Geocell Foundation

1.Enhance foundation bearing capacity, reduce lateral displacement of materials through three-dimensional constraints, and improve foundation stability;

2.Strengthen the shear resistance and anti-sliding performance of soil, effectively prevent soil erosion;

3.Reduce the amount of filling materials, lower transportation and construction costs;

4.Convenient for construction, can be quickly unfolded and spliced, adapt to complex terrain, and shorten the construction period;

5.Made of corrosion-resistant and anti-aging materials, with a long service life (20-50 years).

Product Introduction

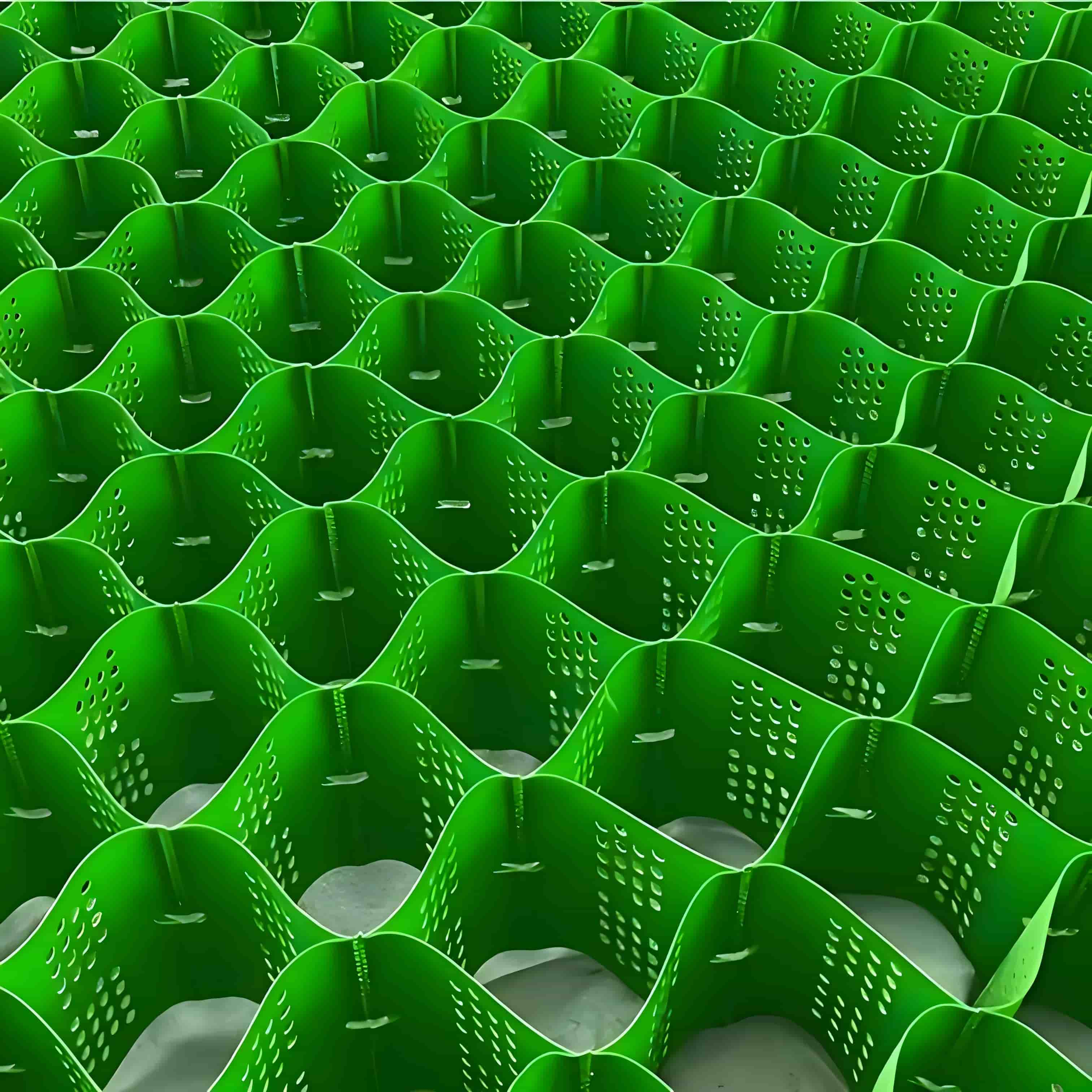

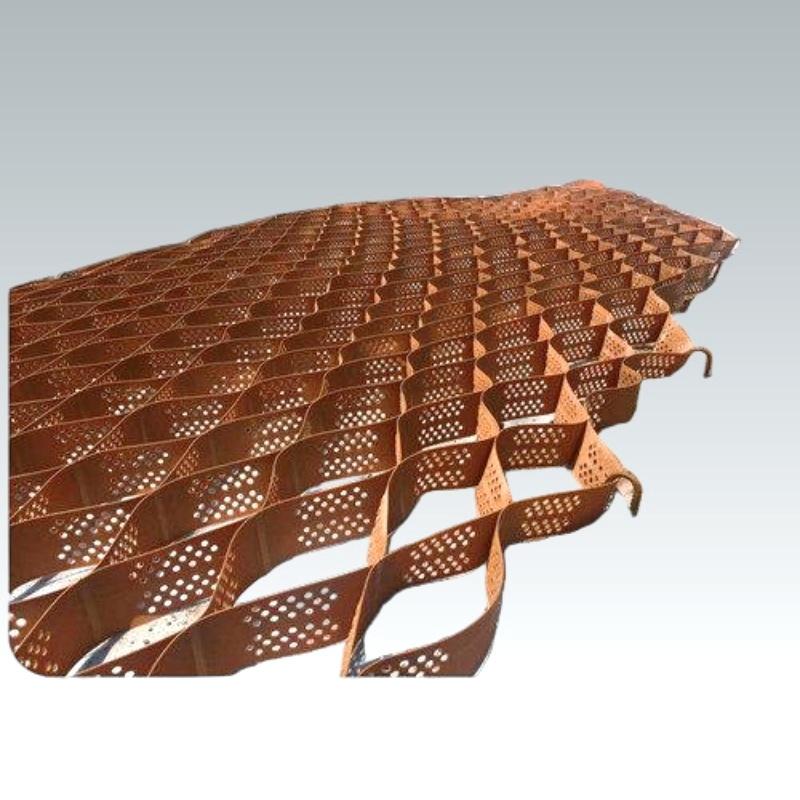

Geocell Foundation is a three-dimensional honeycomb structure geosynthetic material made of high-strength polymer materials, often using materials such as high-density polyethylene (HDPE) and polypropylene (PP).

Product Features

1.Scalability and convenience: It can be folded during transportation, greatly reducing its volume and making it easy to handle; It can be quickly stretched into a mesh during construction, making it easy to operate. After filling with loose materials such as soil, gravel, and concrete, a structure with strong lateral confinement and high stiffness can be formed.

2.Excellent material performance: lightweight texture, reducing transportation and construction burden; Strong wear resistance, maintaining structural integrity under long-term useand friction environment; Chemical stability, resistance to light and oxygen aging, acid and alkali erosion, and adaptability to various complex soil conditions and harsh environments such as deserts and saline alkali land.

3.Enhance bearing and stability performance: It has high lateral confinement ability, effectively restrains filling materials, significantly improves the bearing capacity of the roadbed, evenly disperses loads, reduces settlement and deformation, and has good anti slip performance, enhancing the stability of the structure.

4.Customization of dimensions: The height, welding distance, aperture and other geometric dimensions of the geogrid can be flexibly adjusted according to different engineering requirements to meet diverse project requirements.

Product parameters

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Application

1. Road engineering

Roadbed reinforcement: Laying geogrids on soft soil foundations can disperse loads, reduce settlement, and enhance roadbed stability. It is commonly used for roadbed treatment of highways and railways.

Road surface repair: When renovating old roads or encountering problems such as cracks and subsidence, laying geogrids can improve the overall integrity of the road surface structure and extend its service life.

Slope stability: Geogrid cells are developed on the surface of the slope and filled with materials such as soil, sand, and gravel to form a reinforced cushion layer, which can prevent slope collapse and landslides, especially suitable for steep slopes or areas with poor geological conditions.

Vegetation restoration: Grasses, shrubs and other plants can be planted in the greenhouse to achieve ecological protection, balance slope stabilization and greening functions, and are commonly used in highway slopes, mine greening and other projects.

3. Water conservancy engineering

River regulation: Laying geogrids on the bank slopes of the river can resist water erosion, protect the bank slopes from erosion, and combine ecological bags and other materials to construct ecological revetments.

Dam reinforcement: used for anti-seepage and reinforcement treatment of dams, enhancing their anti sliding stability and reducing the risk of seepage deformation.

4. Airport and Port Engineering

Airport runway foundation: Laying geogrids in the runway base or sub base can improve the bearing capacity and deformation resistance of the foundation, and adapt to the heavy load requirements of aircraft takeoff and landing.

Port yard: used for yard foundation treatment, reducing foundation settlement, improving yard efficiency and safety.

5. Other fields

Desert control: Laying geogrids in desert areas can fix sand dunes, prevent sand flow, create conditions for vegetation growth, and help prevent desertification.

Landfill site: used for reinforcing the anti-seepage layer and protective layer of the landfill site, enhancing structural stability, and preventing leakage pollution.

Geogrid cells play an important role in reinforcing, protecting, and stabilizing civil engineering due to their advantages of lightweight, high strength, aging resistance, and convenient construction. They have broad application prospects, especially in ecological and environmentally friendly engineering requirements.