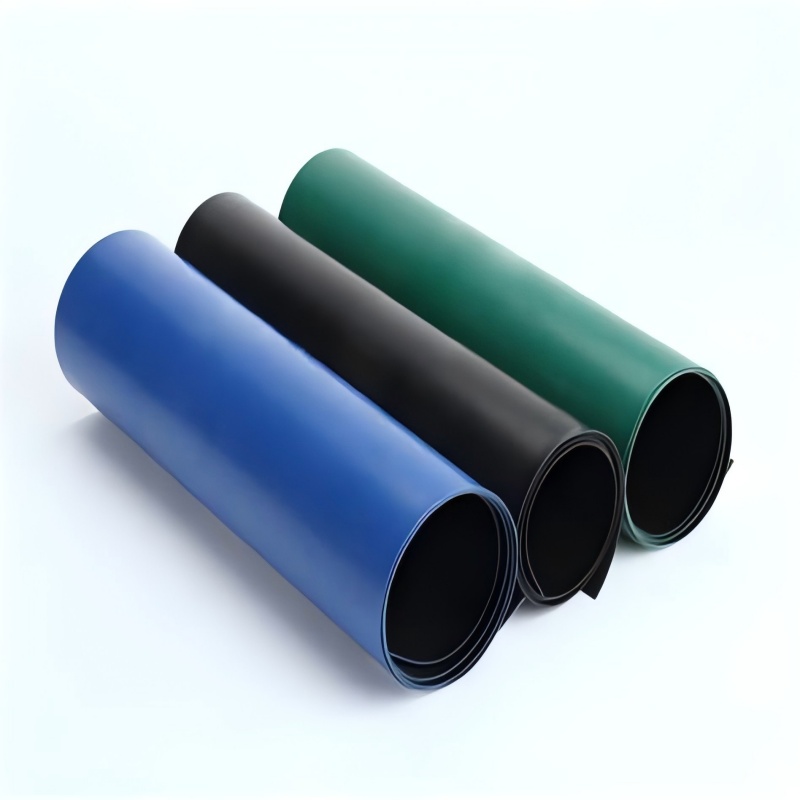

20 mil HDPE Liner

1. Excellent anti-seepage performance: Based on polymer materials, the molecular structure is dense, which can effectively block liquid penetration and reduce leakage losses.

2. Strong weather resistance and durability: outstanding anti-aging and UV resistance, which can be used in the open air for a long time; Simultaneously resistant to acid and alkali, corrosion-resistant, able to adapt to various complex chemical environments, and maintain stable performance.

3. Excellent mechanical properties: high tensile strength, strong tear and puncture resistance, able to adapt to deformation caused by foundation settlement, temperature changes, etc., not easily damaged, ensuring the integrity of the anti-seepage structure.

4. Convenient and efficient construction: The material is lightweight, the laying is flexible, the splicing method is mature, the construction speed is fast, and it can shorten the project cycle.

Product Introduction:

20 mil HDPE Liner is a waterproof and barrier material based on high molecular weight polymers. It is usually made of plastic film as the anti-seepage substrate and compounded with non-woven fabric to form a geotextile anti-seepage material.

Performance characteristics

1. Physical properties

There are various thickness specifications: the common thickness is generally between 0.2mm-2.0mm, which can be selected according to different engineering needs.

Small proportion: lighter in weight, easy to handle and construct.

Strong extensibility: able to adapt to a certain degree of deformation, not easily broken due to slight settlement or expansion of the foundation.

2. Chemical properties

Strong corrosion resistance: able to resist corrosion from more than 80 strong acidic and alkaline chemical media such as acid, alkali, salt, etc., and maintain stable performance in different chemical environments.

Good aging resistance: It has excellent aging resistance, UV resistance, anti decomposition ability, can be used naked, and the service life of materials is long.

3. Mechanical properties

High tensile strength: For example, HDPE geomembrane has a fracture tensile strength of over 28MP, which can withstand large tensile forces and is not easily broken.

Strong puncture resistance: It can resist the puncture of most plant roots and some sharp objects, protecting the integrity of the anti-seepage layer.

High tear resistance: When subjected to external tearing, it has high tear resistance and reduces the risk of damage.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

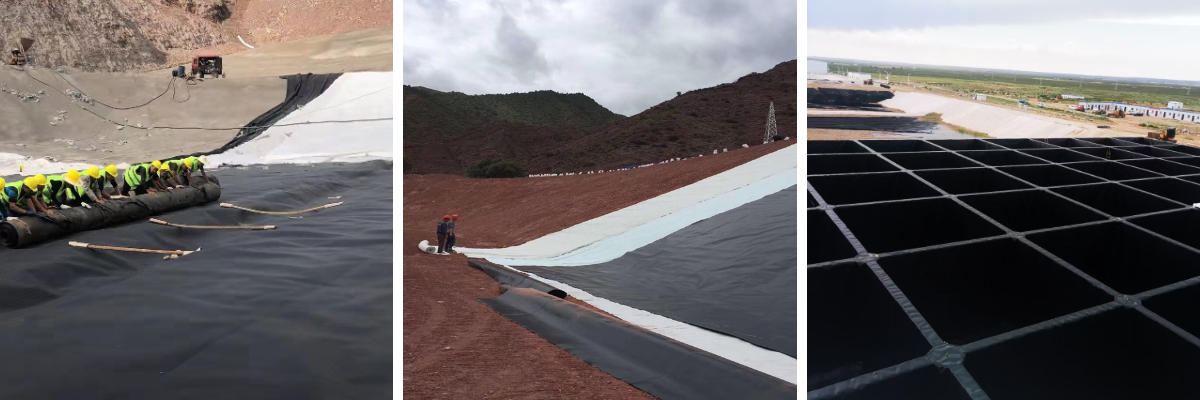

Product Applications:

1. Water conservancy engineering: used for anti-seepage of reservoirs, canals, artificial lakes, dams, etc., to prevent water leakage, ensure water stability, reduce water resource waste, and improve the safety and service life of water conservancy facilities.

2. Environmental engineering: In landfills, it can prevent soil and groundwater pollution caused by leachate from garbage; In sewage treatment plants, the treatment facilities are protected from corrosion by harmful substances, while also being used for anti-seepage in sewage tanks, regulating tanks, etc.

3. Transportation construction: applied to waterproofing of roadbeds and railways, anti-seepage treatment of tunnels, preventing groundwater infiltration, improving the stability and durability of roads and tunnels, and extending their service life.

4. In the field of agriculture: it can be used for anti-seepage in agricultural irrigation systems, reducing water evaporation and loss, improving irrigation efficiency, and saving water resources; It can also be used for anti-seepage of aquaculture ponds, maintaining stable water quality, preventing water resource loss and environmental pollution caused by leakage.

5. Construction engineering: Used as waterproof materials in building parts such as basements, roofs, bridges, etc., to prevent leakage, protect the building structure from water erosion, and improve the durability of the building.

Geomembrane, with anti-seepage as its core, combines economy, durability, and construction flexibility, and is the preferred material for modern anti-seepage engineering.