Super Geotextile

1.Multi-functional Integration: Simultaneously has multiple functions such as drainage, filtration, separation, reinforcement and protection, no need to match multiple materials, simplifying engineering design and construction processes.

2.Convenient and Efficient Construction: Lightweight and can be laid directly; high degree of size customization reduces on-site cutting waste, saving labor and time costs; simple lapping and fixing operations, suitable for construction in various complex terrains.

3.Significant Cost-effectiveness: Compared with traditional geotextile materials, it can reduce the comprehensive engineering cost by more than 30%; extend the service life of the project by more than 15 years, reducing the frequency and cost of later maintenance; large production capacity and short delivery cycle ensure project progress.

4.Stable and Controllable Performance: Produced in strict accordance with international and industry standards, with accurate mechanical performance (tensile, bursting, creep resistance) and hydraulic performance (permeability, filtration) indicators, and high consistency of batch production quality.

5.Eco-friendly: Made of environmentally friendly polymer raw materials, no harmful volatile substances; when applied in landscaping and agricultural scenarios, it can improve soil air permeability, promote vegetation growth, and be recyclable.

Products Introduction:

Super geotextile is a high-performance geosynthetic material made from high-strength fibers through advanced processes such as needle punching, thermal bonding, or weaving. Compared to traditional geotextiles, it adopts a special material formula and structural design, achieving comprehensive upgrades in mechanical properties, durability, and other aspects. Its appearance is smooth and uniform, with a tough texture, which can play a key role in various complex engineering environments and provide reliable guarantees for engineering construction.

Core Definition: Super Geotextile is a type of high-performance geosynthetic material made from high-quality polypropylene (PP) or polyester (PET) staple fibers/filaments through processes such as needle-punching and weaving. It has a stable fiber network structure, with core functions including drainage, filtration, separation, reinforcement, and protection.

Product Types: Mainly divided into two categories: non-woven (needle-punched type) and woven type. Among them, non-woven products can provide specialized small-width adhesive models and custom-width models for PVC pipe wrapping; woven products are graded by different ounces (4oz, 5oz, 6oz, 8oz, etc.) and grammage (100-800g/m²) to meet various engineering requirements.

Quality Standards: The products comply with international standards such as ASTM/DIN/EN and domestic infrastructure industry specifications including MORTH, RDSO, and NHAI. They undergo strict testing in the factory laboratory before leaving the factory to ensure performance meets standards.

Basic Parameters: Customizable width range: 0.1-5 meters; length can be supplied on demand; the longitudinal tensile strength of some woven products can reach 80kN/m, bursting strength exceeds 3.5kN, and permeability coefficient can reach 0.1cm/s, meeting the mechanical and hydraulic requirements of different projects.

Product Features:

1. High strength and toughness: Using high-quality high-strength fibers and special weaving techniques, super geotextiles are endowed with excellent tensile strength and tear resistance. When subjected to the tensile force generated by soil deformation, it is not easily broken or damaged, effectively enhancing soil stability.

2. Excellent puncture resistance: Through special surface treatment or multi-layer composite structure design, super geotextile has strong puncture resistance, which can resist the puncture of sharp objects such as gravel and tree roots, prevent local damage from affecting overall performance, and extend service life.

3. Efficient drainage performance: The unique three-dimensional pore structure forms a smooth drainage channel with excellent permeability. It can quickly discharge accumulated water in the soil, reduce pore water pressure, effectively avoid soil softening, settlement and other problems caused by accumulated water, and maintain the stability of the engineering structure.

4. Excellent corrosion resistance and aging resistance: the raw materials are added with special corrosion resistance components and treated with UV resistance, so that they can still maintain good physical properties and greatly reduce the cost of the whole life cycle in the chemical corrosive environment such as acid, alkali, salt, and the natural environment such as sunlight exposure and high and low temperature alternation.

5. Good construction convenience: Lightweight, flexible, easy to cut, transport, and lay, can greatly improve construction efficiency. At the same time, it has strong adhesion with the soil, can adapt to different terrains and engineering requirements, and reduces construction difficulty.

Structural Characteristics: Non-woven products form a three-dimensional fiber network through needle-punching process, with a porosity of over 40%, featuring both air permeability and filtration; woven products adopt unidirectional/bidirectional weaving process, with one side woven to enhance strength and the other side needle-punched to improve filtration, ensuring stable structure and uniform dimensions.

Material Advantages: Made of high polymer materials, it has excellent corrosion resistance (resistant to acids, alkalis, salts and other chemical media), oxidation resistance and moth resistance, and can maintain stable performance in humid and harsh environments.

Flexible Specifications: Grammage covers 100-800g/m², ounces cover 4-8oz; width and length can be customized according to project needs, supporting automatic slitting without on-site manual cutting, ensuring dimensional accuracy.

Strong Durability: Strengthened by online calendering process, it has excellent puncture resistance and tear resistance; some products have high UV protection level, service life can reach 25-50 years in underground burial environment, and can maintain more than 85% of initial strength in freeze-thaw cycle environment.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

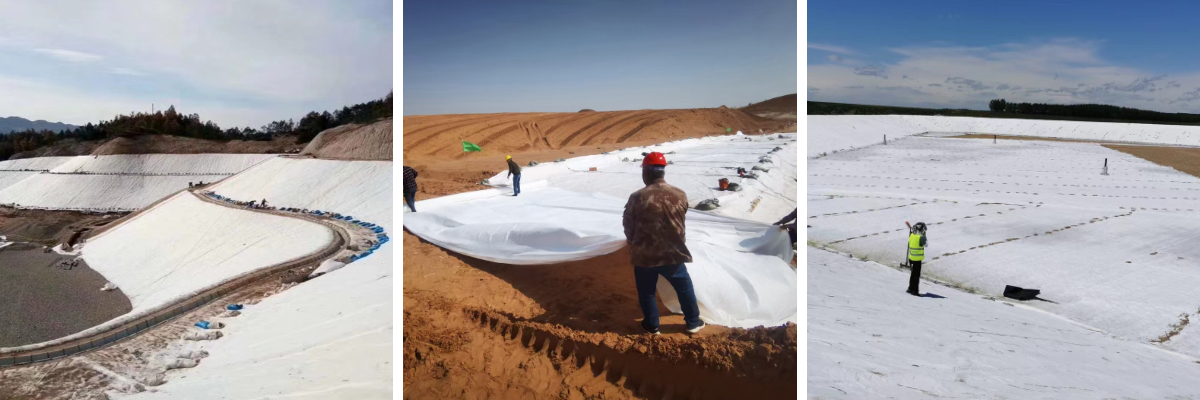

Road and Transportation Infrastructure: Suitable for subgrade reinforcement and interlayer separation of paved/unpaved roads such as expressways, national highways and rural roads; subgrade stabilization and drainage of airport runways and railway track laying; foundation reinforcement of parking lots and driveways, which can effectively inhibit reflective cracks and uneven settlement.

Water Conservancy and Flood Control Projects: Erosion protection of rivers and coastlines; reinforcement and drainage of dams and slopes; anti-seepage auxiliary layer of reservoirs and water storage tanks; water diversion and filtration of tunnel linings and underground drainage systems, which can quickly drain accumulated water and reduce the risk of dynamic water pressure erosion.

Environmental Protection and Waste Disposal: Drainage layer and filtration layer of landfills to block the diffusion of pollutants; anti-seepage separation and water quality filtration of sewage treatment plants; soil protection of industrial waste residue dumps to prevent leakage of harmful substances.

Landscaping and Agricultural Fields: Weed barrier (weed mat) for courtyards and flower beds; lining for planting beds and raised garden beds; optimization of soil air permeability and drainage of farmland drainage systems; ground protection of greenhouses.

Other Engineering Scenarios: Reinforcement and filtration of retaining walls; wrapping and filtration of French drains (perforated pipe drainage systems) and edge drainage systems; auxiliary protection such as hard armor cushions and pond linings.

Super geotextile is widely used in various fields such as roads, water conservancy, environmental protection, mining, etc. due to its outstanding characteristics of high strength, high toughness, puncture resistance, good drainage, corrosion resistance, and convenient construction. In engineering construction, it can not only significantly improve the quality and stability of the project, extend the service life of the project, but also reduce maintenance costs in the later stage, with extremely high cost-effectiveness and good economic and environmental benefits. Whether it is large-scale infrastructure construction or small-scale ecological restoration projects, super geotextiles have demonstrated strong adaptability and reliability, and are indispensable high-quality geosynthetic materials in modern engineering construction.