Reinforced Machine Woven Fabric

1.It has good creep resistance and is not prone to relaxation under long - term load, making it suitable as a permanent reinforcement material.

2.It has high tensile strength (up to 20 - 100kN/m) and low elongation at break (≤25%), which can effectively restrain soil deformation and enhance structural bearing capacity.

3.The grid structure has a large frictional force with the soil, can evenly disperse the load, and enhance the stability of roadbeds, slopes, etc. (such as preventing roadbed settlement and slope landslides).

4.Wear-resistant and tear-resistant, suitable for coarse-grained soil or gravel environments (such as mines, water conservancy projects); has strong chemical stability and is resistant to corrosion by acids, alkalis, and salts.

5.Compared with traditional reinforcing materials (such as steel mesh), the cost is reduced by 30% - 50%, and the durability is similar (with a normal operating life of 15 - 20 years).

Product Introduction:

Reinforced Machine Woven Fabric is a geosynthetic material made from high-strength fibers through a weaving process. Due to its excellent reinforcement performance and structural stability, it is widely used in civil engineering.

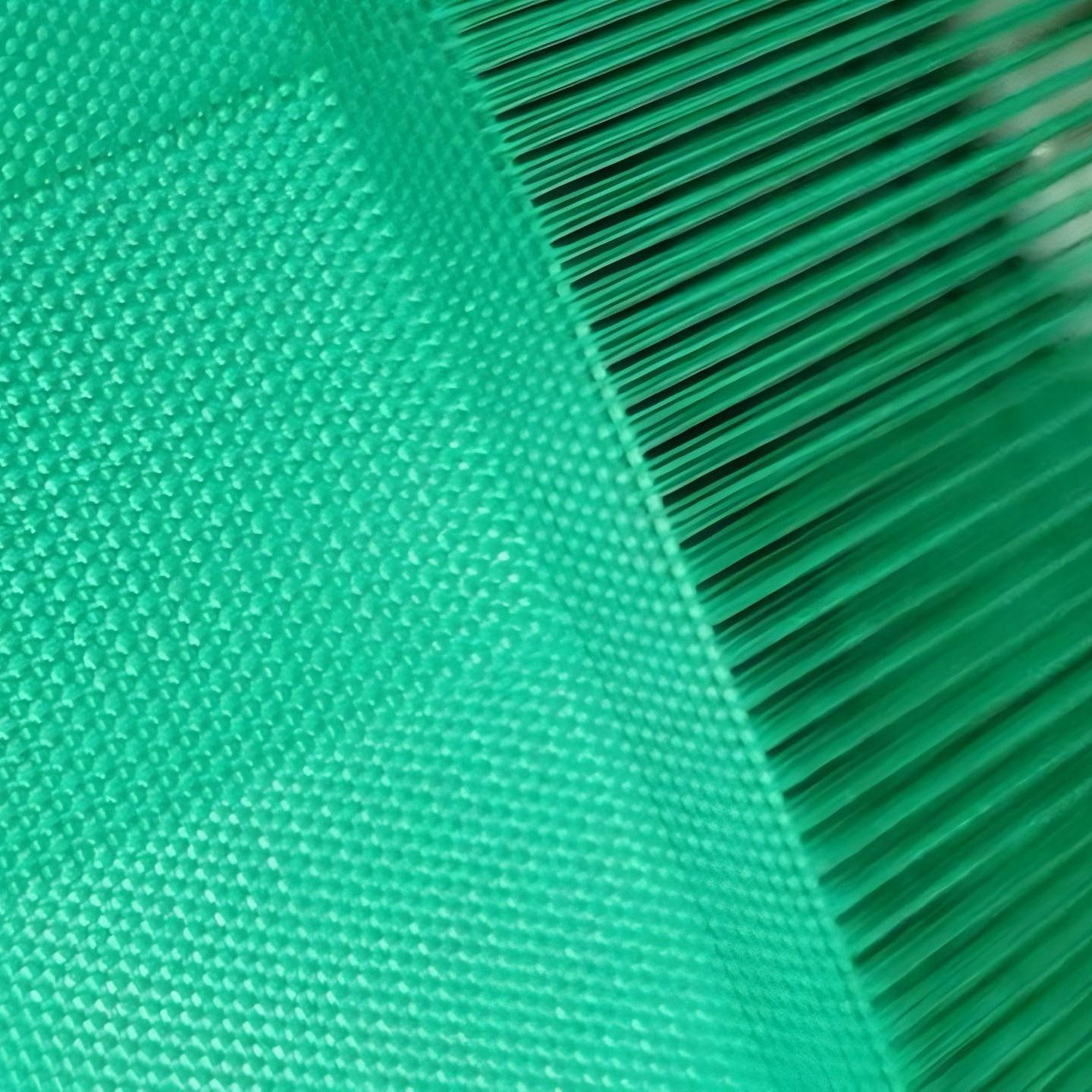

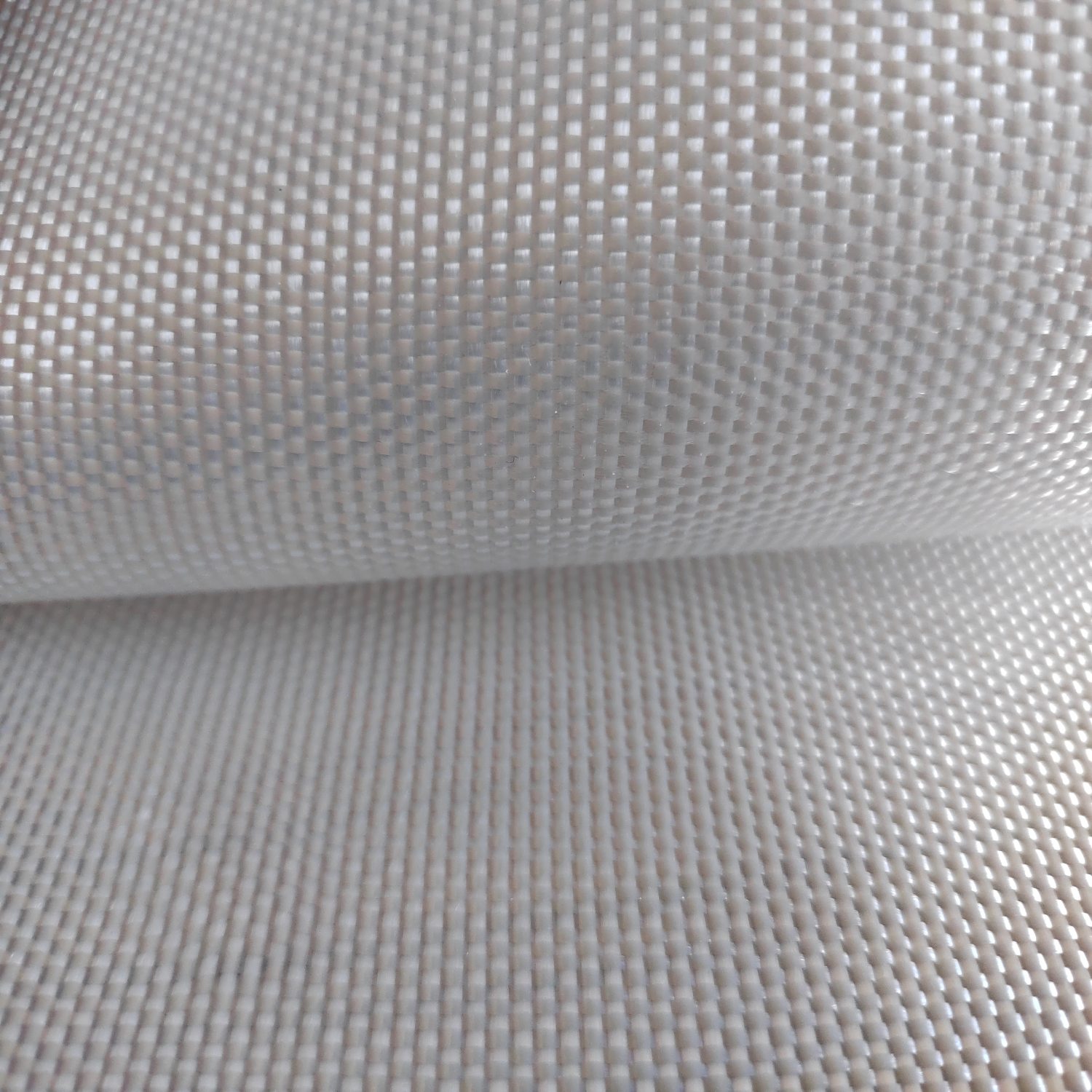

1.Core Material and Structure

Raw Materials:

Mainly use high - molecular polymer fibers such as polypropylene (PP) and polyester (PET), or glass fibers (coated with modified resin on the surface), which have the characteristics of high strength and low elongation.

Polypropylene material is resistant to chemical corrosion and is suitable for acidic or saline - alkaline environments; polyester material has stronger anti - ultraviolet aging ability; glass fiber has the highest tensile strength (up to over 1000kN/m).

Structure:

The warp and weft fibers are interwoven in a grid pattern to form regular rectangular or square apertures. The aperture size (ranging from 5mm×5mm to 100mm×100mm) and fiber density can be customized according to engineering requirements

The surface is usually coated (such as with PVC, styrene-butadiene rubber) to enhance wear resistance, UV resistance and friction with the soil.

2.Key performance advantages

Outstanding mechanical properties

High tensile strength: The polyester woven fabric can reach 50 - 150 kN/m, and the glass fiber woven fabric can reach 200 - 800 kN/m, far exceeding non - woven geotextiles.

Low elongation rate: The elongation at break is usually ≤ 10% (≤ 3% for glass fiber), which can effectively limit soil deformation and maintain structural stability.

Reinforcement and Isolation Functions

Reinforcement Mechanism: After the grid structure is embedded in the soil, the load is dispersed through frictional resistance and bite force, enhancing the shear strength of the soil (for example, the bearing capacity of the subgrade can be increased by 40%-70%).

Isolation Function: It separates soil layers of different properties (such as the crushed stone base layer and the soft soil subgrade), preventing mixing and resulting in strength attenuation.

Strong environmental adaptability

Resistant to chemical corrosion (resistant to acids, alkalis, and salt solutions), suitable for complex environments such as industrial waste yards and landfills; resistant to microbial erosion, with an underground service life of over 20 years.

Resistant to high and low temperatures: The polyester material can work stably in the range of -40°C to 120°C, and the glass fiber material has better high-temperature resistance (resistant to over 200°C).

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

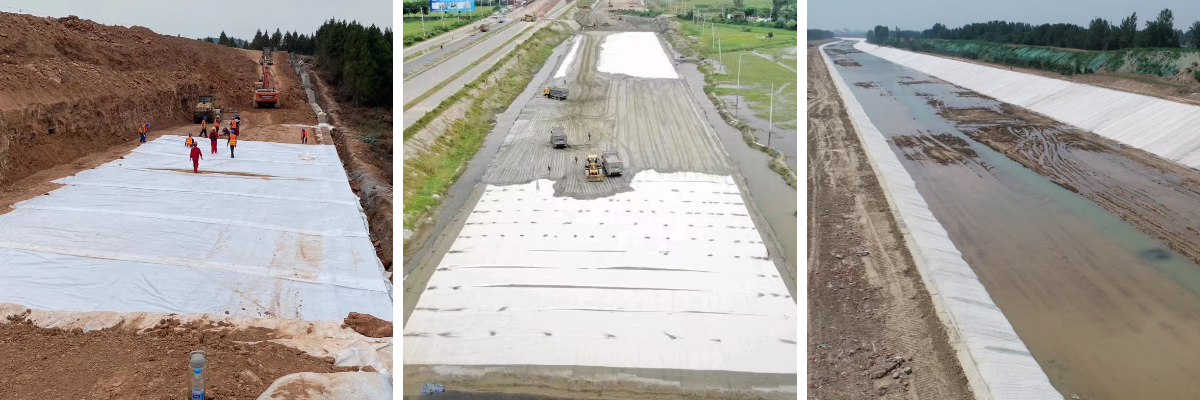

Traffic Engineering

Road ConstructionSubgrade Reinforcement: Laid between the subgrade and the base course, it disperses vehicle loads, reduces subgrade settlement and rutting (for example, in soft soil subgrade sections, it can increase bearing capacity by more than 40%).

Reconstruction of Existing Roads: Reinforcement treatment can inhibit the expansion of reflective cracks and extend the pavement renovation cycle.

Railway EngineeringBallast Bed Reinforcement: Prevents ballast from sinking, maintains track smoothness, and reduces maintenance costs (especially suitable for heavy - haul railways).

Hydraulic and Geotechnical Engineering

Dams and RiversDam Reinforcement: Enhance the anti - sliding stability of the dam body, reduce the settlement of the dam foundation, especially suitable for the isolation and reinforcement between the impervious core and the dam shell of earth - rock dams.

River Bank Protection: Laid on the surface of the slope to resist the scouring of water flow, and combined with vegetation planting to form ecological protection (such as the combination of ecological concrete and reinforced woven fabric).

Retaining Walls and SlopesReinforced Earth Retaining Wall: As a tensile reinforcement material, it forms a composite body with the backfill soil, reducing the earth pressure behind the wall and improving the anti - overturning ability (the height of the wall can reach 8 - 10 meters).

Mines and Environmental Protection Projects

Mining FieldMine Road Reinforcement: Withstand the rolling of heavy-duty trucks, reduce road surface damage, and extend the service life of the road (such as open-pit mine transportation roads).

Tailings Dam Reinforcement: Reinforcement treatment improves the stability of the dam body and prevents the landslide of tailings deposits.

Environmental Protection ProjectsLandfill Sites: Used for the reinforcement of the landfill reservoir slope to prevent the landslide of the garbage pile; or as a reinforcing material for the cover layer to enhance the stability of the anti-seepage system.

Special Engineering and Scenarios

Desert and Permafrost RegionsIn desert road construction, reinforcement is used to resist wind and sand erosion and foundation fluidity, enhancing subgrade stability;In permafrost areas, subgrade reinforcement is carried out to reduce frost heave and thaw settlement deformation caused by temperature changes.

Slope Greening and Ecological EngineeringAs the reinforcement framework of vegetated concrete, it fixes the greening matrix and promotes the growth of slope vegetation (such as ecological slopes of expressways).

Emergency RescueTemporarily reinforce dikes during floods, or quickly lay reinforced fabric to stabilize soil during emergency landslide treatment.

Reinforced woven fabric, with the characteristics of "high strength, low deformation, and long service life", has become the core material for solving problems such as soil settlement, slope instability, and insufficient foundation bearing capacity. It has significant advantages, especially in projects that need to withstand long - term heavy loads or complex loads.