Geocell Slope

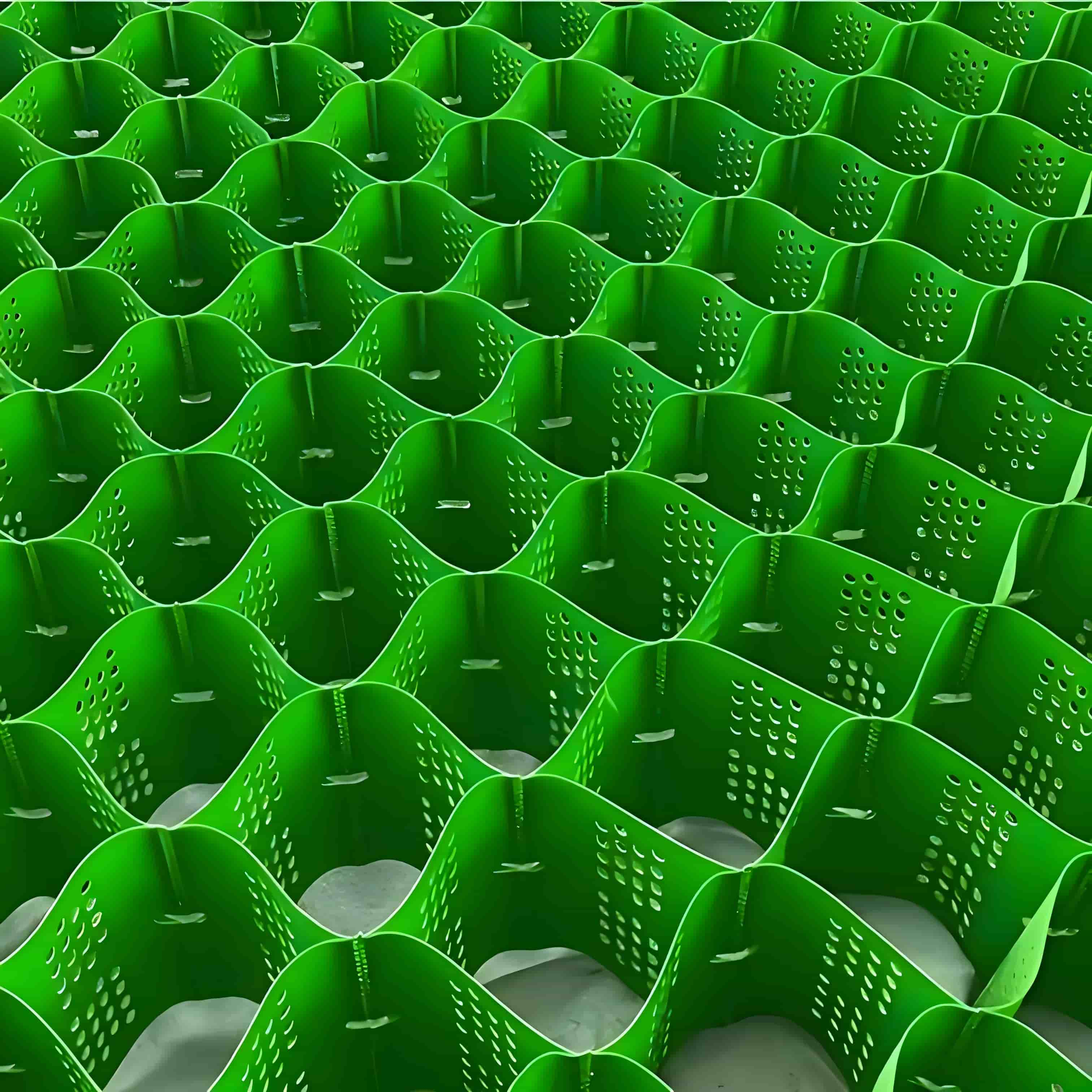

1.High structural strength and good stability: The unique honeycomb shaped three-dimensional structure enables the material to evenly distribute the load under stress, enhance the overall deformation resistance, and effectively improve the stability of the foundation or slope.

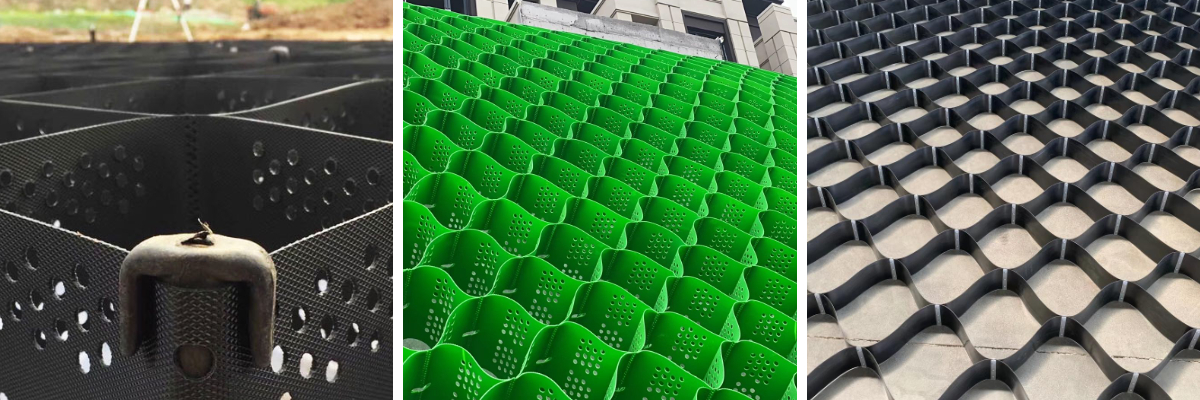

2.Convenient and efficient construction: After unfolding, it can be directly laid like a honeycomb without complex processing, which can greatly shorten construction time and reduce labor intensity, especially suitable for construction in complex terrain areas.

3.Strong adaptability: It can adapt to different geological conditions and climatic environments, and can play a good reinforcement effect on special sites such as soft soil foundations, desert areas, and steep slopes.

4.Ecological and environmental protection: Open structures are conducive to vegetation growth and can be combined with ecological greening. In slope protection and other engineering projects, they can not only stabilize the soil but also beautify the environment, achieving coordination between engineering and ecology.

Products Introduction:

Geocell Slope is a three-dimensional mesh structure formed by strong welding or riveting of high-strength HDPE (high-density polyethylene) or PP (polypropylene) copolymer broadband. Due to the practical needs of the project, some of the membranes in the geocell will be perforated. When not in use, it can be folded up for easy transportation; During construction, opening and filling it with loose materials such as soil, rock, or concrete can form a structure with strong lateral confinement and high stiffness.

Product Features:

1.High strength and stability: Made of high-strength polymer materials, it has excellent tensile strength and durability. Its unique honeycomb shaped three-dimensional structure can evenly distribute the load under stress, effectively suppress the lateral displacement of soil particles, and greatly enhance the overall deformation resistance. For example, in road subgrade reinforcement, the bearing capacity of the subgrade can be significantly improved, the settlement and deformation of the pavement can be reduced, and the service life of the road can be extended.

2.Good drainage performance: The three-dimensional structure creates gaps between the compartments, effectively removing moisture from the soil, reducing the adverse effects of water on the foundation, and preventing problems such as foundation softening and decreased bearing capacity caused by accumulated water. Its advantages are particularly evident in rainy areas or areas with high groundwater levels.

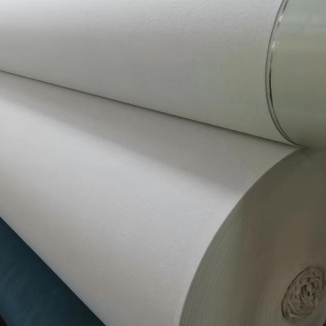

3.Lightweight material: The geocell material is lightweight, reducing transportation costs and labor intensity during construction. At the same time, its characteristics of wear resistance, chemical stability, resistance to light and oxygen aging, acid and alkali resistance make it suitable for various complex soil conditions such as different soils and deserts, as well as harsh climatic environments.

4.Convenient and efficient construction: flexible expansion and contraction, small space occupation during transportation, easy connection upon arrival at the construction site, and can be quickly stretched into a mesh. The construction process is relatively simple and can significantly shorten the construction time, making it particularly suitable for carrying out operations in areas with complex terrain and limited construction conditions.

5.High flexibility: The geometric dimensions of the geogrid, such as height and welding distance, can be flexibly changed according to different engineering requirements to customize products that meet specific engineering requirements and adapt to diverse engineering scenarios.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Roadbed reinforcement: Under adverse foundation conditions such as soft soil foundation and collapsible loess, geogrids can effectively improve the bearing capacity of the foundation, reduce the settlement and uneven settlement of the roadbed. In some highway constructions, by laying geogrids and filling them with suitable materials, the stability of the roadbed is enhanced, ensuring the long-term performance of the road.

2.Slope protection: When used for road slope protection, geocells can prevent the sliding and erosion of slope soil. After fixing it on the slope and filling it with soil, vegetation can also be planted, utilizing the soil stabilization effect of plant roots to further enhance the stability of the slope, while also achieving the effect of greening and beautifying the environment.

3.Railway engineering: Stabilize the railway subgrade, enhance the strength and stability of the subgrade to withstand the huge loads and vibrations generated during train operation. When constructing railway fill subgrade in permafrost regions, the unique vertical reinforcement effect and overall lateral confinement of geogrids can ensure the minimum filling height is reached and prevent frost damage to the subgrade.

4.Embankment construction: bear the load of the embankment, improve the stability of the embankment, and prevent deformation and landslides of the embankment body. Meanwhile, its excellent drainage performance helps to reduce the pore water pressure inside the embankment and enhance its anti-seepage ability.

5.River management: In shallow water river management, geogrids can be used for riverbank protection, resisting the erosion of water flow and protecting the stability of riverbanks. By filling with materials such as stone, it can also serve as a bottom protection, maintaining the normal shape and flow conditions of the river channel.

6.Desert control: In windy and sandy areas, geogrids play a lateral limiting role in loose sand particles, which can fix sand dunes and prevent wind erosion. After filling with sandy soil, favorable conditions are created for vegetation growth, which helps to restore desert vegetation and improve the ecological environment.

7.Beach restoration: When used in beach restoration projects, geogrids can enhance the stability of the beach, resist the erosion of waves, and protect the coastline. Meanwhile, its structure is conducive to the habitat and reproduction of marine organisms, promoting the restoration of beach ecosystems.

8.Supporting structure: can be used to construct supporting structures, such as load-bearing gravity hybrid retaining walls used to prevent landslides. By working together with the filling material, it provides strong lateral support, stabilizes the soil, and prevents geological disasters such as landslides.

Geocell Slope have demonstrated outstanding advantages in multiple engineering fields due to their unique structural design and excellent material properties. It not only significantly improves the stability and bearing capacity of engineering structures, but also has the characteristics of convenient construction, economic and environmental protection. With the continuous development of engineering technology and in-depth research on geogrids, their application scope will further expand, providing more reliable and efficient solutions for various infrastructure construction and ecological environment governance.