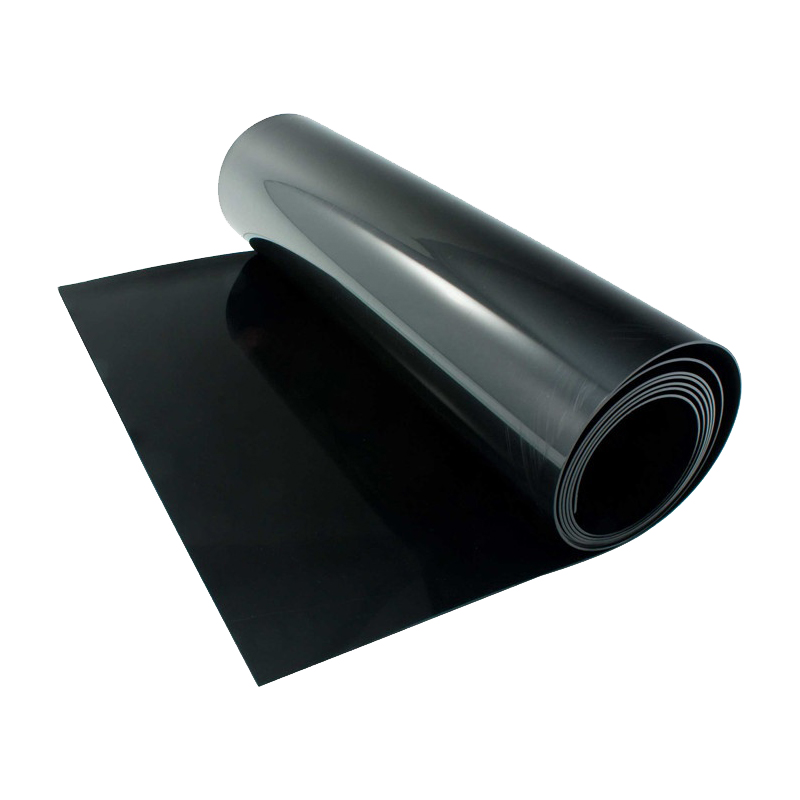

HDPE Liner

• It has excellent anti-seepage performance, a very low coefficient of permeability, and a remarkable effect in blocking liquid leakage.

• It has outstanding mechanical properties, high tensile strength, good toughness, puncture resistance, deformation resistance, and can adapt to foundation settlement.

• It has strong environmental adaptability, can resist high and low temperatures, and is resistant to ultraviolet aging.

• It has a long lifespan, low construction cost, outstanding cost-effectiveness in large-scale projects, and can be recycled and reused.

• The material is non-toxic and harmless, does not pollute water and soil, can be recycled after being discarded, and meets environmental protection requirements.

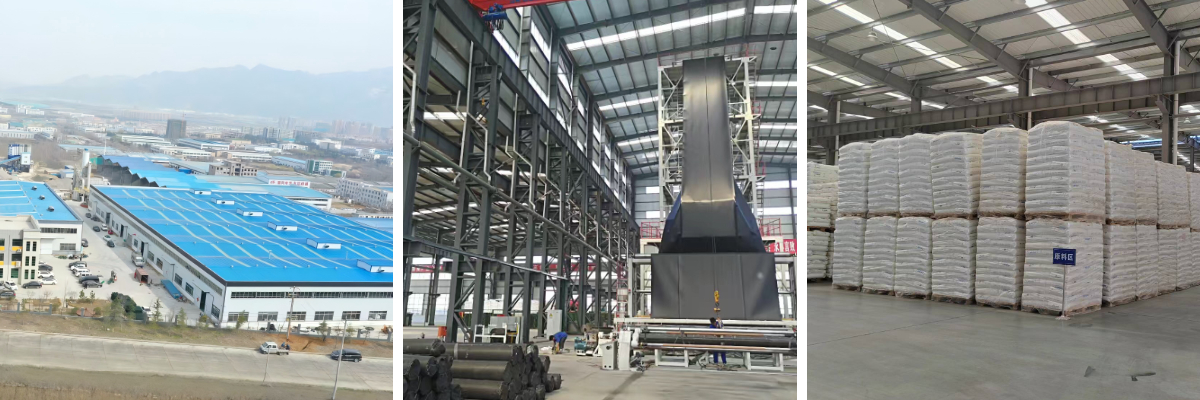

Product Introduction:

HDPE Liner is a waterproof and barrier material made from HDPE. It is widely used in engineering fields such as water conservancy, environmental protection, and transportation. Its advantages are mainly reflected in multiple aspects such as material properties, construction adaptability, durability, and comprehensive cost.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

I. Water Conservancy Projects

Seepage prevention for reservoirs and dams: Laid at the bottom of the reservoir and on the water-facing side of the dam, it blocks water seepage, improves the stability of the dam body, and reduces water resource losses.

Channels and Irrigation Systems: Used for the anti-seepage of irrigation channels and drainage ditches to prevent water from seeping downward or soil erosion, and improve water conveyance efficiency (such as the anti-seepage of channels in the South-to-North Water Diversion Project).

Reservoirs and Artificial Lakes: Construct enclosed water storage spaces to prevent water from seeping into the ground and soil pollutants from infiltrating into the water body, thus ensuring water quality.

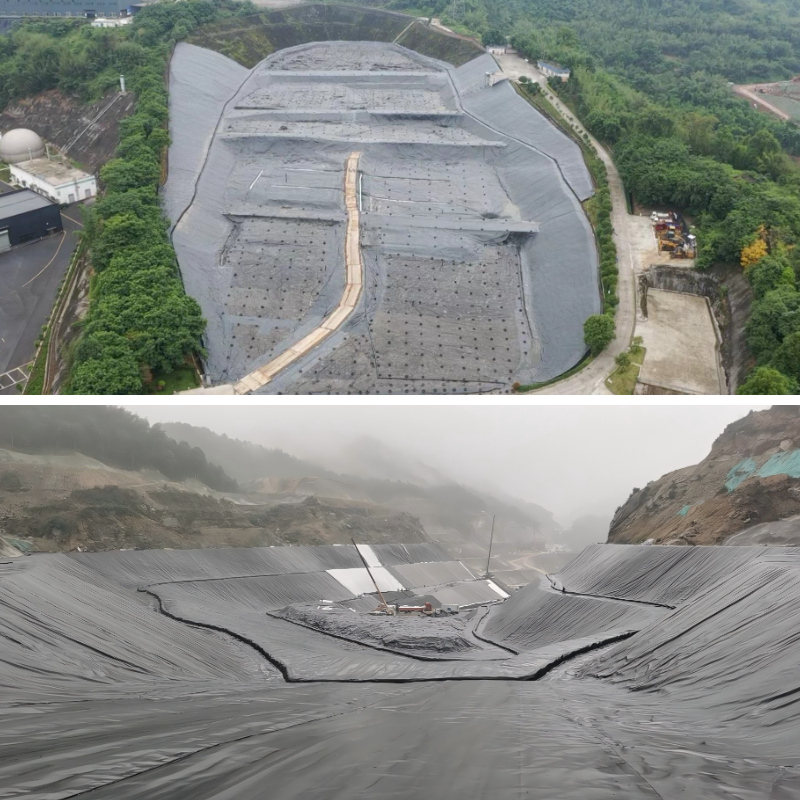

II. Environmental Protection Projects

Landfill: As the anti-seepage layer at the bottom and slopes of the landfill, it blocks the seepage of leachate from polluting the groundwater, and at the same time prevents external rainwater from infiltrating and increasing the amount of leachate (often used in combination with GCL bentonite mats).

Sewage treatment plant: It is used for the anti-seepage of tanks such as regulating tanks, aeration tanks, and sedimentation tanks to prevent sewage leakage from polluting the soil, and at the same time resist the corrosion of chemical media.

Industrial Waste Residue Yard: Isolate industrial waste such as heavy metals and toxic waste liquids, prevent pollutants from seeping into the surrounding environment, and meet environmental protection emission standards.

III. Traffic Engineering

Highway and railway subgrades: Laid beneath the subgrade, it blocks the subgrade softening caused by the rise of groundwater, prevents rainwater on the road surface from seeping downward and damaging the subgrade structure, and improves the durability of the road.

Tunnel and Culvert Seepage Prevention: It is used for seepage prevention on the top and side walls of tunnels, reducing the risk of structural corrosion or road surface slipperiness caused by groundwater seepage (such as subway tunnels and mountain culverts).

Airport runway foundation: Control the moisture migration of the foundation, prevent the runway from deforming due to frost heave or settlement, and ensure flight safety.

IV. Energy Engineering

Anti-seepage for Petrochemical Industry: Laid in oil fields, refineries, and oil storage tank areas to prevent the leakage of oil and chemical solvents from polluting the soil and groundwater, meeting the requirements of environmental protection regulations.

Anti-seepage for Nuclear Power Plants: Used for anti-seepage of nuclear waste storage pools and radioactive wastewater treatment pools to ensure high-security isolation and prevent the diffusion of radioactive substances.

Biogas Digester and Landfill Gas Collection: It serves as the anti-seepage layer at the bottom of the biogas digester, seals the gas to prevent leakage, and improves the efficiency of biogas collection.

V. Agriculture and Ecological Engineering

Aquaculture: Lining the bottom of fish ponds and shrimp ponds to prevent seepage, maintain stable water levels, reduce the frequency of water changes, and prevent the surrounding soil from being polluted by aquaculture wastewater (such as the construction of high - density fish ponds).

Ecological Wetlands: Construct an anti-seepage layer for artificial wetlands, control the water level to create a suitable growth environment for animals and plants, and at the same time prevent sewage seepage from damaging the ecosystem.

Yantian and Brine Storage Ponds: Used for seepage prevention in salt pans' solar evaporation ponds, preventing brine leakage and improving salt production efficiency and output.

VI. Mining Engineering

Seepage prevention of tailings pond: Cover the bottom and slopes of the tailings pond to block the seepage of tailings wastewater (containing heavy metals) and protect the ecological environment around the mining area.

Anti-seepage for Mine Pit Backfilling: Laid during the backfilling of abandoned mine pits to prevent the infiltration of sewage generated by rainwater scouring of mine slag, and reduce the risk of soil and groundwater pollution.