Silknet Geocell

1.Strong Structure

The honeycomb-shaped 3D grid provides high-strength lateral constraint, enhances foundation bearing capacity, and distributes loads to resist deformation.

2.Durable & Weather-Resistant

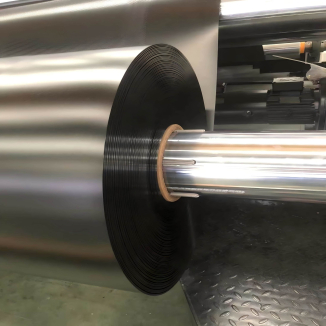

Made of HDPE/PP, it resists aging and acid-base corrosion, adapts to -50℃~+80℃ environments, and has a service life of over 50 years.

3.Easy Construction

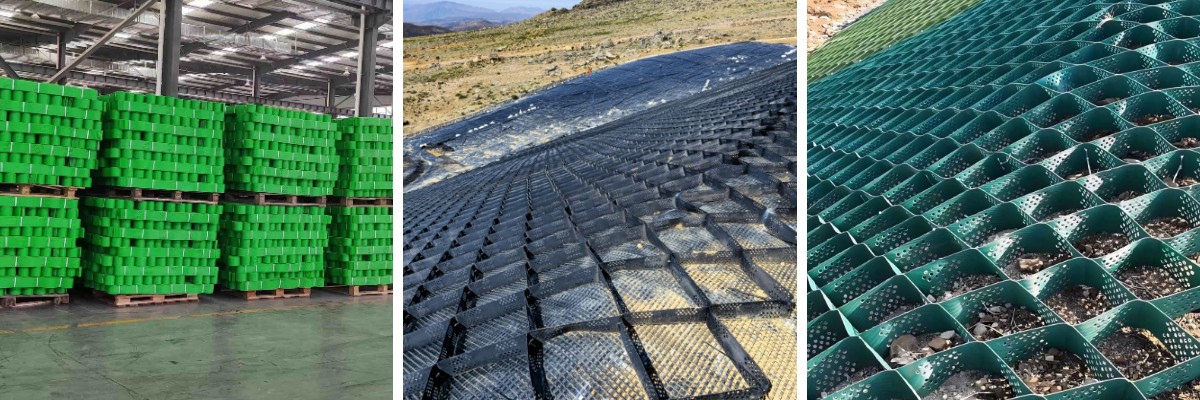

Foldable for transportation, it can be deployed and filled on-site, adapting to complex terrains with high construction efficiency.

4.Multiple Functions

Applied in foundation reinforcement, slope protection, ecological greening, etc., combining engineering protection with ecological benefits.

Product Introduction:

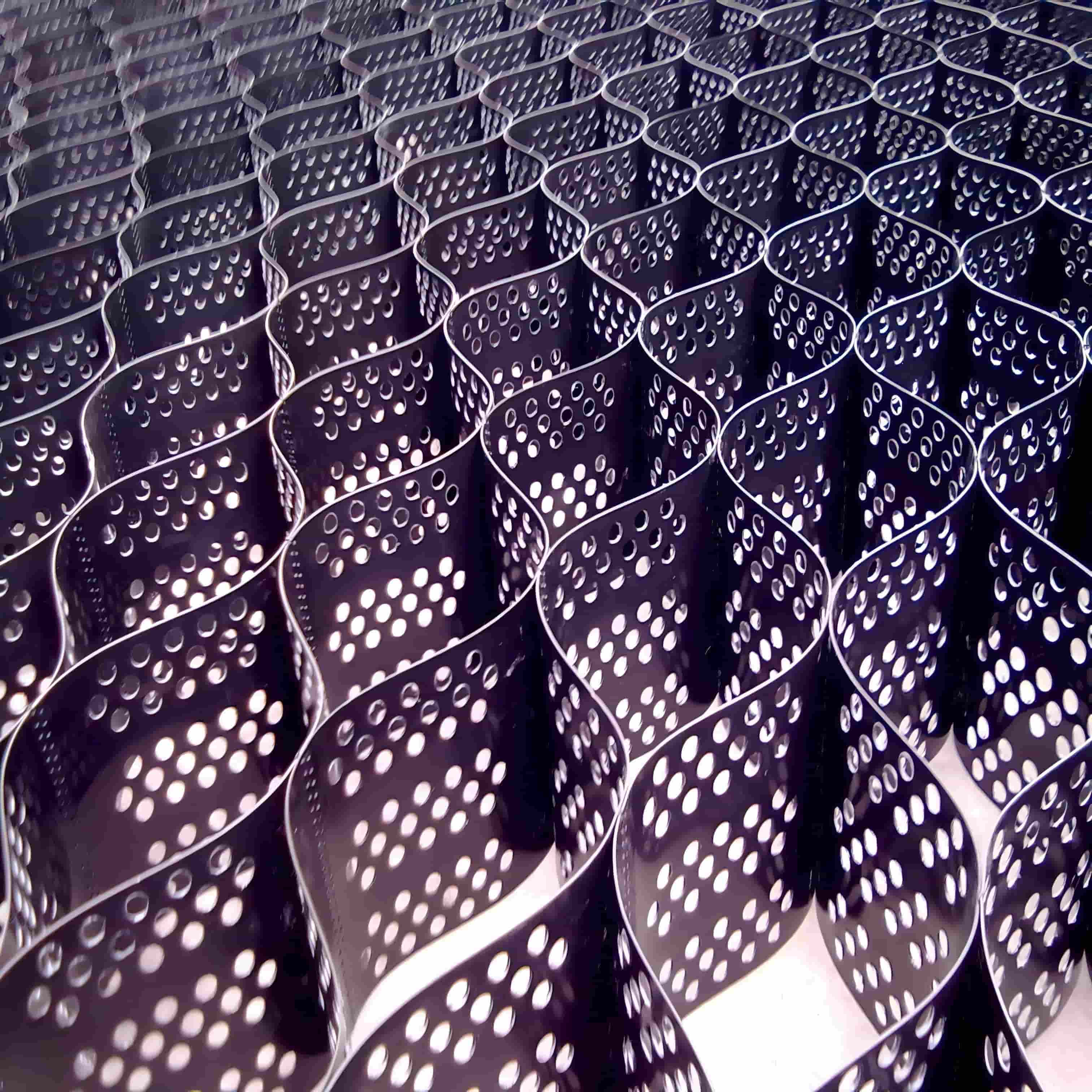

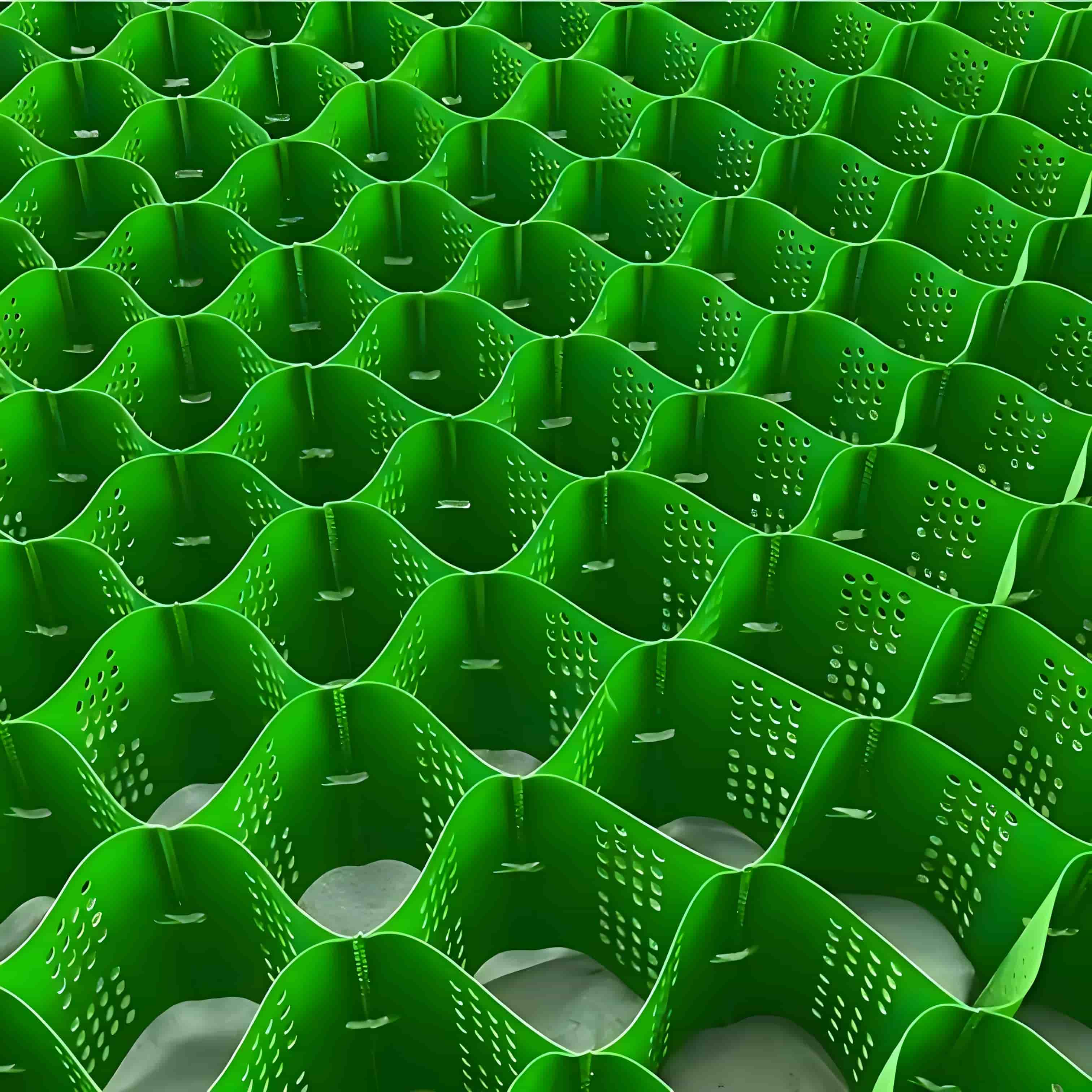

Silknet Geocell is a honeycomb-shaped three-dimensional grid structure formed by ultrasonic welding, high-frequency welding or riveting of high-strength polyethylene (HDPE) or polypropylene (PP) sheets. When unfolded, it presents a three-dimensional honeycomb shape and can be filled with materials such as earth and stone, concrete or vegetation to form a composite structure with high rigidity and lateral constraint capability.

Characteristics

1.Three-Dimensional Structure

When expanded, geocells form a three-dimensional network structure that provides lateral restraint to limit the displacement of filled materials, enhancing the overall integrity of the soil. This structure effectively distributes loads and reduces differential settlement.

2.High Strength and Durability

Manufactured from high-strength polymeric materials (e.g., HDPE, PP), geocells exhibit excellent tensile and compressive strength, as well as resistance to aging. They can withstand long-term loads and harsh environmental conditions, making them suitable for various challenging applications.

3.Lightweight and Easy to Install

Geocells are lightweight, facilitating convenient transportation and installation. Once deployed, they can be directly filled with materials, enabling high construction efficiency, especially in projects with complex terrain or limited workspace.

4.High Adaptability

The height, dimensions, and shape of geocells can be customized to meet specific engineering requirements, accommodating diverse geological conditions and load demands. They are widely applicable in scenarios such as soft soil foundation treatment, slope stabilization, and abutment backfilling.

5.Environmentally Friendly and Cost-Effective

The materials used in geocells are recyclable, minimizing environmental impact. By reducing earth excavation and material consumption, they lower construction costs while shortening project durations.

6.Drainage and Permeability

Geocell sheets can be designed as permeable structures to facilitate drainage, thereby mitigating water pressure effects on the soil and enhancing the long-term stability of the project.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Used for stabilizing railway subgrades.

2.Used for stabilizing soft subgrade in highway engineering.

3.Used for load-bearing embankments and retaining walls.

4.Applied for shallow watercourse regulation.

5.Used for pipeline and sewer support systems.

6.Utilized for landslide prevention and hybrid retaining walls under load-bearing conditions.

7.Designed for standalone retaining walls, quay walls, flood embankments, and related structures.

8.When encountering soft subgrade in highway construction, geocell technology significantly reduces labor intensity, decreases required roadbed thickness, accelerates construction progress, enhances performance, and substantially lowers project costs.