Using Geotextile Fabric in Livestock Operations

Mud prevention: Drains accumulated water, keeps pens dry, and reduces livestock slips.

Weed control: Reduces weeding effort and costs, preventing herbicide damage to livestock.

Site stability: Resists trampling and prevents soil compaction, extending the life of pens and other facilities.

Disease reduction: Reduces mixing of excrement with soil, reducing disease transmission.

Feed protection: Spreads on the bottom of feed storage areas to isolate moisture and prevent feed mold.

Product Introduction:

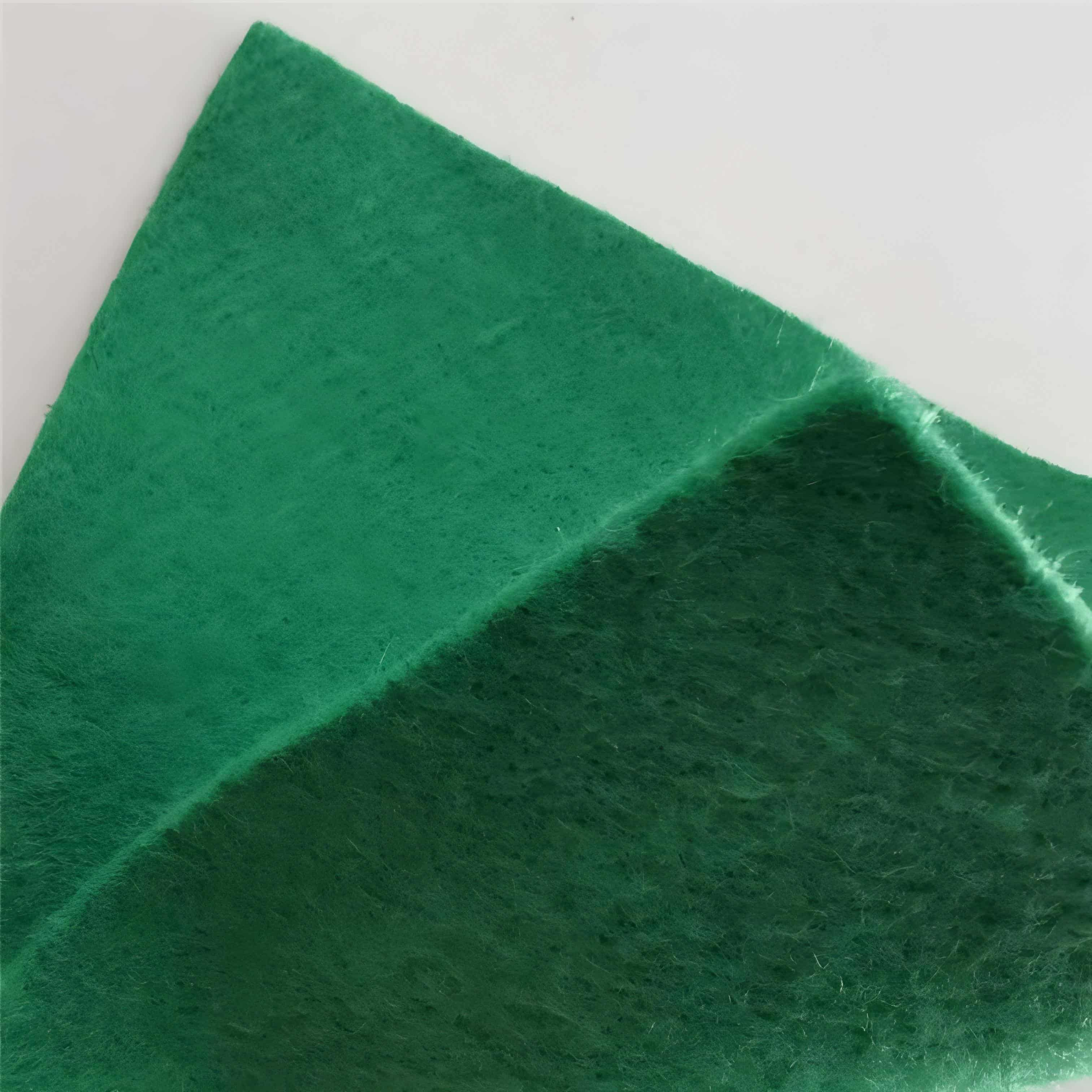

Using Geotextile Fabric in Livestock Operations are functional, environmentally friendly materials developed specifically for livestock operations, such as farms and pastures. Made from high-strength polyester and polypropylene fibers through needle-punching and weaving processes, they combine durability, breathability, and filter properties. They are widely applicable to key areas such as pen floors, feeding areas, livestock passages, feed storage areas, and manure disposal areas, providing a comprehensive solution for livestock production.

This product exhibits excellent tensile and abrasion resistance, withstanding the frequent trampling of livestock and the pressure of mechanical operations without tearing or deforming. Furthermore, its unique fiber structure effectively channels liquids such as rainwater and urine, quickly draining accumulated water while preventing soil particles from escaping with water, preventing mud and soil compaction, and keeping the surface dry and clean for a long time. In addition, the product has excellent barrier properties. When laid on the ground, it can block the light and nutrients required for weed growth, reducing the cost of manual weeding and eliminating the need for chemical herbicides, thus avoiding potential harm to livestock health from the source. When laid at the bottom of the feed storage area, it can isolate underground moisture, prevent feed from getting damp and mildewing, and reduce feed loss and the risk of livestock digestive tract diseases.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Pen Flooring

In pens for livestock such as pigs, beef cattle, and sheep, geotextiles are laid directly on the ground base (optionally with a crushed stone layer for enhanced drainage), replacing traditional cement paving or bare soil. Their breathable and hydrophobic properties allow urine and flushing water to drain quickly from the pen, preventing chronic moisture from breeding bacteria and reducing the incidence of hoof diseases (such as foot rot) and skin diseases. Furthermore, their soft fiber material cushions the pressure of standing and lying animals, enhancing comfort. This material is particularly suitable for environmentally sensitive areas such as farrowing pens and calf nurseries, while also reducing the risk of joint injuries caused by hard surfaces.

2. Livestock Passageways and Playgrounds

Passageways connecting pens, feeding areas, and milking parlors, as well as open areas where livestock roam freely, are areas of high traffic. Laying geotextiles here, with their tensile and abrasion-resistant properties, can distribute the pressure generated by the frequent trampling of livestock (especially large animals like dairy cows and beef cattle), preventing soil compaction and hardening. Even during the rainy season, this prevents water accumulation and mud in the passage, ensuring safe passage for livestock and reducing slip and fall injuries. It also minimizes ground damage caused by vehicles (such as feed trucks and manure trucks), extending the service life of the passage and reducing subsequent maintenance and renovation costs.

3. Feed Storage and Silage Areas

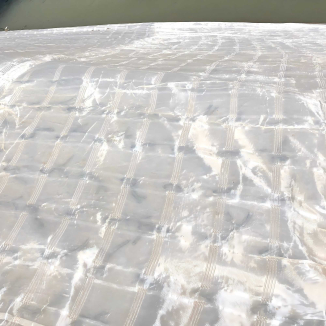

Geotextiles can be used in two ways in feed storage silos, hay storage areas, and silo pits: First, they can be laid on the floor of the storage area to isolate underground moisture from penetrating upward, preventing concentrated feeds such as corn and wheat bran, and hay from becoming damp and mildewed. This prevents feed spoilage, which leads to wasted farming costs and digestive tract diseases (such as enteritis) in livestock. Second, they can be used to cover and isolate silo pits. Geotextiles are placed over the surface of silage, then covered with plastic film. This not only enhances sealing, reducing the risk of silage spoilage due to contact with air, but also prevents the plastic film from being punctured by sharp parts of the silage due to its tensile strength. This also prevents direct contact between the plastic film and the feed, thereby protecting the nutritional quality of the silage.

4. Manure Handling and Sewage Discharge Areas

In manure storage areas, around septic tanks, and within sewage ditches on livestock farms, geotextiles offer the dual benefits of "leakage prevention and easy cleanup." Laying geotextiles at the bottom of manure dumps can prevent manure leachate from seeping into the subsoil and groundwater, preventing soil pollution and groundwater damage, and complying with environmentally friendly aquaculture wastewater discharge standards. Laying geotextiles along the inner walls of drainage ditches can reduce the adhesion of manure residues within the ditches, reducing the likelihood of clogging. It also prevents soil from being washed away by sewage, extending the life of the ditches and reducing the manpower and time required for desilting operations. It is particularly suitable for centralized sewage systems in large-scale farms.

5. Pasture Lawns and Grazing Areas

For livestock farms with large lawns, such as dairy farms and sheep pastures, laying geotextiles beneath the lawn root zone can create a layered structure of "lawn-geotextile-soil." On the one hand, geotextiles can block the contact between weed seeds and soil, inhibit weed growth, prevent weeds from competing with grass for nutrients, ensure grass yield and quality, and reduce the use of manual weeding or herbicides; on the other hand, during the grazing season, they can disperse the damage to lawn roots caused by livestock trampling, prevent lawn degradation and exposure, maintain pasture vegetation coverage, and at the same time reduce soil erosion caused by rainwater erosion, maintain the stability of the pasture ecological environment, and achieve sustainable grazing.

Geotextiles for livestock operations can be used in five major scenarios: pen floors, passage activity areas, feed storage and silage areas, manure treatment and sewage treatment areas, and pasture lawns, thanks to their core properties of durability, hydrophobicity, and barrier properties. They can not only optimize management by keeping the site dry, preventing soil compaction, and protecting feed quality, but also reduce livestock diseases, lower maintenance and environmental protection costs, and are suitable for various breeding models. They are important auxiliary materials for modern green animal husbandry.