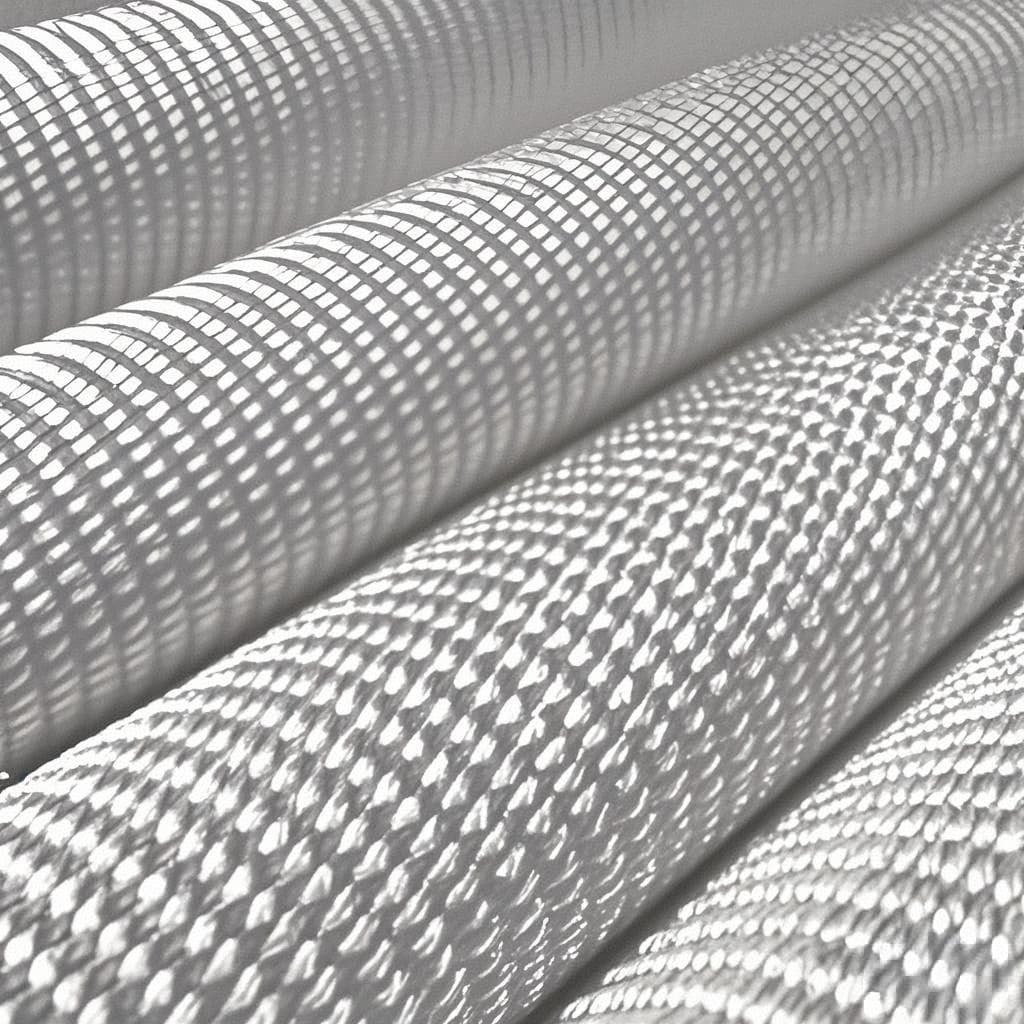

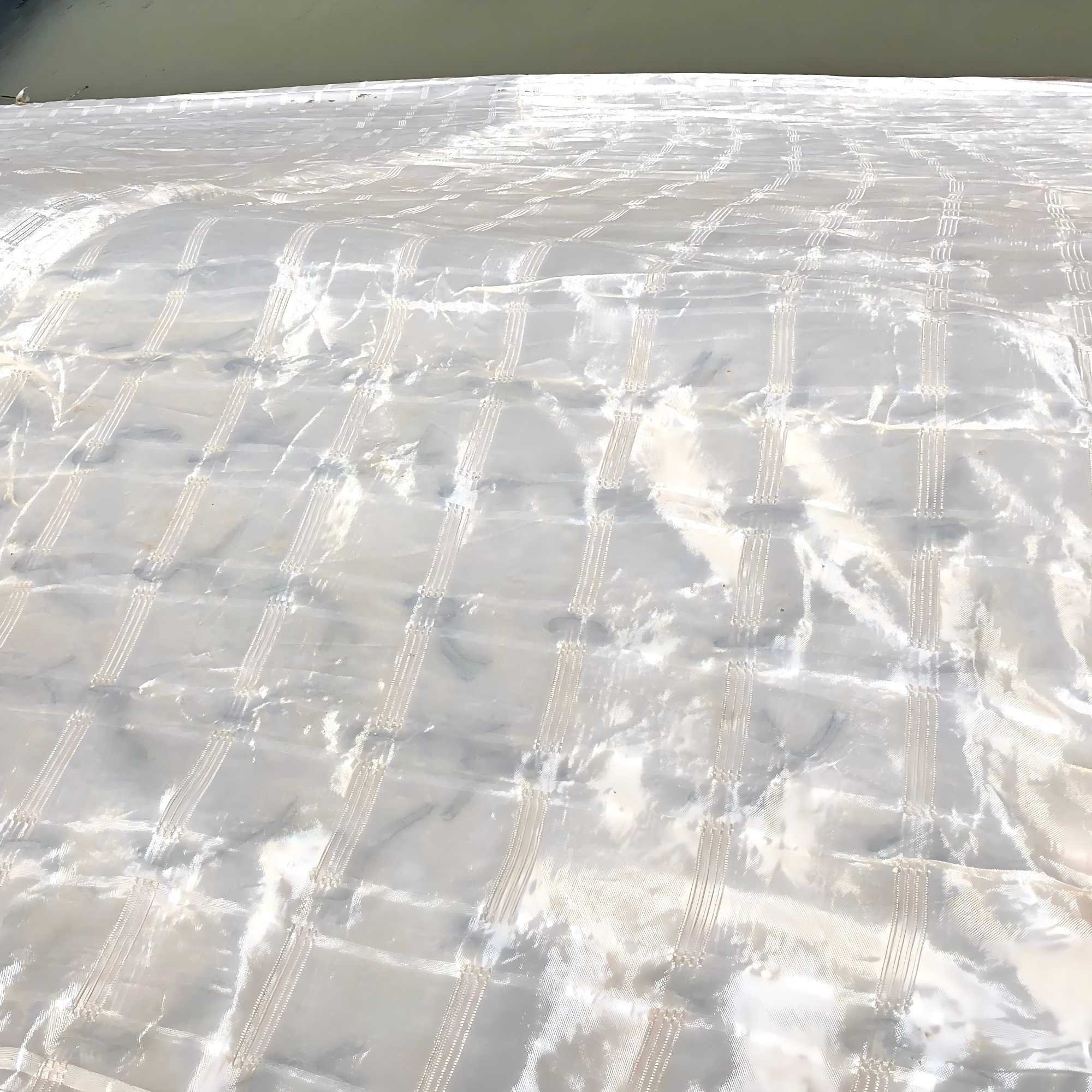

Polypropylene Woven Geotextile

It has strong tensile and tear resistance and can bear a large load.

It has good durability and a long service life.

It has excellent water permeability, a stable fabric structure, and both filtering and drainage functions.

It is convenient for construction. With regular dimensions and light weight, it is easy to cut, transport and lay.

It has a wide range of applications and is suitable for various engineering scenarios such as subgrade reinforcement, dam protection, and river regulation, adapting to different terrains and working conditions.

Product Introduction:

Polypropylene Woven Geotextile is a geosynthetic material made from polypropylene (PP) filaments through a weaving process. It is widely used in engineering fields such as water conservancy, transportation, and environmental protection.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

I. Hydraulic Engineering

Dike and River Channel Treatment: Used for reinforcing the slopes of dikes and the filter layer of the dike foundation to prevent seepage failure of soil; in river channel regulation, it serves as a slope protection cushion to resist the scouring of water flow. Reservoir and Channel Seepage Prevention: Combined with geomembrane to form a "two - layer fabric and one - layer membrane" structure, used for the seepage prevention layer of reservoir dams and irrigation channels, and provides reinforcement support at the same time. Flood Control and Emergency Rescue: Reinforcement and water filtration of temporary cofferdams and flood - control dikes, quickly blocking sediment and draining water.

II. Traffic Engineering

Highway and Railway Subgrades: Laid between the subgrade and the foundation to enhance subgrade bearing capacity, disperse loads, and reduce settlement (such as soft soil foundation treatment). Slopes and Retaining Walls: Used as reinforcement materials in slope protection to prevent landslides; the filter layer on the back of the retaining wall drains water and prevents soil loss at the same time. Airport and Port Engineering: Reinforce the foundation of airport runways, and use for filtration and reinforcement of the revetments of port terminals to resist ship loads and wave impacts.

III. Environmental Protection Projects

Landfill: It serves as the protective layer of the anti-seepage system at the bottom of the landfill, preventing the geomembrane from being punctured by sharp objects and assisting in drainage at the same time. Sewage Treatment Project: It is used for the reinforcement and filtration of the base of sewage treatment tanks and oxidation ponds. Its chemical corrosion resistance is suitable for the sewage environment. Mine and Ecological Restoration: It is the filter layer of the mine tailings dam, fixes the vegetation soil in the ecological slope greening, and prevents soil erosion.

IV. Municipal and Construction Engineering

Underground Engineering: Ground reinforcement for subway tunnels and underground utility tunnels to reduce soil deformation during construction. Landscaping: Drainage layer for flower beds and golf courses, soil reinforcement for park walkway foundations to maintain terrain stability. Filling Engineering: Reinforcement material for backfilling building foundations, improving the integrity and bearing capacity of filled soil.

V. Energy Engineering

Oil and Gas Pipelines: Reinforce the foundation during pipeline laying to prevent pipeline damage caused by soil settlement. Nuclear Power Plants and Hydropower Generation: Foundation treatment for nuclear power plant sites, and the filter and anti-seepage systems for hydropower station dams.

VI. Special Engineering Scenarios

Military Engineering: Rapid reinforcement of temporary fortifications and military roads to meet emergency construction requirements. Desert and Permafrost Areas: Windbreak, sand fixation, and reinforcement of desert highway foundations, and anti-freezing and swelling reinforcement treatment of projects in permafrost areas.

Company advantages:

Shandong Chuangwei New Material Co., Ltd. owns more than 20 modern production lines for environmental - protection engineering materials. Its products include polyethylene geomembranes, non - woven/fabric composite geomembranes, synthetic filament spunbond and needle - punched non - woven geotextiles, synthetic staple fiber needle - punched non - woven geotextiles, three - dimensional composite drainage nets, sodium bentonite geosynthetic clay liners, 10 - meter - wide rough - surfaced geomembranes, and nearly a hundred other products.