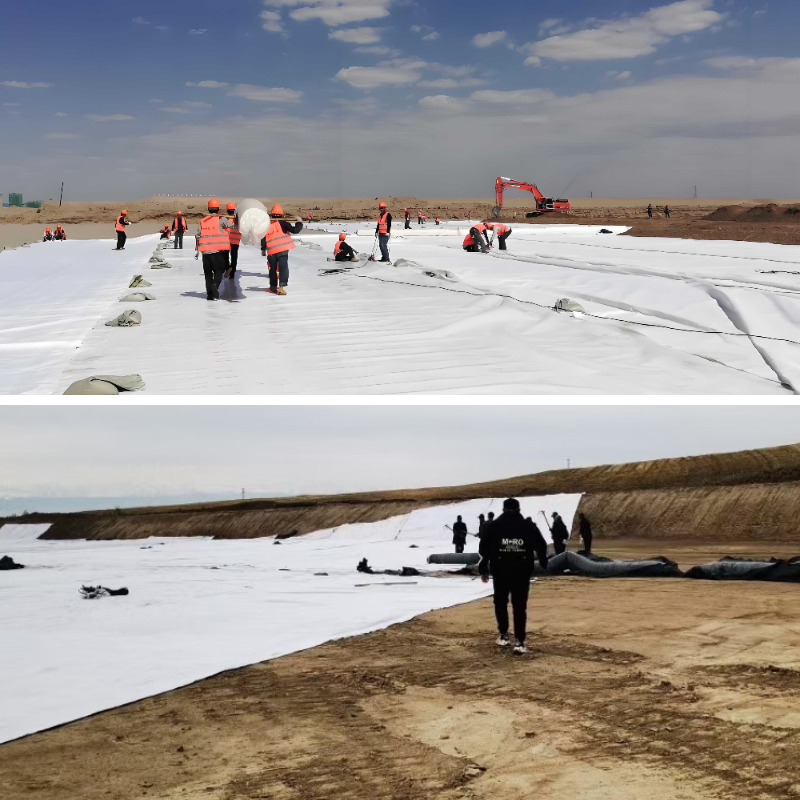

It fundamentally addresses the problems of soil particle loss, slope sliding and foundation damage in rip rap revetment projects, and integrates four core functions: separation (isolating rip rap and soil to prevent silting and collapse), filtration (allowing water penetration while retaining soil to maintain soil stability), reinforcement (distributing loads to improve the shear resistance of slopes), and cushioning protection (alleviating the impact of rip rap and water flow scouring). It thus forms a three-layer protection system for revetments.

Key Features

As a custom geotextile for rip rap projects, it boasts outstanding tear and puncture resistance, withstanding construction rolling and rock impact. It is resistant to harsh environments such as tides and wet-dry alternation, with a service life of 15 to 30 years. It features controllable water permeability without silting, with pore size matching that of soil and rip rap layers. Lightweight and easy to lay, it is adaptable to complex terrains and enables efficient construction. It offers high cost performance by reducing rip rap consumption, and achieves a rigid-flexible combination with excellent synergy with rip rap layers, making it suitable for various rip rap revetment projects of rivers, coastal areas and slopes.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. In the field of transportation infrastructure

Highway/railway subgrade: laying needle punched geotextile between subgrade filling and roadbed soil to achieve soil isolation and avoid the decrease in subgrade strength caused by the mixing of different particle soils; At the same time, the filtering effect of geotextile can prevent soil erosion caused by rainwater erosion, while the drainage function accelerates the discharge of accumulated water inside the roadbed, reduces pore water pressure, and avoids roadbed softening and settlement. For soft soil foundation sections, woven geotextiles can be laid as reinforcement layers to enhance the bearing capacity of the roadbed and reduce post construction settlement (such as in the construction of highways in soft soil areas along the southeast coast of China, geotextile reinforced roadbeds can control settlement within 5cm).

Road maintenance and repair: In the renovation of old road surfaces, laying geotextile (or geogrid composite fabric) between the asphalt surface layer and the base layer can reduce the upward reflection of base cracks to the surface layer (i.e. "reflection cracks"), and extend the service life of new road surfaces; In temporary construction access roads, laying heavy geotextiles can enhance the bearing capacity of the road, avoid damage caused by vehicle crushing, and protect the original ground soil. After construction, the geotextiles can be recycled and reused.

Bridge and tunnel engineering: Laying geotextile in the backfill soil behind the bridge abutment can reduce the settlement difference between the abutment and the roadbed (the "bridgehead jumping" problem) and improve driving comfort; Laying geotextile behind the tunnel lining can serve as a drainage layer, directing water seepage from the lining into drainage pipes to prevent water accumulation inside the tunnel and protect the lining structure from water seepage erosion.

2. Water conservancy and hydropower engineering

Reservoir/embankment construction: Laying geotextile (often combined with geomembrane) on the upstream slope of the embankment as an anti-seepage protective layer to prevent soil loss caused by wave erosion; Laying vertical or horizontal geotextile drainage layers inside the dam can dissipate the pore water pressure in the soil and avoid piping and landslides caused by excessive seepage pressure in the dam (such as the extensive use of needle punched geotextile as a drainage filter layer in the dam reinforcement project of the Three Gorges Reservoir in China); Laying geotextile on the upper and lower layers of the anti-seepage membrane of the dam can protect the anti-seepage membrane from being pierced by sharp stones, filter out seepage water, and prevent soil loss under the membrane.

River/channel management: In river slope management, geotextile is laid and then covered with soil and vegetation to form an ecological protection system of "geotextile+vegetation". This can not only reinforce the slope, prevent river bank collapse caused by water flow erosion, but also improve the ecological environment of the river; In irrigation channels, geotextile can be used as a filter layer, laid at the bottom and slopes of the channel, to avoid channel leakage (reduce water waste), and prevent soil particles from flowing away with water flow, thus extending the service life of the channel.

Port and Coastal Engineering: In the construction of breakwaters at port terminals, heavy geotextiles (such as woven geotextiles) are laid to resist wave impacts and protect the embankment filling materials; In coastal protection engineering, geotextile can be combined with sandbags and stones to form a flexible protective structure that adapts to soil deformation caused by tidal changes on the coast and avoids cracking of rigid revetments (such as concrete revetments) due to wave impact.

3. Environmental Protection Engineering

Landfill site: In the anti-seepage system of a landfill site, geotextile plays a key role - laying geotextile on top of high-density polyethylene (HDPE) anti-seepage film as a protective layer to prevent sharp debris (such as metal and glass) from puncturing the anti-seepage film; Lay geotextile underneath the anti-seepage membrane as a filter layer to filter the groundwater at the bottom of the landfill site, avoiding soil particles from blocking the seams of the anti-seepage membrane and protecting the membrane body from sharp objects on the foundation; In addition, geotextile can be used as a filter layer in the leachate collection system of landfills to filter out garbage debris in the leachate and prevent blockage of the collection pipeline.

Wastewater treatment and solid waste disposal: Laying geotextiles on the bottom and walls of industrial wastewater treatment tanks can enhance the anti-seepage properties of the tank structure and protect the anti-seepage layer from corrosion by wastewater; Laying geotextile as a drainage filter layer in tailings ponds (mining solid waste accumulation sites) can accelerate the discharge of water from tailings water, promote tailings consolidation, reduce the risk of tailings dam failure, and prevent tailings particles from flowing away with water and polluting surrounding soil and water bodies.

Soil remediation engineering: In the remediation of heavy metal contaminated soil, laying geotextile can serve as an isolation layer to block the contact between contaminated soil and uncontaminated soil, avoiding the spread of pollution; At the same time, the permeability of geotextiles can be combined with the penetration of remediation agents (such as activated carbon and microbial agents) to improve soil remediation efficiency.

4. Construction and Municipal Engineering

Building foundation and foundation pit: In the deep foundation pit support of high-rise buildings, laying geotextile as a drainage layer can accelerate the discharge of groundwater in the surrounding soil of the foundation pit, reduce the water level of the foundation pit, and avoid foundation pit collapse; In soft foundation treatment (such as fill foundation), laying geotextile as a reinforcement layer can enhance the overall strength of the foundation, reduce uneven settlement of the foundation, and avoid cracking of building walls.

Underground pipe gallery and pipeline engineering: laying geotextile on the outside of the underground comprehensive pipe gallery can serve as a protective layer to protect the pipe gallery structure from sharp objects in the surrounding soil, while filtering groundwater and avoiding leakage at the pipe gallery interface; In the laying of water supply and drainage pipelines, adding geotextile to the backfill soil around the pipeline can reduce the pressure of soil on the pipeline, prevent pipeline corrosion, and extend the service life of the pipeline.

Municipal greening and landscape engineering: In roof greening and vertical greening projects, geotextile is laid as a filtering layer to separate planting soil and drainage layer, avoiding planting soil particles blocking drainage holes and preventing plant roots from penetrating the drainage layer, protecting the roof or wall structure; In the construction of urban artificial lakes and landscape rivers, geotextiles can be used as anti-seepage protective layers, combined with geomembranes, to prevent lake water leakage and protect the anti-seepage membrane from being damaged by stones and plant roots at the bottom of the lake.

5. Agriculture and Ecological Engineering

Agricultural water conservation and soil and water conservation: Laying geotextiles in irrigation channels can reduce channel leakage and improve water resource utilization (such as in irrigation channels in arid northwest regions, the use of geotextiles can reduce leakage by more than 80%); Laying geotextile along contour lines in terraced fields and sloping fields can slow down the speed of rainwater erosion, prevent soil loss, while maintaining soil moisture and increasing crop yields.

Ecological restoration and soil and water conservation: In mining greening and barren mountain management projects, laying geotextiles (often combined with ecological blankets and grass seeds) can fix the slope soil, prevent soil erosion, and provide a stable growth environment for grass seed germination, accelerating vegetation recovery; In the construction of river ecological buffer zones, geotextiles can be used as base materials, combined with aquatic plant planting, to build waterfront ecosystems, purify water quality, and protect aquatic habitats.

Geotextile fabric is a versatile engineering material with extensive applications across five core fields, playing an irreplaceable role in ensuring project stability, improving engineering quality, and reducing construction and maintenance costs. In transportation infrastructure, it is widely used in highway/railway subgrades, road maintenance, and bridge and tunnel projects to achieve soil separation, filtration, reinforcement, and drainage, effectively solving problems such as subgrade settlement, reflection cracks, and bridgehead jumping. In water conservancy and hydropower engineering, it serves key functions in reservoir/embankment anti-seepage, river/channel management, and port and coastal protection, preventing soil erosion, seepage damage, and rigid structure cracking. In environmental protection engineering, it is crucial for landfill anti-seepage, wastewater treatment, solid waste disposal, and soil remediation, blocking pollution spread and protecting the ecological environment. In construction and municipal engineering, it assists in building foundation stability, underground pipe gallery protection, and municipal greening, avoiding structural damage and ensuring project durability. In agriculture and ecological engineering, it contributes to water conservation, soil and water conservation, and ecological restoration, improving water resource utilization and promoting vegetation recovery. Throughout all these applications, geotextile fabric exerts its core functions of separation, filtration, reinforcement, drainage, and cushioning protection in a targeted manner, adapting to diverse engineering scenarios and effectively addressing key engineering pain points.