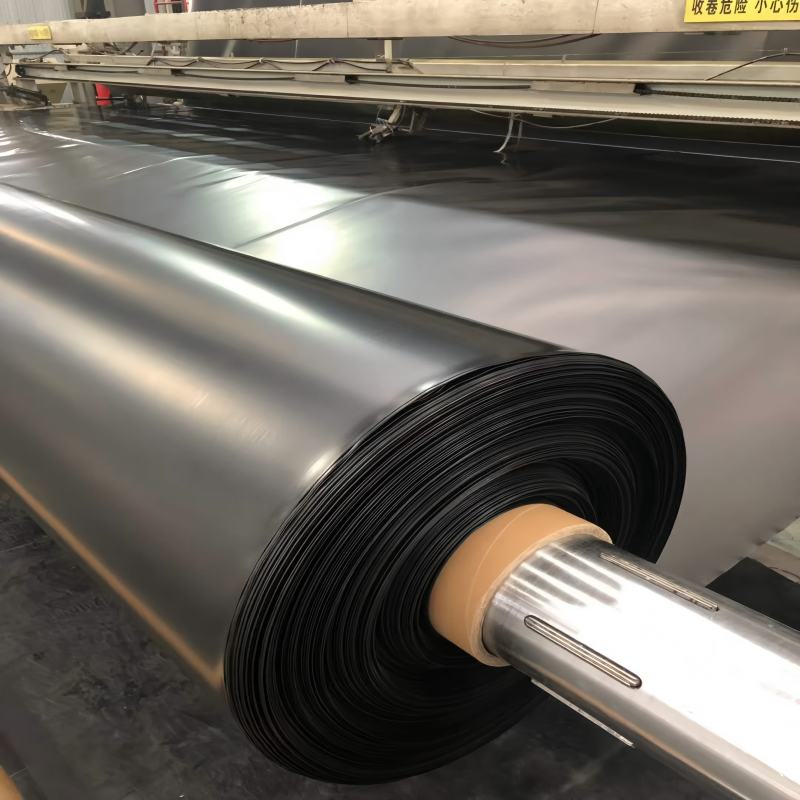

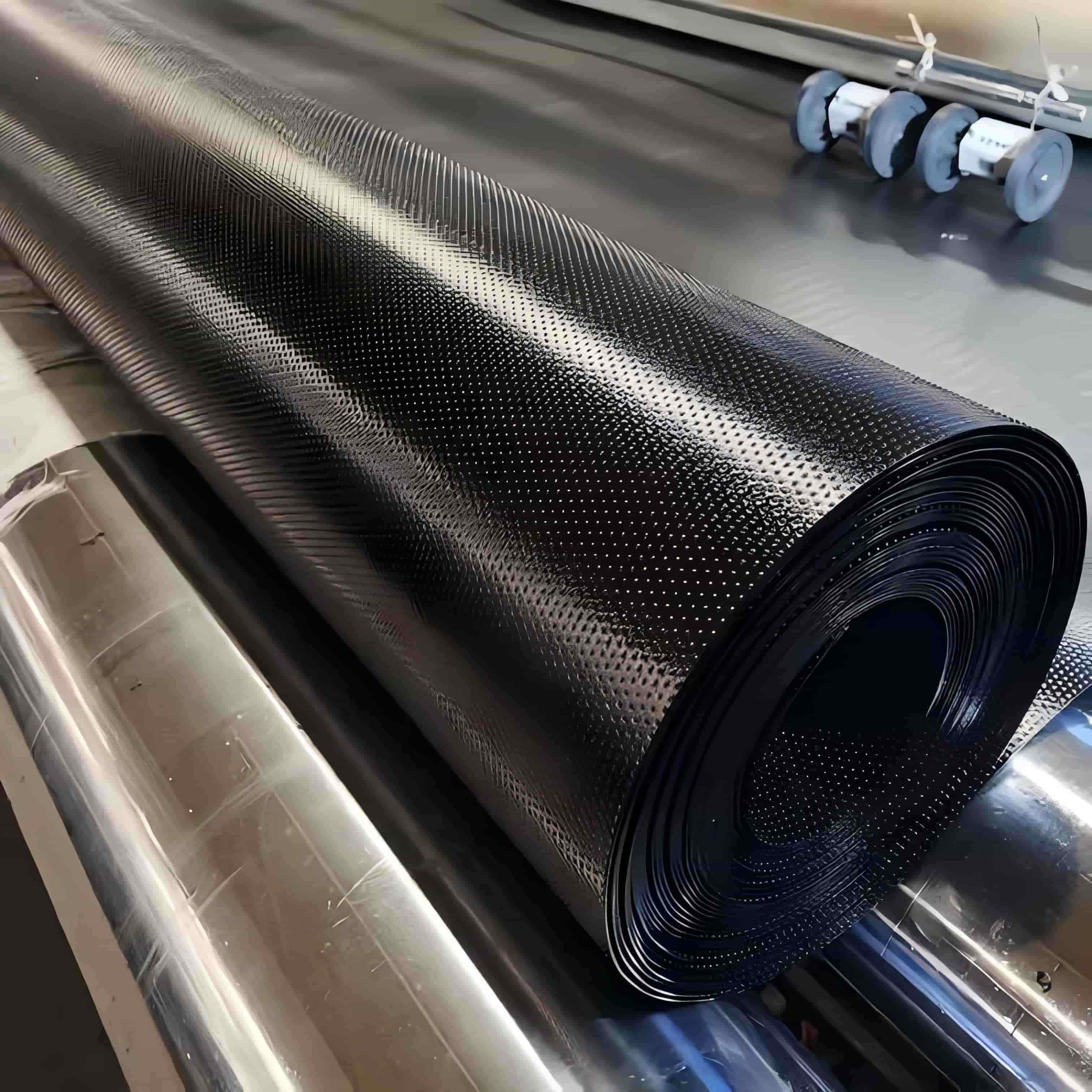

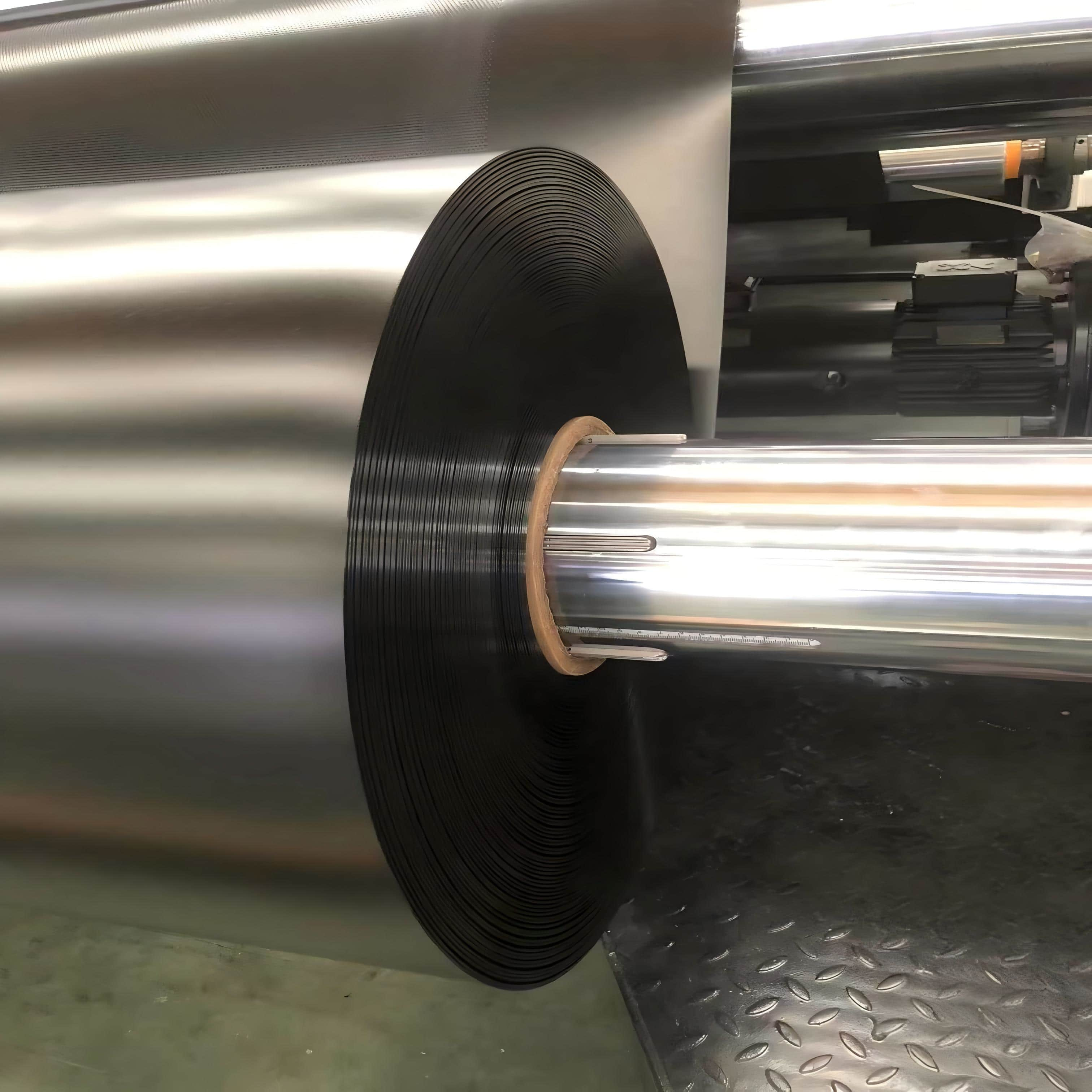

Polyethylene Geomembrane

• It has outstanding mechanical properties, high tensile strength, good toughness, puncture resistance, deformation resistance, and can adapt to foundation settlement.

• It has excellent anti-seepage performance, a very low coefficient of permeability, and a remarkable effect in blocking liquid leakage.

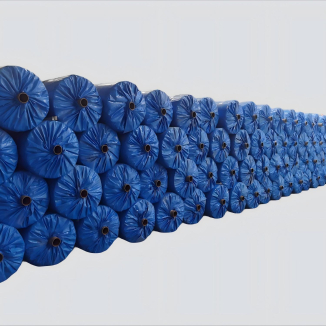

• It has a long lifespan, low construction cost, outstanding cost-effectiveness in large-scale projects, and can be recycled and reused.

• The material is non-toxic and harmless, does not pollute water and soil, can be recycled after being discarded, and meets environmental protection requirements.

• It has strong environmental adaptability, can resist high and low temperatures, and is resistant to ultraviolet aging.

Product Introduction:

Polyethylene Geomembrane is a flexible anti-seepage material made from high-density polyethylene (HDPE) resin through extrusion-calendering or blow-molding processes. It features excellent impermeability, chemical corrosion resistance, and environmental stress cracking resistance.As a geosynthetic material with functions such as anti - seepage, isolation, and reinforcement, geomembrane plays a crucial role in multiple engineering fields.

Core Anti-seepage Properties

Superior Weather Resistance

Chemical Inertness

Convenient Construction

Long Service Life

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

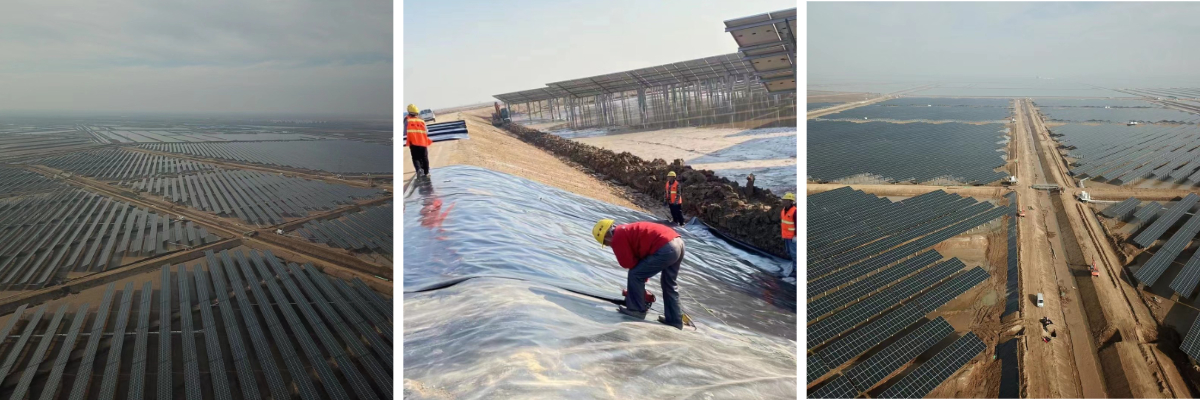

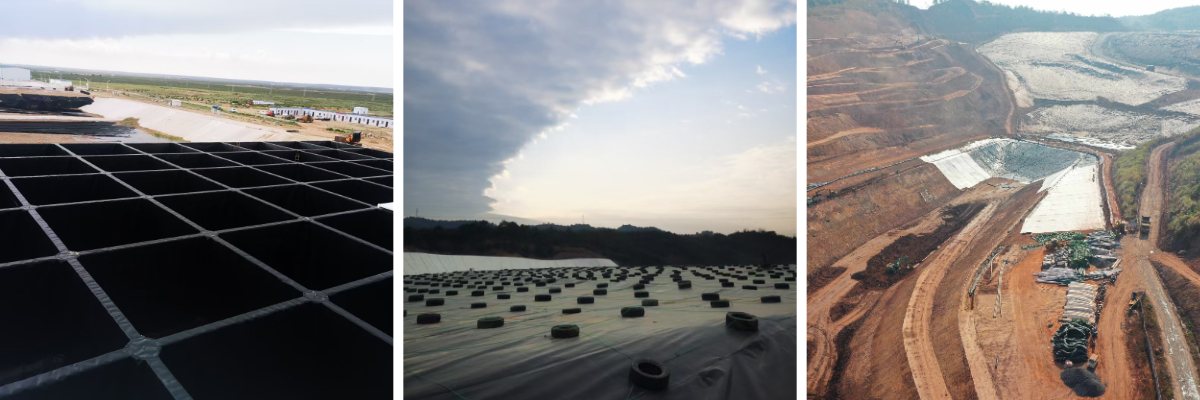

Product Applications:

1.Water Conservancy and Agricultural Engineering

Anti-seepage for reservoirs/irrigation channels: Replaces clay linings to reduce water resource loss and improve irrigation efficiency.

Aquaculture: Constructs pond anti-seepage membranes to maintain water levels and prevent eutrophication pollution.

Artificial wetlands: Serves as an anti-seepage base to ensure the water purification function of wetland systems.

2.Construction Engineering

Waterproofing for underground projects: Seepage prevention for tunnels and basement roofs to avoid structural damage from moisture.

Roof greening: Lightweight anti-seepage layer that balances drainage and plant root protection.

Artificial lakes/landscape water features: Creates leak-free water bodies to reduce water replenishment costs.

3.Special Industrial Scenarios

Chemical Plant Flooring: Acid-resistant flooring anti-seepage layer to prevent chemical leakage and pollution.

Electrolytic Cell Linings: Blocks electrolyte leakage to extend equipment service life.

4.Environmental Protection and Municipal Engineering

Landfills: Used as the base and cover anti-seepage layer to prevent leachate from contaminating groundwater.

Sewage Treatment Pools: Block sewage leakage to protect surrounding soil and water sources.

Hazardous Waste Sealing: Applied in high-risk scenarios such as hazardous waste temporary storage warehouses and nuclear waste isolation pools.

5.Mining and Energy Engineering

Tailings Pond Seepage Prevention: Prevents leakage of heavy metal solutions to reduce environmental pollution risks in mines.

Oil Storage Tank Areas: Serves as a secondary seepage prevention layer to intercept oil leakage and diffusion.

Red Mud Disposal Sites: Isolates highly alkaline waste residues to protect the surrounding ecological environment.

6.Transportation Engineering

Subgrade Seepage Prevention: Waterproof layers for highway and railway subgrades to prevent frost heave and mud boiling diseases.

Slope Erosion Control: Covers loose slopes to reduce landslides caused by rainwater erosion.