Cement Ditch Liners

1.Efficient and labor-saving construction:The texture is lightweight and can be cut, and it solidifies immediately after watering without the need for complex equipment. It is suitable for complex terrains, saving labor, time, and time.

2.Solid and durable performance:After solidification, it is resistant to pressure and seepage, acid and alkali erosion, reducing water leakage and collapse problems, and has a longer service life than traditional materials.

3.Wide scene adaptation:Flexible and adaptable to irregular structures, suitable for various scenarios such as agricultural irrigation, municipal drainage, and water conservancy engineering.

4.Combining economy and environmental protection:Less maintenance in the later stage, low long-term costs, less production energy consumption and dust pollution, in line with the needs of green construction

Product Introduction

1、 Basic attributes

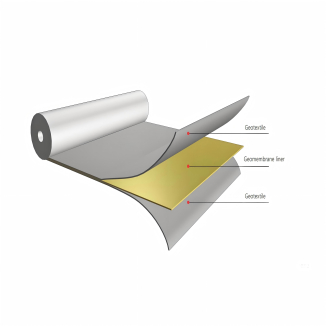

Material composition: Cement Ditch Liners is a three-dimensional fiber structure woven from polyethylene and polypropylene filaments as the skeleton, containing a special formula of dry concrete mixture, forming a composite structure of "fiber+cement".

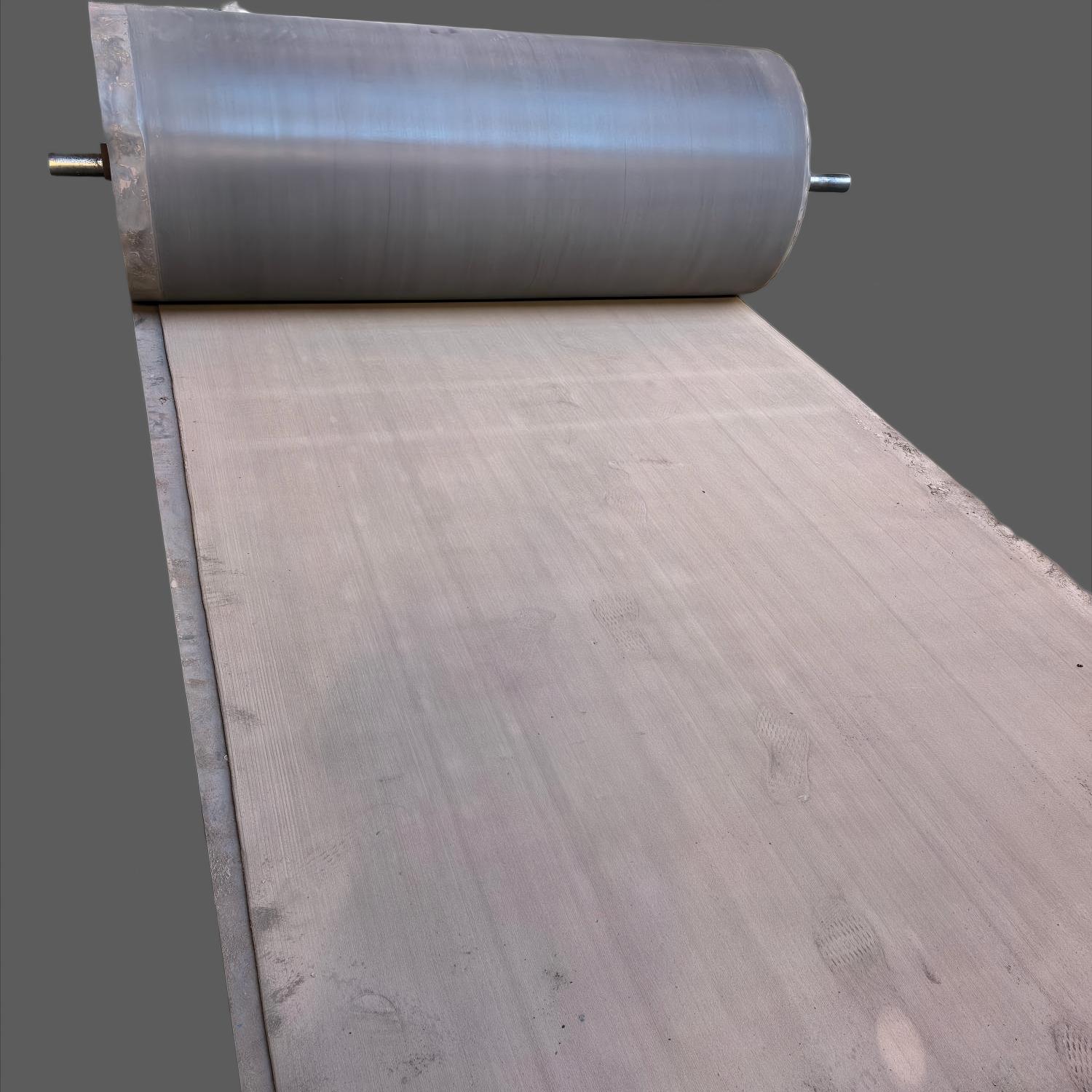

Morphological features: When not in contact with water, it appears as a soft blanket and can be curled for storage and transportation. It weighs approximately 15 kilograms per square meter; After encountering water, it quickly solidifies through hydration reaction, forming a thin and hard concrete layer with structural stability.

Specification features: Common thickness of 5-30mm, can be cut to any size according to engineering requirements, suitable for different shapes of ditch structures, with low requirements for the flatness of the base layer.

2、 Core functions

Waterproof and anti-seepage: The solidified dense concrete layer itself has good barrier properties, which can effectively reduce water infiltration and reduce water leakage problems in ditches, especially suitable for scenarios such as irrigation canals and sewage canals that require water retention or pollution prevention.

Structural protection: After solidification, the compressive strength reaches over 30MPa, with strong resistance to wear and erosion. It can protect the inner wall of the ditch from long-term erosion by water flow, sediment, and debris, extending the service life of the ditch.

Stable crack resistance: Fiber skeleton enhances the toughness of concrete, reduces cracks caused by temperature changes and foundation settlement, maintains the integrity of ditch structures, and reduces the risk of collapse.

3、 Main features

Efficient construction: No complex processes such as formwork and mixing are required, and manual laying can be quickly carried out. After watering, it can be cured to 80% strength within 24 hours, and the construction efficiency is 5-10 times that of traditional concrete, especially suitable for narrow spaces or complex terrains.

Flexible adaptation: It can be cut and spliced freely, and can fit irregular ditches such as arcs and trapezoids. It is suitable for various scenarios such as repairing old ditches and new construction projects, reducing construction restrictions.

Economic and environmental protection: Small material transportation volume (roll packaging), low labor costs, and comprehensive cost savings of more than 30% compared to traditional materials; Low production energy consumption, no odor pollution, and some products can support vegetation growth while also considering ecological considerations.

Strong durability: acid and alkali resistance, good weather resistance, waterproof and fireproof, not easy to age, with a service life of 10-20 years in harsh environments, and low maintenance costs in the later stage.

Product Parameters

Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

Freeze-thaw | Residual initial flexural | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

Construction temperature conditions | Construction above 0℃ | ||||||

Fire protecting performance | B1 | GB 8624-2012 | |||||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

Copper (total copper) (mg/L) | ≤100 | ||||||

Zinc (total zinc) (mg/L) | ≤100 | ||||||

Cadmium (total) (mg/L) | ≤1 | ||||||

Lead (total lead) (mg/L) | ≤5 | ||||||

Total chromium (mg/L) | ≤15 | ||||||

Nickel (total nickel) | ≤5 | ||||||

Arsenic (total) | ≤5 | ||||||

Product Application

1、 Agriculture and Irrigation Engineering

Field irrigation ditch: directly laid on the inner wall of soil ditch and brick ditch, solidified to form an anti-seepage layer, reducing irrigation water leakage (leakage rate reduced by more than 60%), resisting sediment erosion, extending the life of the ditch, and adapting to the slope of the main canal, branch canal and water storage tank in farmland.

Rural drinking water project: repair old drinking water channels/pipelines, isolate soil pollution, ensure water quality, construction does not require large-scale excavation, high efficiency.

2、 Municipal and Drainage Engineering

Urban rainwater and sewage ditch: It conforms to the inner walls of underground rainwater ditches and sewage ditches, is impact resistant and wear-resistant, reduces concrete peeling and cracks, and does not require formwork during construction. It is suitable for working in small spaces and reduces interference with residents' lives.

Landscape water system/river: laid on slopes, waterproof against soil erosion, breathable products can support vegetation growth, balancing protection and ecology.

3、 Industrial and Special Engineering

Industrial wastewater treatment: acid and alkali resistant special cement blanket lining chemical and metallurgical wastewater channels, anti-corrosion leakage, protecting groundwater, with a lower cost than materials such as fiberglass.

Mine/yard drainage: resistant to high concentration sediment and gravel erosion, with better wear resistance than ordinary concrete, suitable for complex terrain in the wild.

4、 Emergency and Temporary Engineering

Flood prevention and rescue: Emergency installation in weak ditch sections, rapid solidification and anti-seepage reinforcement, completed flood control reinforcement in a few hours, with a response speed much faster than traditional methods.

Temporary drainage: Quickly build temporary drainage channels around infrastructure construction sites and campsites, which are easy to construct and can be recycled or environmentally degraded after the project is completed.

Cement ditch lining plays an important role in various fields such as agricultural water-saving irrigation, municipal drainage maintenance, industrial pollution protection, and emergency rescue, thanks to its flexible construction method and reliable protective performance. It provides efficient and practical solutions for ditch protection in different scenarios, effectively solving problems such as leakage, wear and tear, and complex construction in traditional ditches.